Choke/Control Valves

Maximizing production is a non-stop balancing act among the extremes of pressure, temperature and erosion. To help keep the best possible control of your wells, Forum manufactures a broad range of choke control valves to meet applications ranging from basic manual to fully automated systems.

Used extensively throughout the oil and gas industry, the quarter-turn and low-torque features of our patented BTE/BAP valves make them ideally suited for actuation. All of our valves hold ISO 9001:2015 and American Petroleum Institute (6A/6D/Q1) certification that ensures the highest design and manufacturing quality. Forum’s online sizing program can also help you conveniently choose the proper valve selection for your operation.

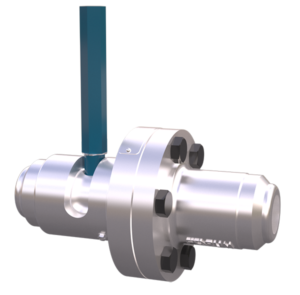

Model BTE/BAP Angle Pattern

The trim assemblies for the inline and angle pattern valves (Models BTE/BAP) are interchangeable. The top-entry design enables quick conversion from manual to automated and easy access to replace internal parts while in the well flow line.

Features

- Two- and three-inch sizes

- Easily actuated, low torque

- American National Standards Institute 600-2500 connections

- Corrosion-resistant body materials of high-strength cast steel, 316 stainless steel (SS)

- Tungsten carbide or ceramic discs for extreme erosive service

- Staged pressure drops to inhibit freeze-up for natural gas service

- Replaceable body sleeve

- Multiple orifice sizes available

- Impinging 180-degree flow characteristics

- Optional tungsten carbide wear sleeves for high-pressure drops

- Optional sealing components for sour gas service

Inline Choke Valve

Forum’s inline choke valve, formerly the Delta inline choke valve, is designed specifically for controlling gas and liquid flowline rates. Manufactured in stellite, a cobalt-chromium alloy, the sleeve absorbs the cavitation and pitting action of fluid as it takes the pressure drop and directs flow back into the center of the piping.

Features

- One- and two-inch sizes

- A487 carbon steel, nickel aluminum bronze, 316 SS

- Threaded, ANSI 600-1500 flanged

- Tungsten carbide or ceramic discs

Model BEAP

This economical, angle-pattern choke control valve is designed for longevity, performance and versatility. The self-impinging flow path diverts erosive kinetic energy away from the valve, while a pressure relief port increases operator safety by ensuring a depressurized valve before dismantling.

Features

- Two-inch size

- A487 4D alloy steel body for double body strength

- Standard-service ceramic disks, erosive-service tungsten carbide disks

- Gas blowdown line

- Automated line heater choke

- National Pipe Thread connection

- Bonnets designed to incorporate actuator brackets

- Optional tungsten carbide-lined port

- Optional actuation kits