Advanced Coating Technology

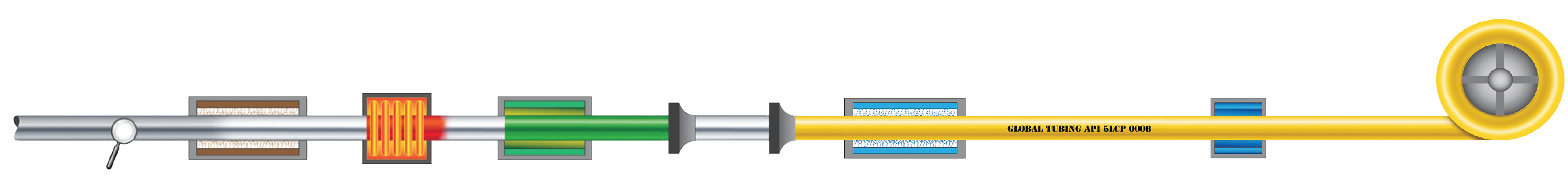

Three layer pipe coating systems for the exterior protection of steel pipelines have been used in the oil and gas industry for more than 20 years. The three-layer systems offer the advantages of mechanical, chemical, and electrical resistance of the polyolefin top-coat in combination with the excellent adhesion of epoxy to metal. The standard system being offered by Global Tubing for coiled line pipe consists of the following:

- A fusion bonded epoxy primer applied to a prepared steel surface

- An adhesive copolymer tie layer

- An extruded polyolefin top-coat (typically high density polyethylene or alternatively polypropylene for high-temperature applications) as required to achieve the required total coating thickness

The Global Tubing coating manufacturing layout (pictured above) is the most advanced system in the world and utilizes a fully integrated milling and coating operation.

Coating Properties & Parameters

| Coating Type | Max Temperature | Anti-Corrosion | Rocky Terrain | Subsea | Horizontal Directional Drilling | Thickness Ranges | Color |

|---|---|---|---|---|---|---|---|

| FBE | 230°F/110°C | YES | NO | YES | NO | 8-18 mils | Green |

| 3LPE | 185°F/85°C | YES | YES | YES | YES | 51-120 mils | Yellow / Black |

| 3LPP | 248°F/140°C | YES | YES | YES | YES | 51-120 mils | White |

| ARO | 230°F/110°C | YES | YES | YES | YES | 21-31 mils | Brown |