Offshore Applications

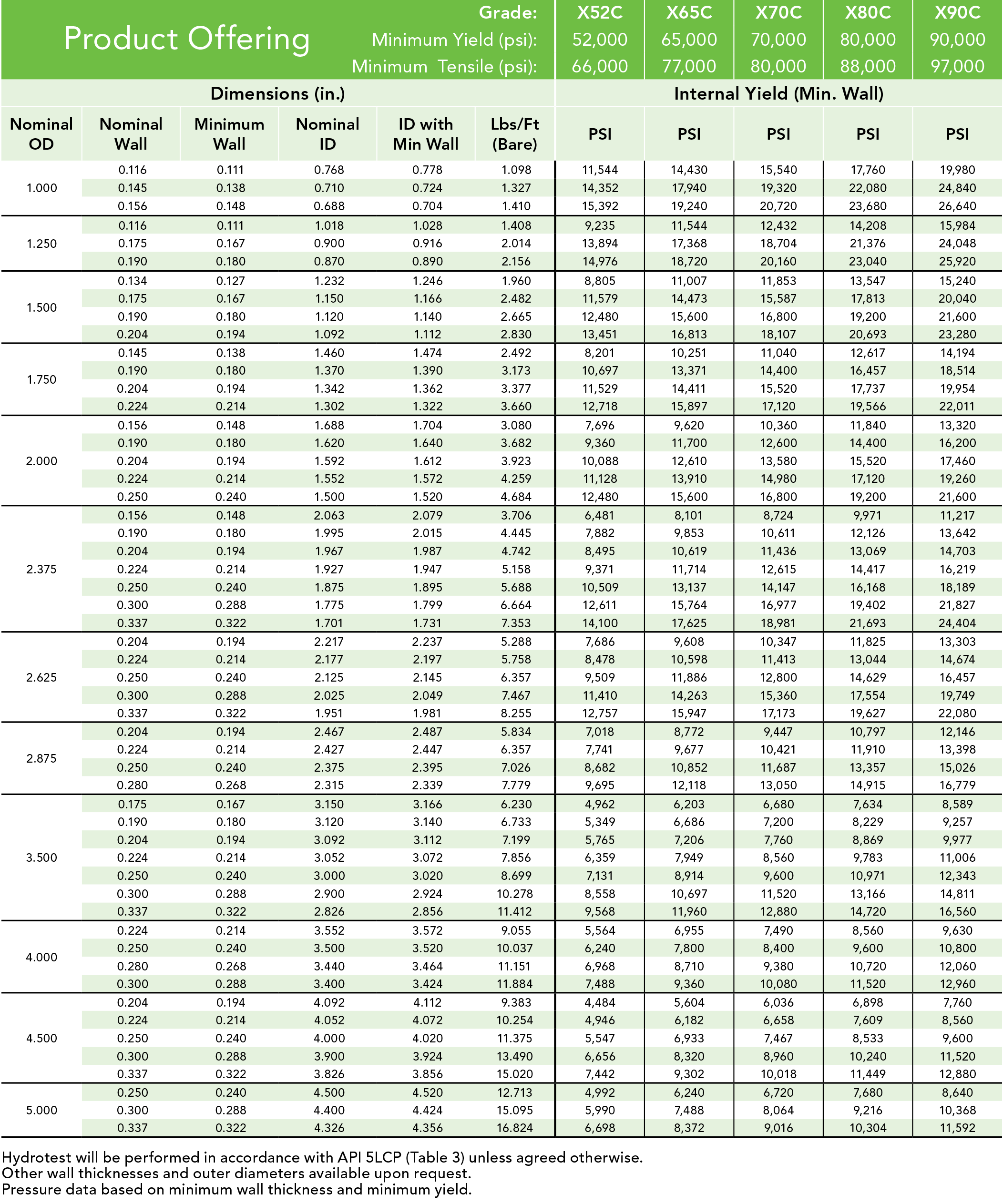

Global Tubing provides an excellent alternative to conventional 12-meter length line pipe. By removing critical path items such as joint welding, X-ray inspection, heat treat and field joint coating from the field process, Global Tubing’s coiled line pipe technology greatly reduces installation times and the associated costs with large offshore installation crews. Global Tubing’s Coiled Line Pipe is available in outside diameters up to 5 inches and a range of wall thicknesses that can be utilized in applications with pressure ratings beyond 15,000 psi and in shallow, deep and ultra-deep field developments.

Why use coiled line pipe offshore?

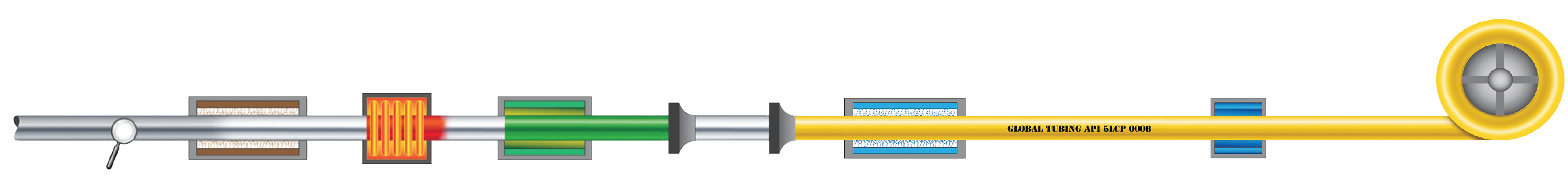

- Flexible deployment options are available such as direct lay from the shipping reel or consolidation onto larger carousels and vertical reels

- State-of-the-art 3-Layer Polyethylene (3LPE) coating provides unrivalled subsea protection for the pipeline during installation and for its design life

- 3-Layer Polypropylene (3LPP) coating is available for high-temperature requirements

- Long, continuous pipe lengths can be utilized in directional bore pulls or in beach crossings for quick and less risky deployment

Where can I use coiled line pipe?

- Subsea Flowlines and Pipelines

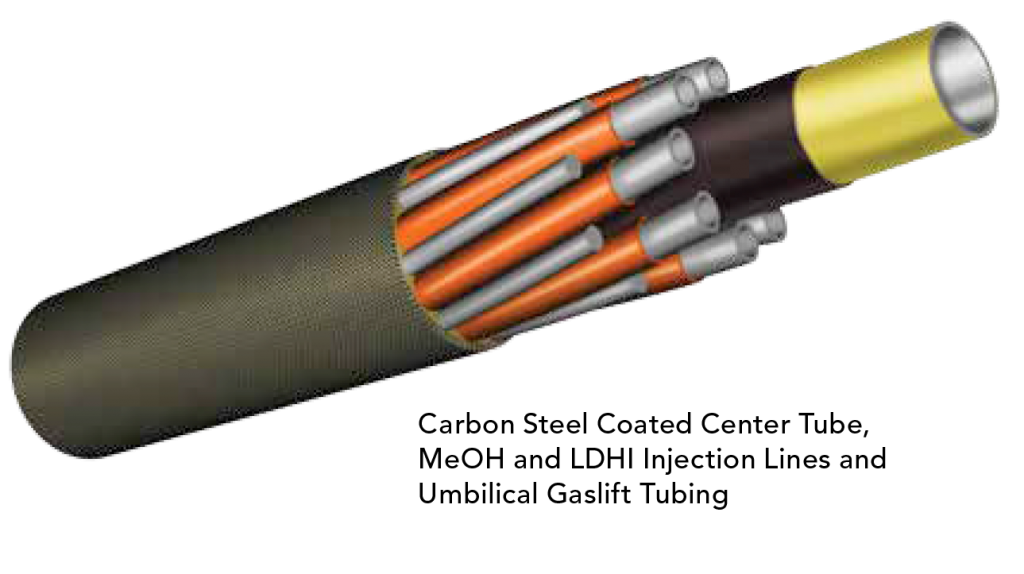

- Standalone or Piggyback Chemical Injection Lines

- Umbilical Applications

Qualifications and certifications

- Standard bearing HSEQ recognized by API Q1 and ISO 9001 certifications

- Peace of mind provided by API 5LCP monogram (License No. 0006)

- The 3-Layer Polyolefin (3LPO) pipe coating is compatible with the following industry standards:

> ISO 21809-1

> DIN 30678

> NFA 49-710

> NFA 49-711

> CSA Z245.20-10

> AS 1518