BTEX Eliminator

A BTEX condenser unit (or BTEX eliminator) removes BTEX fractions from the Dehy still column overhead stream. BTEX is an acronym for benzene, toluene, ethylbenzene, and xylenes. These compounds are some of the most volatile organic compounds found in petroleum derivatives, such as petrol. The removal of toluene, ethylbenzene, and xylenes is vital as these compounds are carcinogens and have harmful effects on the environment.

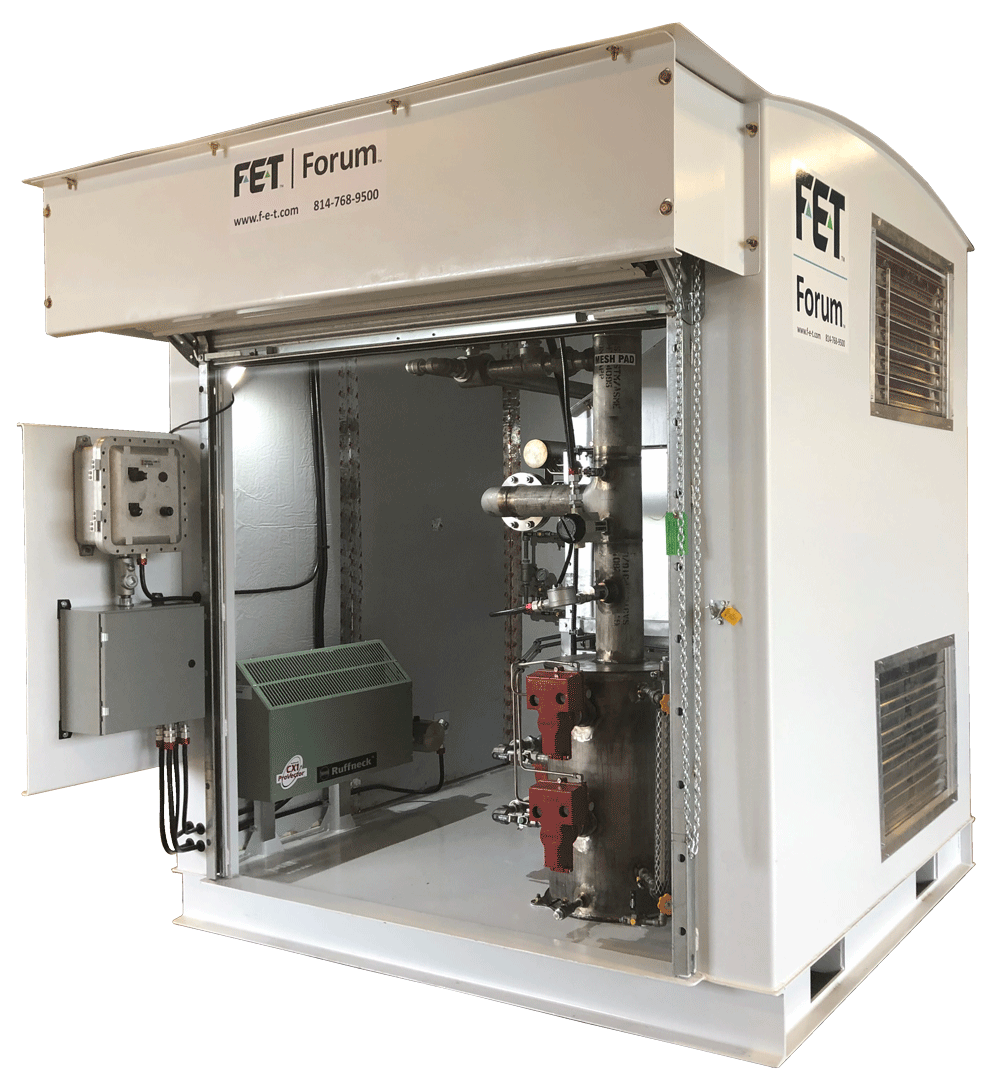

A BTEX condenser unit consists of a still overhead condenser, a liquids tank, and pneumatic or electric pumps to transfer the condensed liquids to storage tanks. Depending on the nature of the still overhead stream, the non-condensable vapors can be routed back to the reboiler for ignition in the stack. If these vapors prove too rich to burn in the firetube, they will be combusted in a flare or incinerator.

FET offers standard air-cooled BTEX condenser units, such as natural draft (A-frame) and forced draft condensers. We also offer shell and tube exchanger units, which use glycol as a cooling medium for applications in cold climates. BTEX units can also include enclosures, providing an addition layer of protection in cold temperatures.

Features:

- Engineered and designed according to ASME Section VIII Div. I & ASME B31.3

- FET manufactures, inspects, tests, and assembles in-house 100% of products

- Compact unit

- User-friendly design with field crew safety in mind

- Available with pneumatic or electric pumps

- Onsite startup & commissioning are available

- Available with a cold-weather package