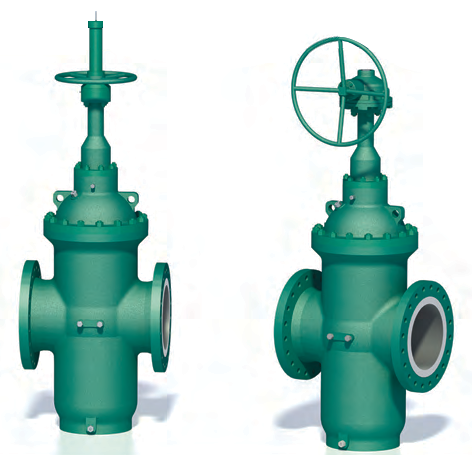

API 6D Gate Valve

Forum’s PBV® through conduit valves (6D gate valves) are engineered to use line pressure force for tight mechanical sealing on the upstream side when high differential pressure occurs. Internal springs achieve low-pressure sealing as they help push seat rings against the gates.

These bi-directional, double block-and-bleed slab gate valves are through conduit, piggable and top entry. Suitable for transportation pipelines for gas, crude oil and oil products, all valves are available in a variety of materials and configurations to meet your project requirements.

Benefits

- Chevron-style polytetrafluoroethylene (PTFE) packing for long-lasting, trouble-free stem sealing

- Seats to ensure low- and high-pressure sealing and body cavity self-relief

- Stem injection fitting for secondary sealing

- Smooth, electroless nickel-plated slab for bubble-tight sealing and low operating torque

- Seat injection fitting with internal check valve for emergency sealing

- Drain valve for block-and-bleed function and seat integrity verification

- Valve serialization for complete traceability

- Stem design with internal stops to prevent over-track of slab (no adjustments required)

- Secondary metal-to-metal sealing for fire-safe requirements

Features

- Full bore, through conduit, bi-directional flow

- Product range: two to 24 inches

- Full port

- Pressure class: American National Standards Institute (ANSI) 150, 300, 600

- Flange standards: American Society of Mechanical Engineers/ANSI B16.5, B16.47

- Face-to-face dimensions meet American Petroleum Institute (API) 6D standards

- Basic designs, inspections and testing also meet API 6D standards

- Fire testing to API 6FA standards

- National Association of Corrosion Engineers-compliant nuts and studs (MR0175 2015)