The Serpent Series™, Flexible Hose Solution

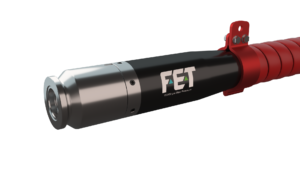

Operators can trust in FET’s Serpent Series™ flexible hose as the ultimate solution to replacing traditional iron used to transport pressurized fluids from the pumps to the well.

Flexible hose solutions made for real-world operations.

The Serpent Series™ patented flexible hose technology is a reliable solution for different areas of any pad layout. Our small-bore hoses provide a connection method from the pumps to the frac manifold, while our large-bore hoses can be used to connect the frac manifold to the well or zipper manifold. In both applications, we are able to provide operators with streamlined operations, improved safety, and reduced non-productive time that is typically incurred when utilizing traditional iron.

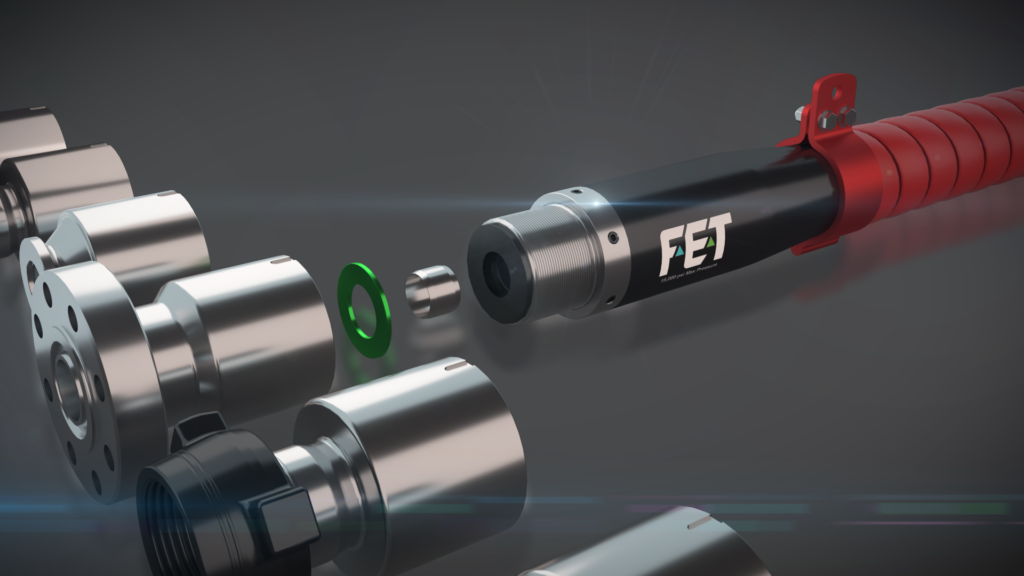

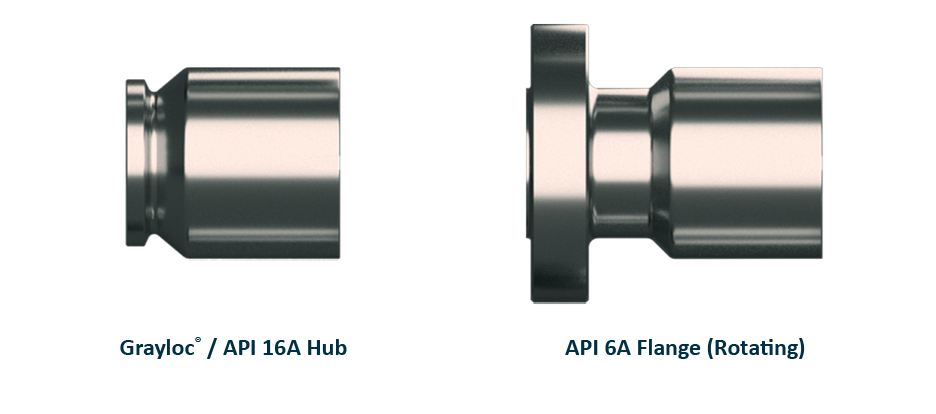

The FET Serpent Series™ flexible hose solutions are uniquely designed with our patent-pending modular end connections. This exclusive feature is beneficial to the operators, as it offers them the flexibility to change the end connection type to suit their rig up requirements. More importantly, the modular end provides the capability of replacing the end connection, in the event of a failure due to a fatigue crack, corrosion, or erosion. If utilizing hoses from other manufacturers, they would require a full hose replacement when end fitting issues arise. The FET Serpent Series™ is the only high-pressure frac hose equipped with replaceable modular ends fittings, which ultimately provides a significant reduction in total cost of ownership.

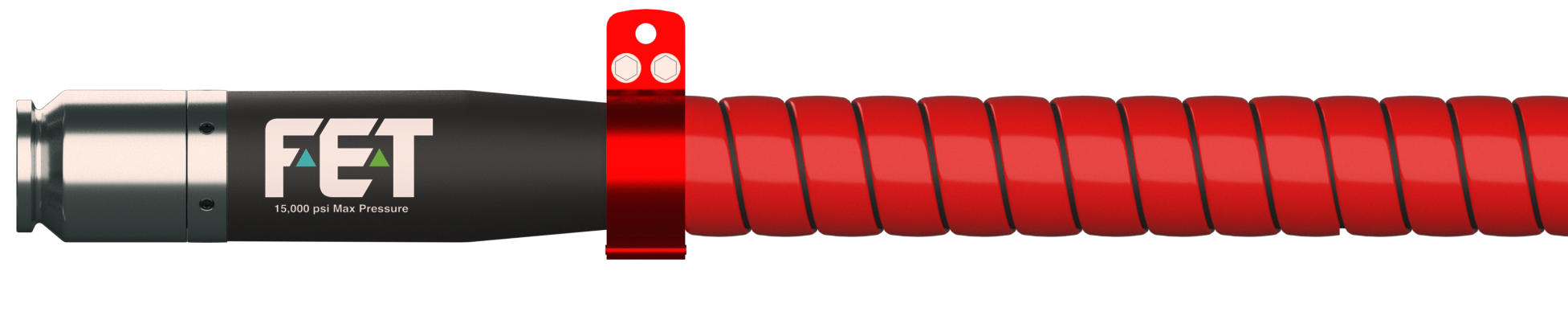

Engineered to improve your operations, the Serpent Series™ delivers a superior solution when upgrading your rig up from traditional treating iron.

- 100% manufactured in the USA means operators can count on premium quality and timely delivery.

- Available in 15K PSI Max Working Pressure.

- Patent-pending modular ends allow for easy change out or replacement of end connections.

- Unique, multi-color interior wear liner offers a simple visual indicator of hose condition.

- Single-strand wire construction provides operational advantages on the minimum bend radius and enables single-point lifting capabilities without the potential of damaging the hose.

Modular connections for unmatched end-fitting change capabilities.

Technical Data

| Hose Series | Hose ID (in) | Working Pressure (psi) | Max Rate (bbl/min) | Mininum Bend Radius - MBR (In Service) | End Connection Options |

|---|---|---|---|---|---|

| Viper | 2.5 | 15,000 | 18.2 | 30" | DuraLock / API 16A Hubs, Hammer Unions |

| Python | 5.0 | 15,000 | 120.0 | 48" | API 6A Rotating Flange |

| * 200’ max length; additional end connection options can be applied per customer request |

Contact our team for more information about upgrading your operations with the Serpent Series™ at [email protected].