Power Ends Engineered for Relentless Performance

At FET, we don’t just build power ends, we engineer endurance. We design power ends to thrive in the harshest frac environments, delivering consistent, high-output performance that operators rely on. With industry-leading durability and precision, FET builds power ends to reduce downtime and maximize ROI.

Why FET Power Ends?

- Unmatched Reliability: Designed to outperform and outlast in extreme conditions.

- Innovative Engineering: We optimize every component for strength, efficiency, and serviceability.

Whether you’re upgrading your fleet or planning for long-term operations, FET power ends give you the confidence to push harder and go further.

Frac Pump Repair & Service You Can Trust

Keep your operations running strong with FET’s expert frac pump repair services. Our certified technicians ensure fast turnaround times and precision repairs using OEM components, so your equipment gets back in the field faster and stays there.

- OEM Expertise: Repairs backed by original engineering standards and a six-month workmanship guarantee.

- Rapid Response: Minimized downtime with efficient diagnostics and service.

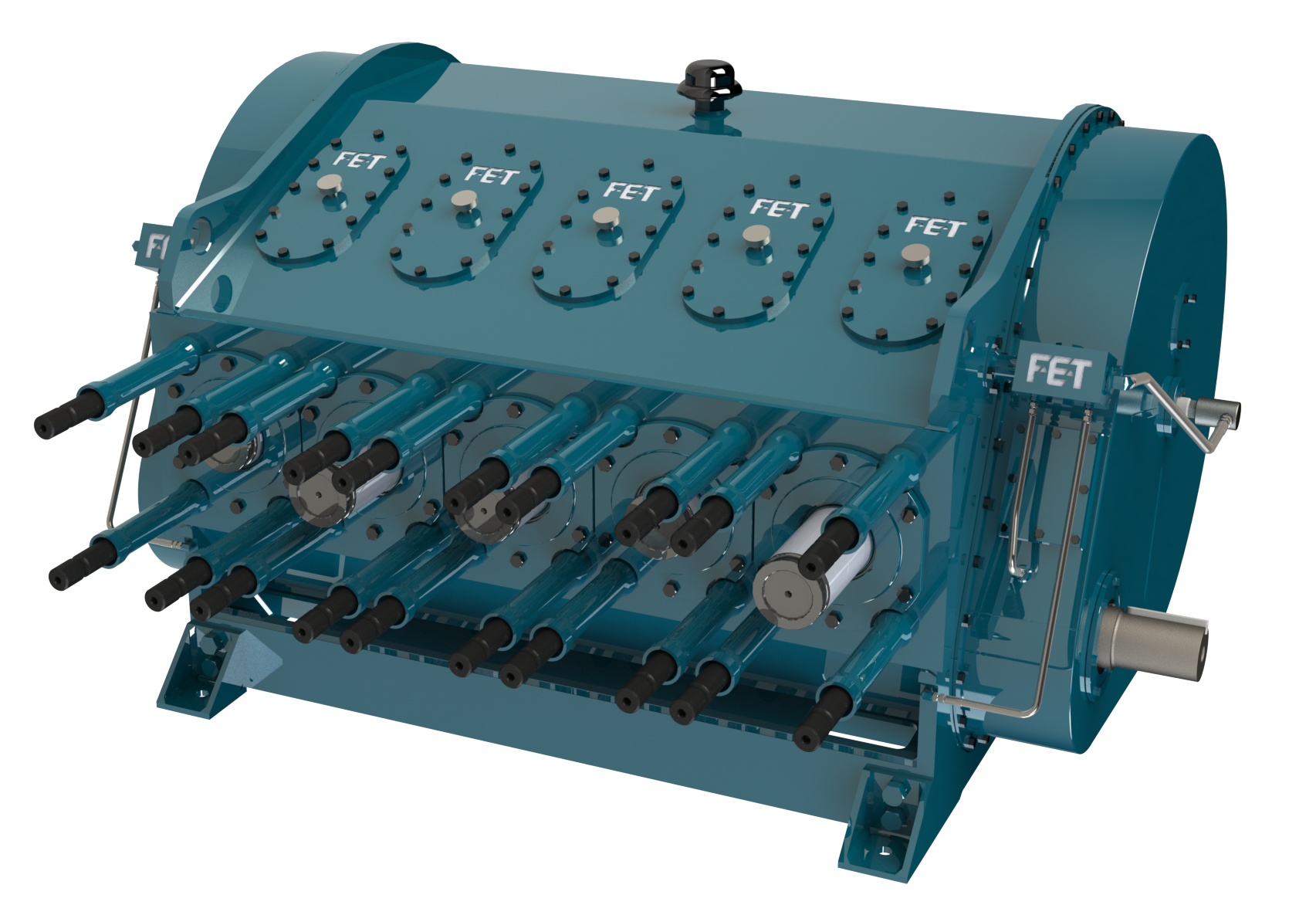

FXD3500 Power End: Built to Dominate the Toughest Jobs

3,500 BHP Quintuplex Frac Pump

When power, reliability, and field-proven performance matter most, the FXD3500 Power End from FET delivers. Engineered for high-output well stimulation, it is a trusted powerhouse across the industry with over 4 million cumulative pump hours, a testament to its durability and dependability.

Why Choose the FXD3500?

- Proven Reliability: Backed by more than 4 million operating hours in demanding frac environments.

- Confidence Guaranteed: Industry-leading two-year frame warranty for peace of mind.

- Precision Engineering: Designed to handle extreme rod loads and deliver consistent performance under pressure.

Key Specifications:

- Rod Load: 275,000 lb

- Stroke: 8″

- Maximum Input Power: 3,500 BHP

- Max RPM (Input/Output): 1950 / 307

- Gear Ratio: 6.353:1

- Center Distance: 12″

- Power End Weight: 13,512 lb

- Complete Pump Weight: 18,812 lb

Whether you’re expanding your fleet or upgrading for more demanding operations, the FXD3500 keeps your frac jobs running stronger, longer.

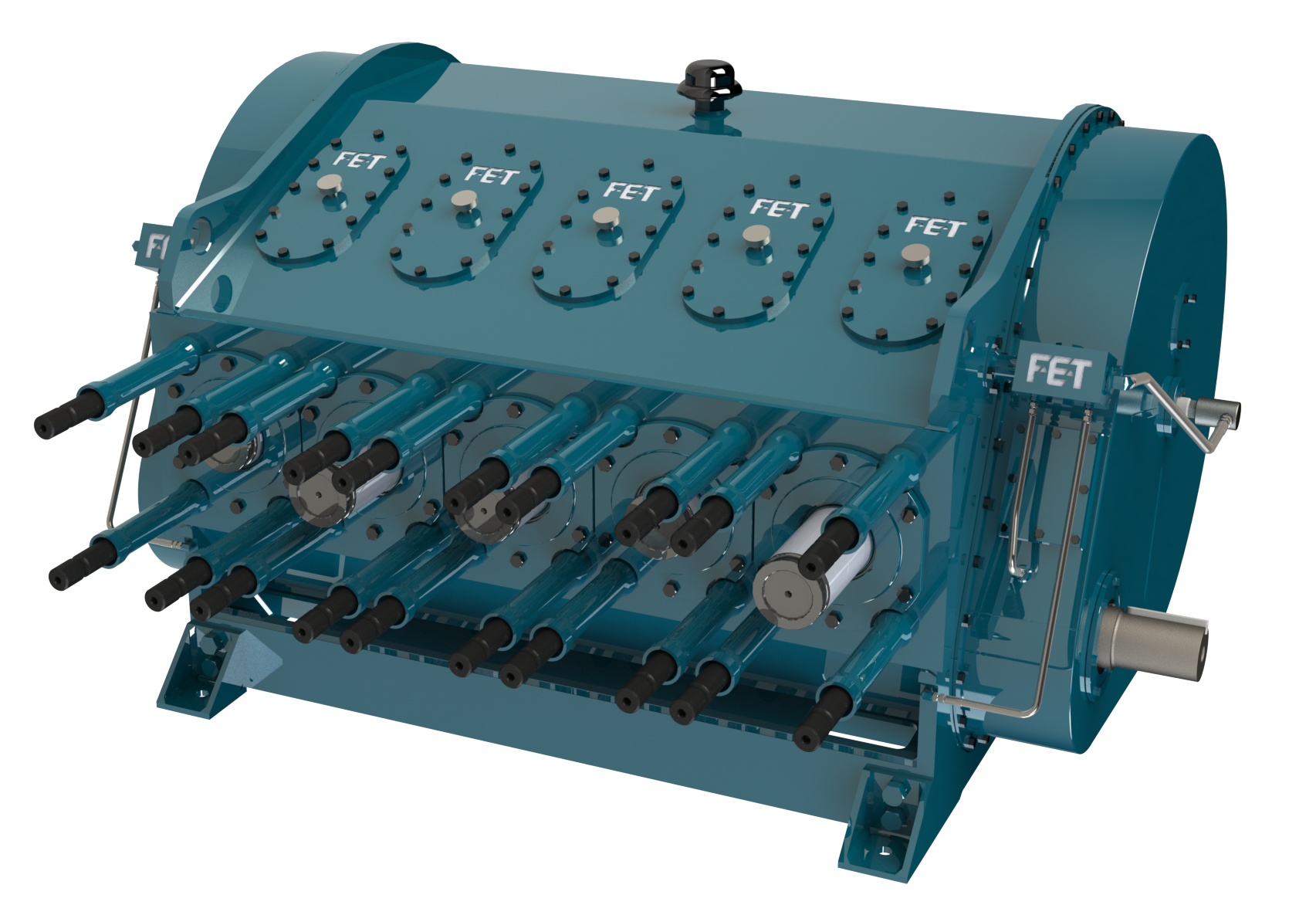

FXD3000 Power End: Proven Power for Precision Frac Operations

3,000 BHP Quintuplex Frac Pump

The FXD3000 Power End from FET is engineered to deliver consistent, high-performance output in demanding frac environments. With over 4 million cumulative pump hours and a two-year frame warranty, this field-proven workhorse offers unmatched reliability and long-term value.

What Sets the FXD3000 Apart?

- Trusted Performance: Proven in the field with millions of operating hours.

- Durability You Can Count On: Built to withstand high rod loads and intense operating conditions.

- Warranty Confidence: Industry-leading two-year frame warranty for peace of mind.

Technical Specifications:

- Rod Load: 240,000 lb

- Stroke: 8″

- Maximum Input Power: 3,000 BHP

- Max RPM (Input/Output): 1950 / 307

- Gear Ratio: 6.353:1

- Center Distance: 12″

- Power End Weight: 13,500 lb

- Complete Pump Weight: 18,800 lb

Whether you’re optimizing for efficiency or scaling for performance, the FXD3000 delivers the power, precision, and reliability your frac operations demand.

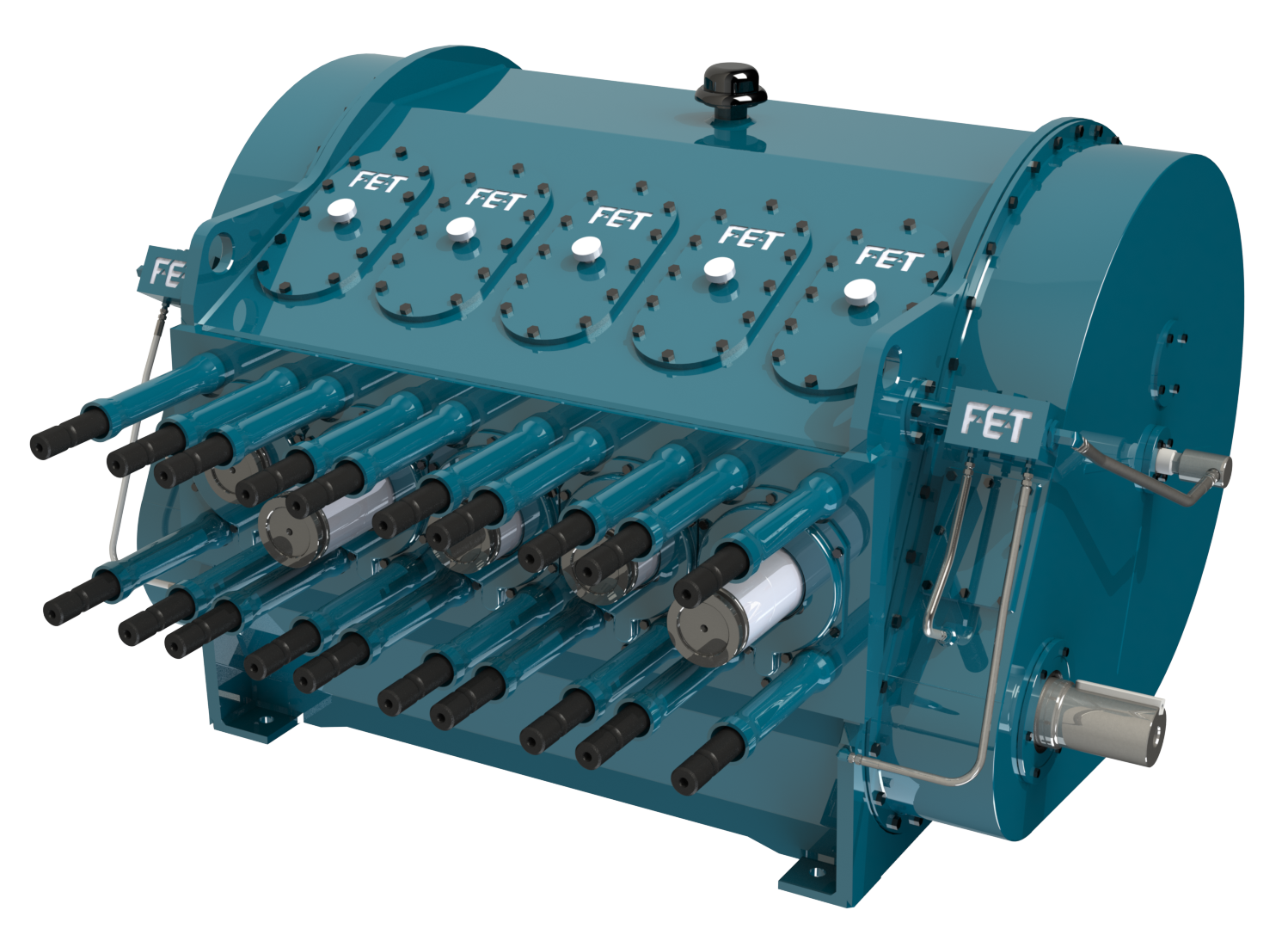

FXD2500 Power End: Proven Versatility with Powerful Results

2,500 BHP Quintuplex Frac Pump

FET’s FXD2500 Power End is a field-proven solution designed for performance, compatibility, and longevity. With a standard footprint and seamless integration into existing setups, it’s the ideal choice for operators looking to upgrade without compromise.

Why Choose the FXD2500?

- Reliable Performance: Engineered for superior pump life and consistent output in demanding frac conditions.

- Drop-In Compatibility: Easily replaces many 2,500 BHP power ends with no major modifications.

- Fluid End Flexibility: Compatible with most 52″ quintuplex fluid ends for streamlined operations.

Technical Specifications:

- Rod Load: 235,000 lb

- Stroke Length: 8″

- Maximum Input Power: 2,500 BHP

- Max RPM (Input/Output): 1950 / 307

- Gear Ratio: 6.353:1

- Center Distance: 10″

- Power End Weight: 12,600 lb

- Complete Pump Weight: 17,200 lb

Whether you’re replacing legacy equipment or expanding your fleet, the FXD2500 delivers dependable power and flexible integration to keep your frac operations running efficiently.

Frac Pump Repair & Refurbishment: OEM Precision. Industry-Wide Support.

FET delivers comprehensive frac pump repair services, whether your equipment is FET-built or from another manufacturer. Our expert technicians restore power ends to OEM specifications, ensuring optimal performance, extended equipment life, and minimized downtime.

What We Offer:

- Full-Service Power End Repair: We rebuild to original engineering standards for lasting reliability.

- Cross-Brand Expertise: We service both FET and competitor equipment with the same precision and care.

Service Locations:

Odessa, TX – Service Center 📞 +1 432 253-5202

Whether you’re maintaining a single unit or managing a full fleet, FET’s repair services keep your frac operations running strong.