Tackle Gas Slugging Before It Disrupts Production

Gas slugs can form under a wide range of production conditions, whether due to shifting reservoir dynamics, enhanced oil recovery (EOR/IOR) strategies, or fluctuating production rates. Regardless of the cause, slugging remains one of the most persistent and costly challenges in the oil and gas industry.

This issue is particularly critical in unconventional wells that utilize artificial lift technologies, such as electric submersible pumps (ESPs). Gas slugs can lead to lost production, equipment damage, and increased operational costs, ultimately delaying the incremental production that optimized ESP systems are designed to capture.

The Best Solution Is Prevention

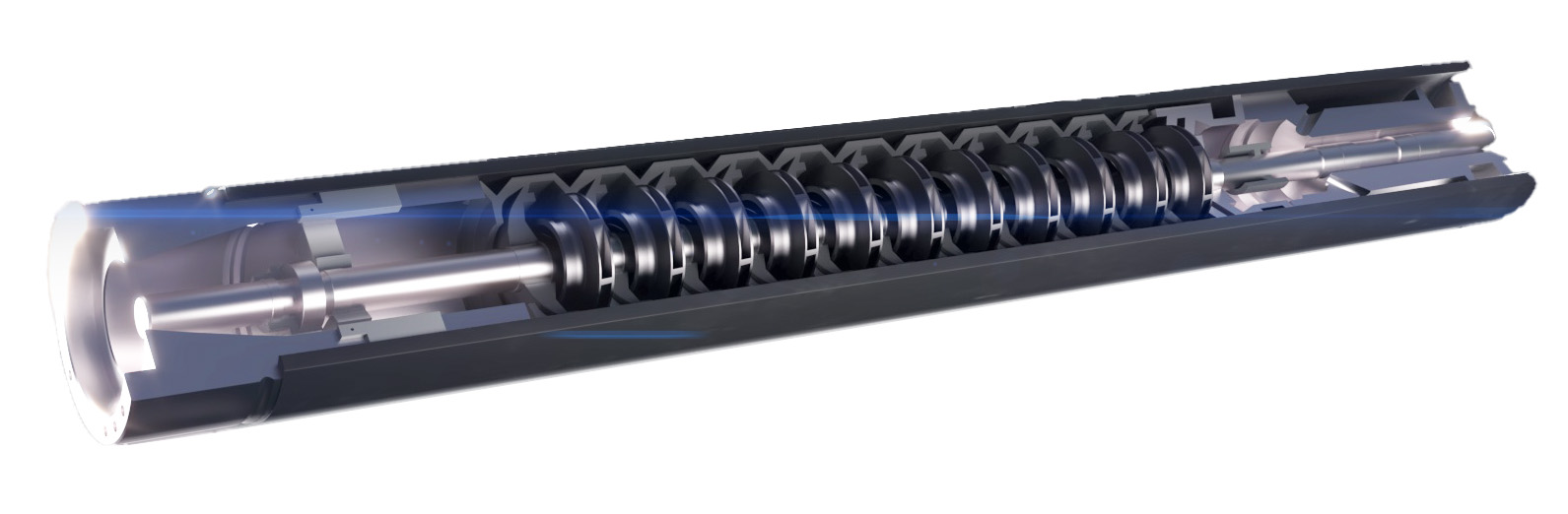

That’s where FET Multilift Solutions steps in. Our patent-pending GasGuard® neutralizes gas slugs before they reach the ESP system. By breaking down and infusing gas slugs into the liquid stream, GasGuard ensures a smooth, uninterrupted flow through the pump. The result? A more stable production stream with higher liquid content, improved motor cooling, and enhanced ESP performance with fewer shutdowns and lower maintenance costs.

With its streamlined, no-moving-parts design, GasGuard sets a new standard in gas slug protection.

Benefits

- Easy installation and retrieval via the production string

- Boosts ESP motor cooling efficiency

- Reduces equipment costs with a simplified design

- Disrupts gas slugs before they reach the pump intake

- Enhances pump runtime and overall performance

- Minimizes shutdowns caused by gas lock

- Complements or reduces reliance on costly ESP gas-handling devices

Key Features

- No moving parts for enhanced reliability

- Modular design suited for extreme environments

- Integrates with SandGuard™, Cyclone™, and chemical injection centralizers

Applications

- Unconventional wells

- Steam-assisted gravity drainage (SAGD) wells

- Wells experiencing severe gas slugging