Catwalks

Catwalks serve not only as the staging areas for your rig and drilling tool activities, but as crucial foundations in your overall safety strategy. A well-designed catwalk significantly reduces tubular handling and minimizes operating hazards, creating a safer, more efficient rig site.

As the premier manufacturer and supplier of hydraulic catwalks, FET continues to advance the safety and efficiency of drilling rigs all over the world. Our field-proven products minimize the hazards associated with direct tubular handling during the pickup and laydown processes, supporting your operations in all conditions and locations.

As the sole manufacturer and supplier of the respected Pipe Wranglers™ line of catwalks, our products combine a two-decade legacy of excellence with the latest engineering advancements to offer the most reliable catwalks in service today. Every detail, from mechanical innovation to meticulous fabrication, is designed to keep your rigs safe and productive while increasing profitability.

Hawker Pipe Handler / Hydraulic Catwalks

The Hawker Pipe Handler / Hydraulic Catwalk is your solution to increased safety, speed and efficiency when you are servicing a well. Everything on our Pipe Handler has been designed to help eliminate all your safety concerns. Our index arms will pick up the pipe right from the pipe racks so no manual labor is needed. Our hydraulic trough then raises the pipe to the sub-floor of the workover rig and the skate pushes the pipe to the rig hands. The Pipe Handler operator has the option of using the controls physically located on the on the machine, which are very simple to operate and easy to control. Workers can also use our state of the art wireless remote control. The Wireless remote allows the operator to be flexible and maneuver position to increase visibility.

The Hawker Pipe Handler can reach sub-floor heights of up to 40 feet. Combine that with the power of a Kubota engine powering the Hydraulic Catwalk unit, you have a machine that has the speed and power to more than keep up with your well service operation and increase overall efficiency. We have models that can handle range 2 and range 3 length tubulars with operating capacities of 2500 to 5500 lbs.

The Hawker Hydraulic machine reduces the need for manual labor when lifting the pipe to and removing from the service rig. Its speed and efficiency is designed to improve production times and reduce costs. The Hawker is simple to move from site to site. When you pull on to a job site the Hawker can be set-up and ready to go within minutes.

We take pride in our ability to provide comprehensive support to keep your operations running smoothly. Our service centers are strategically located to provide rapid, efficient support to customers worldwide. Our technicians are industry experts who undergo continuous training to stay abreast of the latest advancements in drilling technology. We are dedicated to ensuring optimal performance and uptime for your equipment, offering everything from routine maintenance to emergency repairs.

Why you need a Hawker Pipe Handler

Arrives Field Ready

Hawker delivers your unit ready to perform with a turnkey design, intuitive control layout and a low learning curve.

Fast ROI and Financing

The Hawker Pipe Handler quickly pays for itself. Need quick financing approval? We can help.

Decrease Mobilization Time

Ready to go in minutes. Complies with all DOT regulations and can be moved with a medium-duty truck.

Pipe Handler Features

Height Adjustment system (Patented)

We have a pinless height adjustment system that allows us to go from the lowest to highest setting in less than a minute. Our hydraulic set-up allows you to easily adjust height with ease while you are in the field.

Synchronized Index arms

Our index arms that lift the pipe from the pipe rack are synced together..which allows pipe to lift and roll evenly on and off the Pipe Handler.

Synchronized flippers

Our flippers are synced together to allow even removal of pipe out of the trough.

Designed and Engineered for quick preventive maintenance

Parts are available for next day delivery on our shelf. No special orders needed. The Pipe Handler was designed for quick and easy repair with the operator and mechanics in mind.

Heavy duty, fast and efficient

The Hawker Pipe Handler was designed to withstand the every day wear and tear of the extreme elements that it will be operated in. The speed and efficiency of our machine will help increase productivity and reduce operating costs.

Mobility

All Hawker Pipe Handlers are DOT compliant for highway travel.

Features

- Made in the USA

- Supporting Energy Independence

- Safer Way to Handle Pipe When Pulling or Placing

- Your Crews Will Appreciate The Performance & Safety Hawker Provides

- Built to Last

- Designed for Tubular Protection

- Built From the Ground Up

- Quick Return on Investment

- Department of Transportation Compliant

- Heavy Duty and Yet Light Enough to Haul

- Simple to Operate

- Designed and Engineered for Quick, Preventive Maintenance

- Custom Paint to Brand Your Company

- Set Up and Tear Down Quickly

Features Cont.

- Safe & Efficient

- Reduced Costs Through Efficiency

- Remote Control Included

- We Can Customize Your Unit to Fit Your Needs

- This Unit Arrives (Turnkey) Field Ready

- Custom Manufacturing Available

- Training Provided

- Maintenance Plans Offered

- Minimizes Injuries and Workmen’s Comp Claims

- Full Time Hydraulic Filtration System

- Patented Pinless Height Adjustment System (TL-40)

- Patented Pipe Grabber for Making Swivel Connections

- Patented Wedge System to Increase Angle of Trough to Reach Higher Floor Heights

Hawker Training

Upon purchase of our Hawker Pipe Handler the Owners and operators will be provided the following:

Training in operation and set-up. The operators will be trained on how to properly set-up the machine on-site and receive step by step instructions on how to operate every control.

The owners and operators will receive owners manuals with detailed description of all components and operating procedures.

Owners and operators will receive contact information for all sales and service techs so if any questions arise they can contact immediately.

Company repair technicians will receive training on how to properly service and maintain machine to help minimize down time and maximize the Pipe Handlers efficiency.

Little Tripper

Forum’s newly redesigned Little Tripper™ portable catwalks support pipe pickup and laydown, efficiently delivering tubulars to the rig floor and back on well service and land rigs. Since these versatile units can accommodate working platforms from four to 40 feet, they support traditional operations for well servicing, casing and tubing running services and in snubbing-assisted completions in shale drill-outs and workovers. Available in both trailer-mounted and skid-mounted versions, they can handle tubulars up to 45’ in length and be fully operational in only a few minutes.

Benefits

- Removes critical operations personnel safely away from all hazard zones

- Field-configurable to fit any installation from 4 to 40-foot delivery requirement

- Accommodation for all heights of pipe racks, including stacked rows

- No rig power or interface required

- V-door not required

- Tubular delivery up to 45 feet in length

Features

- Standard onboard hydraulic controls with one wired (100-foot) remote control unit

- Robust, adjustable delivery height system

- Self-contained, integrated tier 4 diesel hydraulic-powered unit

- Trough skate to push and receive tubulars along the full length of the trough

- One each 10-foot extension (28-foot trough height)

- Interlocked trough kickers to prevent inadvertent operation when trough moves from home position

- Hydraulically deployed stabilizing system

- Hydraulically synchronized indexers and kickers

- Three work lights

- Quick-exchange interlocking trough extensions

Options

- Wireless controller

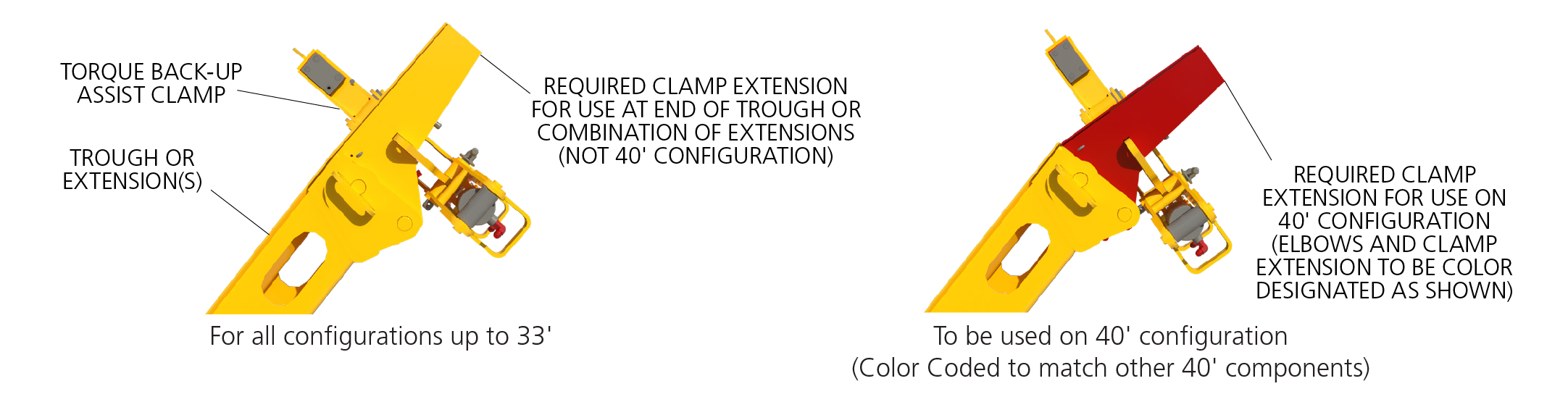

- Additional 10-foot trough extension (to reach 33 feet)

- Extended reach to 40 feet

- Cold weather operations package

- Cold weather storage package

- Desert package

- Power Swivel Assist Feature — includes controls integration of a mechanical arm to provide backup to the power swivel thread makeup in the trough

Mariner Series

Forum’s Mariner™ hydraulic catwalks are designed to work in offshore environments and handle all tubulars including drillpipe, bottom hole assemblies, tubing, casing and risers. Customized to meet your rig’s specific requirements, these rugged catwalks offer a unique retracting design that allows maximum crane access to all areas of the pipe deck.

In addition to the Mariner products, all of Forum’s land rig hydraulic catwalks can be utilized in the offshore environment on request, including the Wrangler™ and Tripper™ Series.

Features (Mariner 2500 Series)

- Suitable for rig floor heights up to 25 feet

- Suitable for tubular sizes up to 20 inches

- Skate system for pushing/pulling pipe from well center

- Local manual/direct hydraulic operation for emergency lowering of trough

- Remote podium control operation from drill floor

Features (Mariner XLR Series)

- Integrated hydraulic power supply

- Suitable for tubular sizes up to 30 inches

- Dual carrier system for safe, efficient, damage-free conductor handling

- Fully integrated skate system for pushing/pulling pipe from well center

- Integrated hydraulic traverse moving system to match configured drilling position changes

- Remote podium control operation from drill floor

- Local manual/direct hydraulic operation for emergency lowering of trough

- Integrated three-and-a-half ton winch for manual operations

- Drag chain and guidance system for utility feed to the unit

Both the Mariner 2500 and XLR models include numerous features that are standard on all of Forum’s hydraulic catwalks, along with extensive optional features. Standard features include:

- Hydraulic leveling systems

- Non-skid walking surfaces

- Patented integrated skate system

- Kickers that facilitate automated pipe unloading – to either side

- Hydraulic gull wing pipe racks

- Tiering system to accommodate stacked casing and tubing

- Safety perimeter e-stop

- Tubular laydown shovels

- Podium-style controls

Wrangler Series

Pipe Wranglers hydraulic catwalks play an integral part of step change efficiency gains and safety in today’s land rigs.

Designed for larger well servicing and drilling rigs, FET’s Pipe Wranglers models 2000/3000/4000/5000 hydraulic catwalks are capable of handling tubulars up to 10,000 pounds with cycle times of approximately 30 seconds. Featuring numerous options and safety features, this catwalk series reduces typical drilling rig hazards and provides safer, more economical environments than conventional methods of pipe handling.

All models of land rig hydraulic catwalks can be utilized in the offshore environment upon request.

Standard Features

- Rig floor heights up to 20 feet (Pipe Wranglers 2000)

- Rig floor heights up to 30 feet (Pipe Wranglers 3000)

- Rig floor heights up to 39 feet (Pipe Wranglers 4000)

- 6.5+Pipe – 4500

- Load handling up to 16,000 pounds

- Hydraulic leveling system

- Non-skid walking surfaces

- Patented integrated skate system

- Kickers that facilitate automated pipe unloading – to either side

- Hydraulic gull wing pipe racks (1 set)

- Tiering system to accommodate stacked casing and tubing

- Perimeter e-stop system

- Tubular laydown shovel

- Strobe light

- Safe trough stop

- Podium-style controls

Optional Features

- Wireless remote control

- Outrigger stabilizers

- Environmatting

- Catwalk crawler

- Tool basket

- Multi-position front arm

- V-door (conventional or hydraulic)

- Casing size over 20 inches

- Diesel hydraulic power unit

- Removable snow panels

- Special options available on request

Pipe Wranglers Model 4500

The Wrangler™ 4500 is Forum’s newest addition to our extensive line of hydraulic catwalks. Safety and efficiency are at the forefront of this design, which caters specifically to high drill floors in areas with extremely high formation pressures..

Increased safety is a primary focus of the 4500, with numerous options to support this effort. For example,

- Optional wireless control removes rig personnel from potentially hazardous areas.

- Proximity sensors detect pipe presence at the end of troughs, creating an interlock that prevents unexpected pipe movement.

- Loaded pipes can not accidentally be ejected from troughs during pickup and laydown processes, and

- All interlock mechanisms securely maintains pipes until the tubulars are at optimal presentation.

The Wrangler 4500 operates on a free-standing, single-chassis design that increases efficiency, while remote and condition-based monitoring services provide real-time data acquisition. This feature helps you prioritize potential repairs, leading to reduced maintenance costs and increased equipment lifetime.

Features

- 16,000 lbs V-door capacity option available

- 10,000-pound capacity (16,000-pound option available)

- Tubular range up to 30-inch casing

- Wireless control option

- Remote connectivity and condition-based monitoring

- Radio-frequency identification (RFID-enabled)