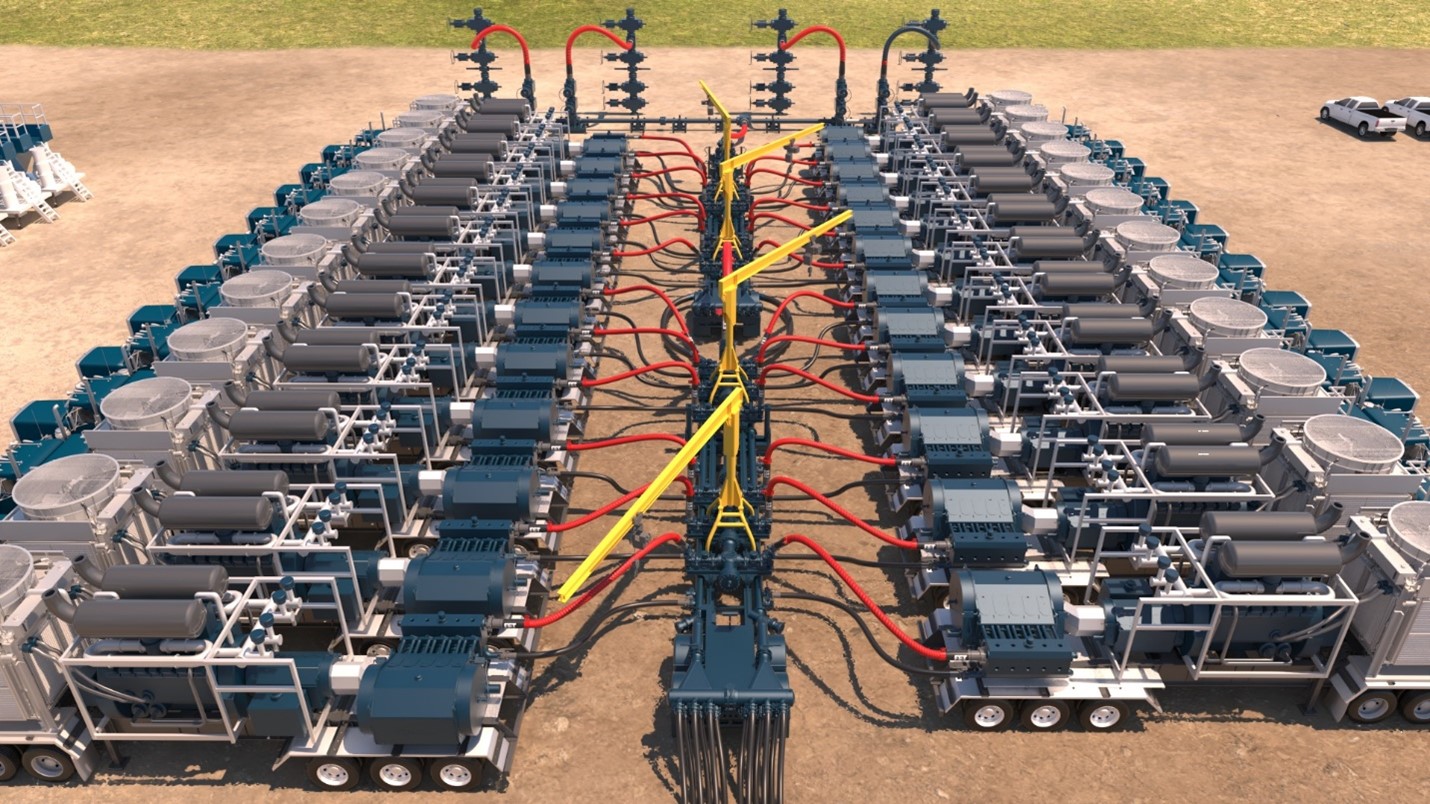

HydraLine™ Single-Line System: Smarter Pumping Starts Here

FET’s HydraLine Single-Line System transforms frac site operations with a streamlined, field-proven solution that enhances safety, reduces complexity, and accelerates setup. Designed to integrate seamlessly with any frac pad layout, HydraLine helps operators pump smarter with fewer connections, faster rig-up, and dramatically lower downtime.

Why HydraLine?

- 80% Fewer Connections: Simplifies setup and teardown while eliminating all hammer unions on treating iron.

- Up to 60% Faster Rig-Up/Rig-Down: Compared to legacy manifold systems, HydraLine saves valuable time and labor.

- Up to 90% Reduction in NPT: Minimize leaks and failures common in traditional iron arrangements.

- Lower Operating Costs: Fewer components, less maintenance, and longer asset life.

- Enhanced Safety: Fewer leak points and simplified layouts reduce risk onsite.

SMART DESIGN FEATURES

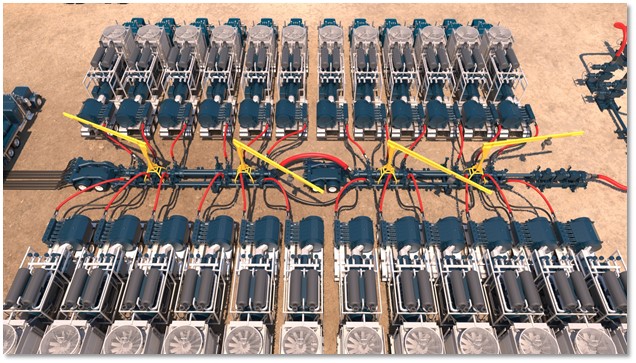

- Zero Hammer Union Connections

- Robust Hub-Style Iron Connections

- No Swivels or Pup Joints

- Optimized Pad Layout

- Vibration Dampening via High-Pressure Hoses

- Extended Life of Primary Components

OPERATIONAL BENEFITS

- Improved Safety Across the Pad

- Reduced Non-Productive Time

- Lower Recertification Costs

- Streamlined Logistics and Labor

- Improved Total Cost of Ownership

- Longer Equipment Lifespan

| Feature | HydraLine Single-Line System | Legacy Manifold Systems |

| Connection Count | 80% fewer connections | High number of connections |

| Hammer Unions | Completely eliminated | Numerous hammer unions prone to leaks |

| Rig-Up/Rig-Down Time | Up to 60% faster | Labor-intensive and time-consuming |

| Non-Productive Time (NPT) | Reduced by up to 90% | Frequent downtime due to leaks and failures |

| Safety | Enhanced through simplified layout and fewer leakage points | Higher risk due to complex iron arrangements |

| Fluid End Compatibility | Easily adaptable to any frac pad design | Often requires custom layout adjustments |

| Asset Longevity | Prolonged life of primary components | Increased wear and tear |

| Maintenance & Recertification | Lower costs due to fewer components | Higher costs and frequent recertification |

| Vibration Dampening | Integrated via high-pressure hoses | Limited or no dampening |

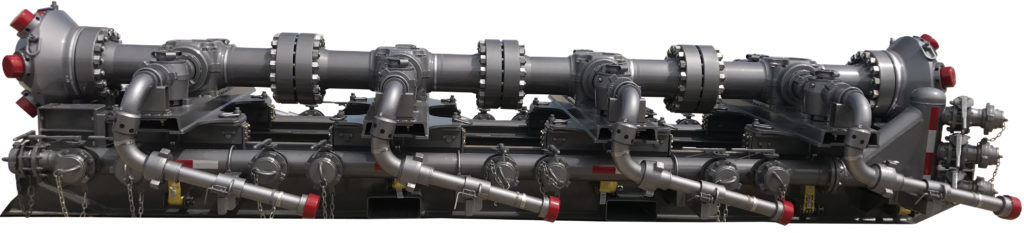

FET’s Manifold Trailers and Skid

Discover the next generation of frac operations with FET—where innovation meets reliability. Our standard manifold trailers deliver proven performance, while our groundbreaking ICBM Manifold Trailers and Skids redefine what’s possible in wellsite efficiency, safety, and uptime.

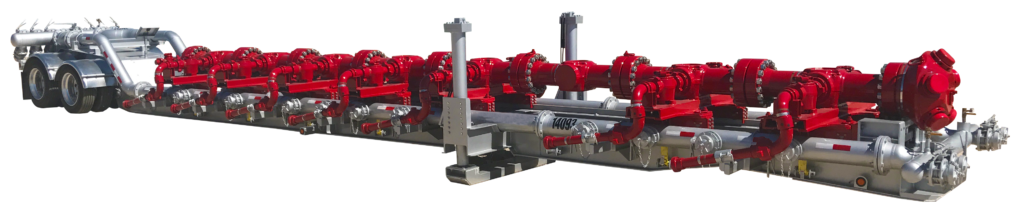

ICBM Manifold Trailer and Skid

Welcome to “Wellhead on a Trailer.” Welcome to ICBM.

At FET, we believe true innovation solves real challenges. The ICBM Manifold Trailer isn’t just a new take—it’s a game changer for the industry. Designed from the ground up to eliminate pain points in traditional manifold trailers, the ICBM seamlessly blends breakthrough engineering with trusted API 6A standards. The result: a trailer that delivers unmatched uptime, safety, and ease of use—outperforming anything else on the market.

ICBM Features:

- Superior Manifold Life

Our modular approach allows every station to be independently removed and rotated, making maintenance fast, straightforward, and reducing wear across the system. This extends manifold life and maximizes your investment. - Standard Components

Built with industry-standard components—including API 6A, 15K, 7-1/16”, and 6BX flanges—for easy integration and familiar operation. - New XD End Connection

Our patent-pending XD End Connection provides superior resistance to fatigue, side loads, and vibration, setting a new benchmark for reliability in demanding frac environments. - Easier & Safer to Work On

With 70% fewer connections and low-pressure lines routed underneath, technicians work at waist level or lower—making jobs safer, faster, and less physically demanding.

ICBM Skid

Leveraging the proven ICBM Manifold Trailer design, the 7-1/16” ICBM Skid enables rapid rig-up with our single-line trailer and supports connections for up to 24 pumps—delivering scalability and efficiency for even the largest jobs.

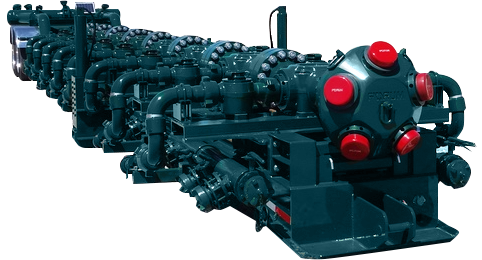

Standard Manifold Trailers

Our Standard Manifold Trailers cut hookup and disconnect times by up to 50% compared to conventional equipment, allowing you to move faster and capitalize on every opportunity.

Manifold Trailers are fabricated to customer specifications, or standard models are available for purchase.