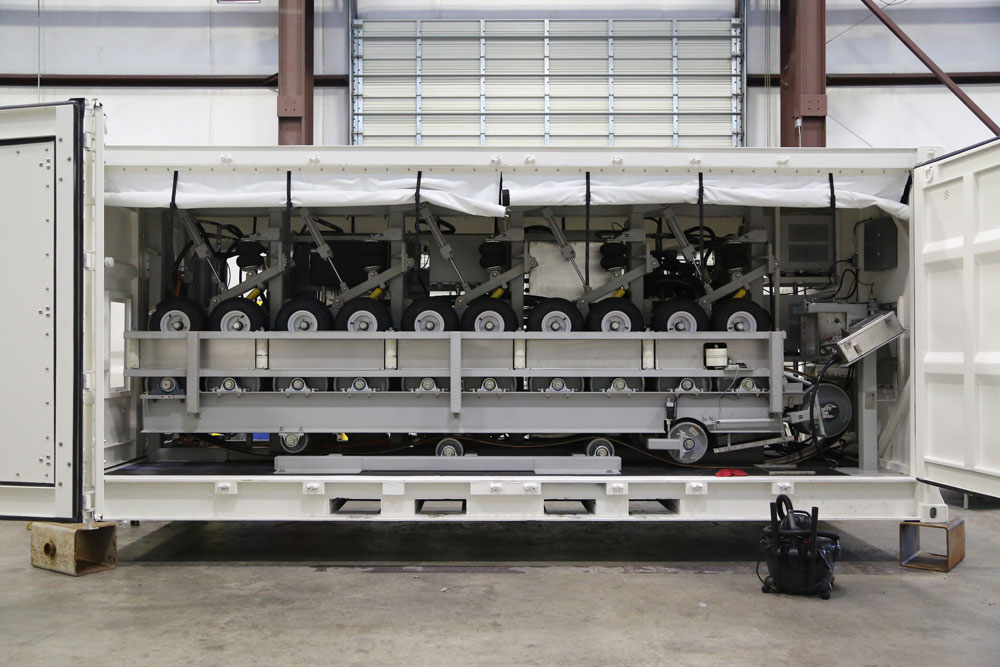

Linear Cable Engines (LCE)

FET’s Dynacon product line provides Linear Cable Engines for subsea applications to facilitate cable handling with two designs incorporating either track tensioners or standard wheel power modules.

Features & Benefits

- Containerized Modular design

- Standardized with exchangeable components

- Designed for easy integration

- Optimized efficiency and decreased necessary deck capacity

- All structural components are painted carbon steel

- Integrated control system

- Electrically/hydraulically driven

- Low noise operation

- Fully integrated with vessel control system

Options

- Side-loaded versions

- Wide-opening versions

- Service and maintenance program

- Spare parts package

- Remote control

- Wireless remote control

- Pinch status

- Extra high speed

- Complete control system monitoring

- Complete control system data log

- Tarpaulin cover

Model 5K Linear Cable Engine (LCE)

- Safe Working Load = 5,000 lbf

- Line Speed = 1,215 feet / minute

- Integrated lateral supports

- Side loading of cable, (optional customer container)

- Optional belt materials for ideal matching with cable jacket, (testing required)

- Electric Drive

- Linkable for control of multiple units to achieve increased outboard line tension

- Liquid cooled drive system components with integral chiller and external heat exchangers (to be mounted outside container by customer)

- Hydraulic power for lifting and tensioning mechanisms

- Air power for squeeze loads

- Pass up to 7” body / union at full speed

- Pass up to 14” body / union at reduced speed

- Installed into 20’ ISO container

Model 1.2K Linear Cable Engine (LCE)

- Safe Working Load = 1,200 lbf

- Line Speed = 1418 feet / minute

- Max normal load per tire = 500 lbf

- Integrated Dragboard on entry into LCE

- Optional belt materials for ideal matching with cable jacket, (testing required)

- Electric Drive

- Computer linkable for control of multiple units for increased outboard line tension

- Liquid cooled drive system components with integral chiller and external heat exchangers (to be mounted outside container by customer

- Hydraulic power for lifting and tensioning mechanisms

- Air power for squeeze loads

- Installed into custom 20’ ISO container