Hub-Style Connections

Over the past decade, well intensities including pumping hours, pressures, rates, and the chemicals / produced water within the frac media have drastically increased. Consequently, one negative effect of today’s harsh pumping conditions is that conventional hammer unions no longer provide a safe or reliable pressure connection. Cracks due to over-fatigue, leaking connections because of excessive vibration, and catastrophically failed connections as a result of iron misalignment are causing both safety hazards and non-productive time that have service companies demanding a more robust, reliable connection. The hub-style connector is a vastly superior option, as it offers a significantly stronger connection during extreme pumping conditions and a more user-friendly interface for field crews.

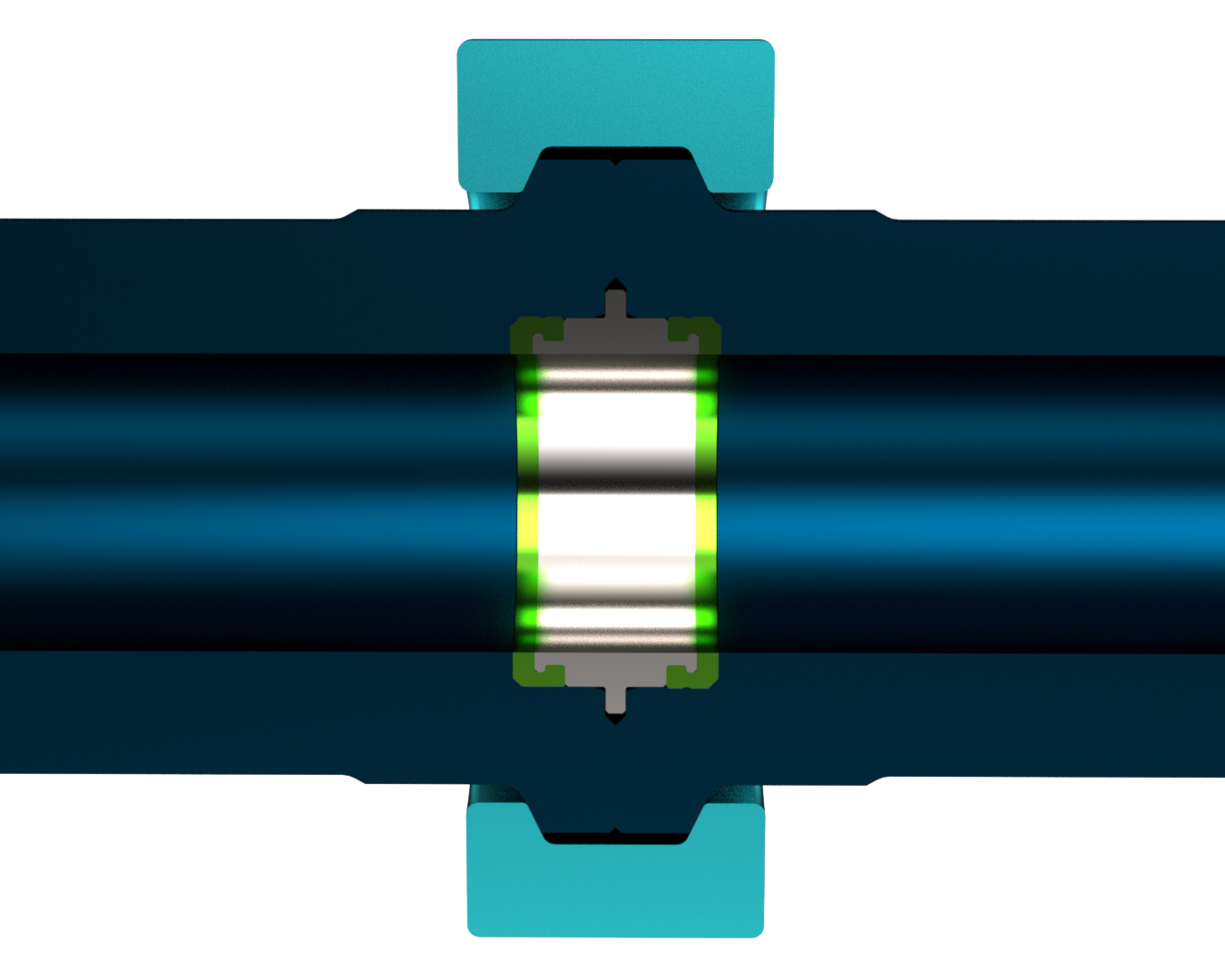

DuraLock Seal Technology

The DuraLock sealing technology offers our customers several key operational advantages over standard metal-to-metal gaskets including:

- Dual-elastomer design provides improved reliability by mitigating leaks due to grit and contaminants

- High-strength, corrosion-resistant seal carrier material promotes re-usability which reduces operating costs

- Pressure-energized seals assure joint integrity even at extreme pressures and exposure to aggressive chemicals

- Streamlined flow bore with zero obstruction

- Simplified iron alignment with recessed seal assembly design

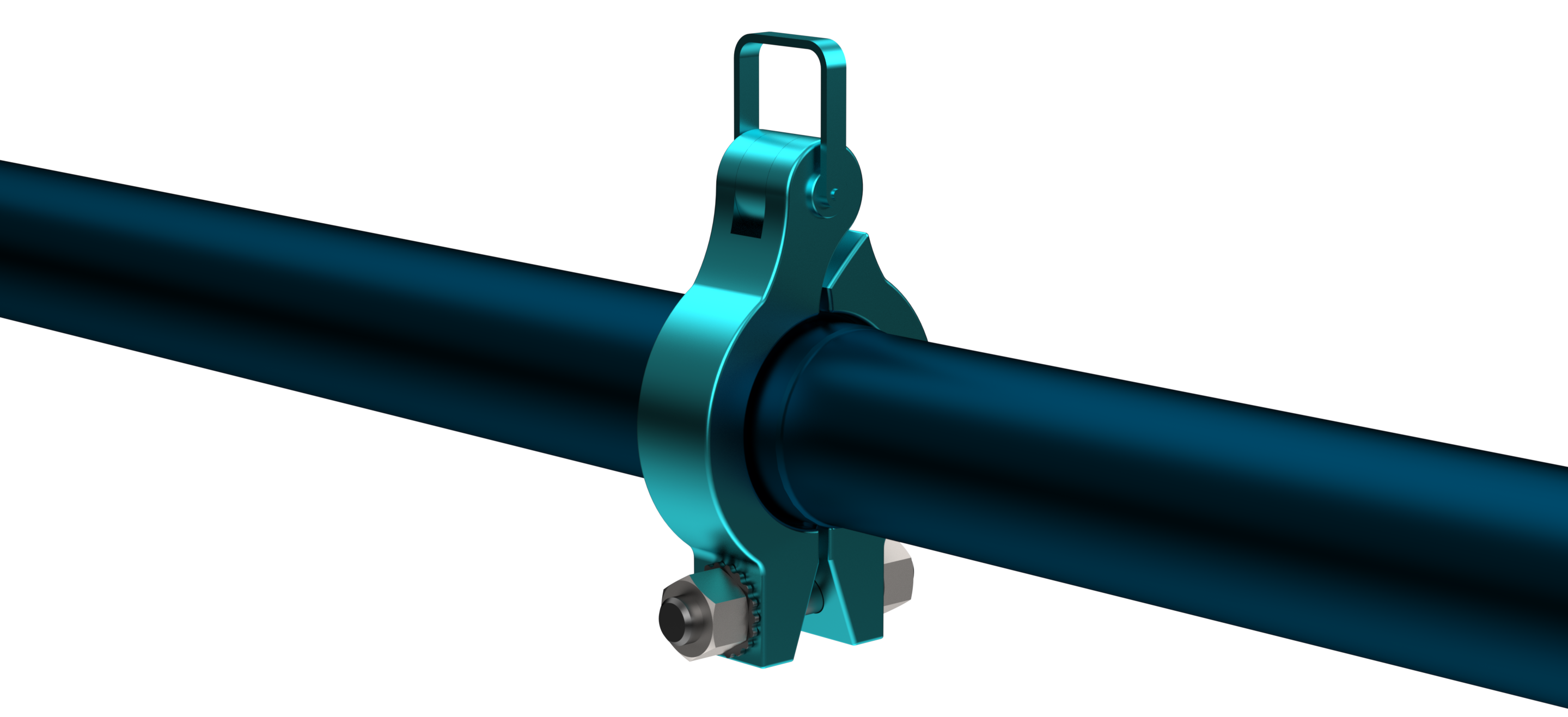

DuraClamp Single-Bolt Connector

Superior efficiency, improved reliability, and increased safety are key metrics that our customers demand with their pressure pumping equipment. The DuraClamp single-bolt connector is a unique design, which provides:

- Safer and easier installation than any other high-pressure iron connector in the industry

- Significantly faster make-up and breakdown processes minimize maintenance downtime

- Forged construction provides superior integrity

- 360° orientation allows the clamp to be arranged around obstacles

- Up to 80% lighter and significantly smaller than a comparable ANSI or API flange

- 75% less components to manage than a standard clamp connector

- Greater vibration fatigue resistance compared to traditional hammer union alternatives