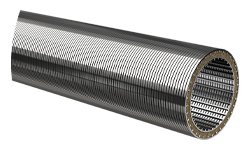

proPACK®: Prepacked Rod Based Wire-Wrapped Screen

FET Variperm’s proPACK Prepacked Rod Based Screens are manufactured and installed as a self-supported concentric assembly with no base pipe.

FEATURES & BENEFITS

- Diameters from 2” Pipe Size to 18” Pipe Size

- 0.250” – 1.00” radial pack

- Double re-sieved well rounded silica sand or carbo ceramic pack media

- Slot size selected based on filter pack media sizing

- 12-20, 16-30, 20-40 prepack media

- Corrosion-resistant stainless steel (304L or 316L)

- High flow rate with low-pressure drop

- Erosion resistant

APPLICATIONS

- Fine aquifer sands require filter media to achieve sand control

- Alternative to gravel packing

- High-rate water source wells

- De-watering wells

- Vertical and deviated water wells

- Remedial screen completions

Contact our sand control experts to learn how we can unlock the potential of your reservoir at [email protected].