Reliable Protection for Downhole Cables — Even in the Harshest Environments

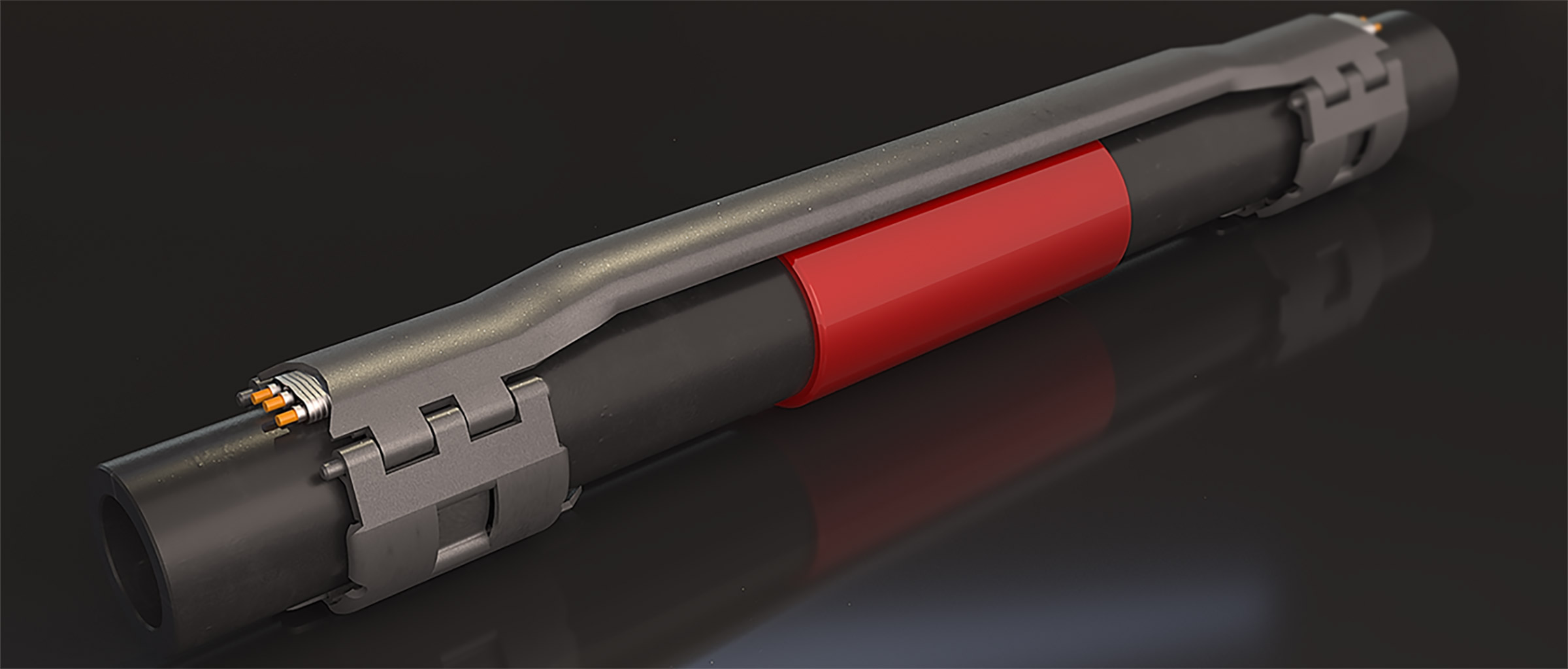

Downhole cables are especially vulnerable during installation and retrieval. FET’s cross-coupling protectors safeguard virtually any configuration of control lines, electric submersible pump (ESP) cables, umbilical lines, or encapsulated bundles within the wellbore.

Each protector features a robust channel that shields cables as they transition across the coupling, minimizing the risk of damage during completion operations. The compressive fit design accommodates both oversized and undersized tubing per API specifications, ensuring a secure grip on cables and lines.

Built for Tough Conditions: Super 25 Cross-Coupling Protectors

For wells exposed to aggressive environments, our Super 25 cross-coupling protectors offer the same dependable functionality as our standard models with the added advantage of exceptional corrosion resistance. Whether you’re operating in offshore, subsea, or high-angle wells, installation is fast and efficient using air-driven hydraulic tools.

These protectors are part of FET’s Cannon Services product line and the broader Multilift™ Solutions catalog.

Key Benefits

Standard Configuration:

- Prevents costly damage to cables and capillaries during installation and retrieval

- Highly reusable—ideal for reducing costs during well workovers

- Performs reliably in complex offshore and subsea well designs

- Quick installation reduces workover time and expenses

——-

Super 25 Configuration:

- Superior resistance to corrosion from acids, chlorides, and harsh wellbore conditions

- Excellent protection against chloride stress corrosion cracking and crevice corrosion

Features

Standard Configuration:

- Interchangeable designs for tubing with OD from 2″ to 13.75″ +

- Multiple channel options for multi-line configurations

- Suitable for high-angle and deviated wells

- Custom configurations available

- Options for corrosion-resistant alloys and specialty steels

——-

Super 25 Configuration:

- Exceptional resistance to uniform corrosion, pitting, and stress cracking

- Designed for long-term durability in corrosive environments

Applications

Standard Configuration:

- Artificial lift systems

- Permanent downhole gauges

- Intelligent well systems

- Fiber optic installations

- Safety valves

- Geophones

——-

Super 25 Configuration:

- Artificial lift

- Gas lift

- Intelligent wells

- Chemical injection systems