Water Well & De-Watering Screens

Variperm is a trusted leader in the design and manufacture of high-performance water well screens and filtration systems for Water Well and De-Watering applications. With decades of experience and a commitment to innovation, we provide engineered solutions that meet the complex demands of groundwater extraction.

Our products are designed to perform in the most challenging conditions, ensuring long-term reliability, efficiency, and protection of valuable water resources. Whether you’re developing a municipal water supply, de-watering at a mine site, managing an industrial process, or monitoring environmental conditions, Variperm delivers the quality and performance you need.

Why Choose Variperm?

- Custom Engineered Solutions.

- Every well is different. That’s why we offer tailored designs based on your geological data, flow requirements, and installation method. Our team works closely with engineers, drillers, and project managers to ensure optimal performance and longevity.

- Rapid Turnaround. A large diameter well completion including washdown valve, screens, k-packers and accessories can be manufactured and ready to ship within a few days.

- With full control over our manufacturing processes, we can quickly adapt to design changes and meet tight project deadlines. Our in-house capabilities allow us to maintain quality while delivering on time.

- Unmatched customer service from highly knowledgeable, technical, friendly staff.

- From initial consultation to post-installation support, our team is dedicated to your success. We serve clients of all sizes with the same level of professionalism and care.

Optimized for Groundwater Performance

Variperm stainless steel water well screens are engineered to protect and enhance the performance of your well. With in depth knowledge surrounding reservoir characteristics and perm-porosity-consolidation-fines, Variperm is able to determine the exact sand control completion to deliver/construct the most efficient well with optimized rates and draw down characteristics.

Our Process:

- Step 1- Review well plan stick diagram to understand wellbore geometries, depths, geological zones, etc. Ideally this review is with the hydrogeologist as well as the drilling company to balance requests of the hydrogeologist with operations and drilling limits.

- Step 2- Complete particle size analysis and/or review particle size analysis provided to characterize sand which needs to be retained.

- Step 3- Design optimum screen and provide an engineering drawing with all dimensions and details specifically of the screen to the customer for approval.

- Step 4- Review installation plan and which type of rig will be installing the screen. Determine what additional accessory equipment will be required, such as specific K-Packers, and Wash Down Valve, Centralizers, Well Caps, etc.

- Step 5- Provide detailed engineering drawing of the full completion with all dimensions and details for customer to review and approve.

- Step 6- Manufacture full completion in-house with full control over quality and deliverability.

- Step 7- Ship direct from manufacturing to well site, and if requested an F-E-T Variperm Service Tech can support the installation and provide equipment to prepare the well and ensure the installation goes to plan. Service Tech works directly with rig personnel to provide all handling equipment which will work with the particular rig for safe and efficient handling.

- Step 8- Calgary sales/operations and engineering staff are available at any time during the installation to address issues such as making decisions to pull the liner and inspect if necessary, or advise on values for max compression or tension, or circ rates etc.

- Step 9- Follow up with customer periodically after the installation to understand how the well is performing and support in any way possible to ensure clients’ needs are met.

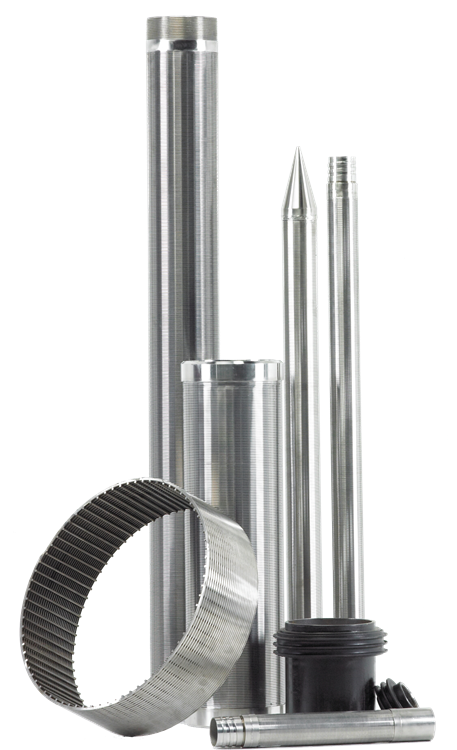

Our Water Well Screen Products

All Welded Wire Wrapped Screens

Well Screens are commonly manufactured using high-grade 304L and 316L stainless steel, known for their corrosion resistance and mechanical strength. For specific high corrosion applications, we also offer screens in Inconel, Duplex, and Super Duplex. Economical versions of standard screens are available and carbon steel screen completions are available.

Screens are suitable for use in all rotary, dual rotary, sonic, and hammer drill applications. Variperm Water Well Screens are all rated for various bury depths based on their rib and wrap wire combination and O.D. If a screen is required to be buried beyond its collapse rating depth, then the screen can be wrapped on base pipe.

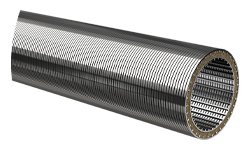

Pre-Pack Screens

Pre-packed screens are an alternative to a full traditional gravel pack. They are cost-effective, erosion-resistant, and provide optimized sand control for fine sand where the D50 is < 0.004”

These assemblies consist of an inner and outer screen jacket with a pre-installed filter pack, reducing installation time, and provide a high open area I.D for well development. Pre-Packed screens can provide a large diameter highly permeable filtration system that can provide 1,000 darcies of permeability and induce minimal skin.

For added strength, prepacks can be manufactured on perforated base pipe which increases bury depth potential and also provides more robustness to manage ground shifting or loading scenarios which would damage rod-based screens.

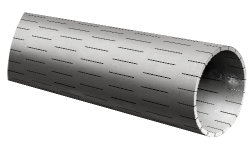

Slotted Liners

Axially slotted liners are a proven robust completion which are commonly used for HZ De-Watering wells as long as 2,000mMD. It has a high axial installation loading capacity, slim O.D. and can serve the function of hole consolidation or for solids control.