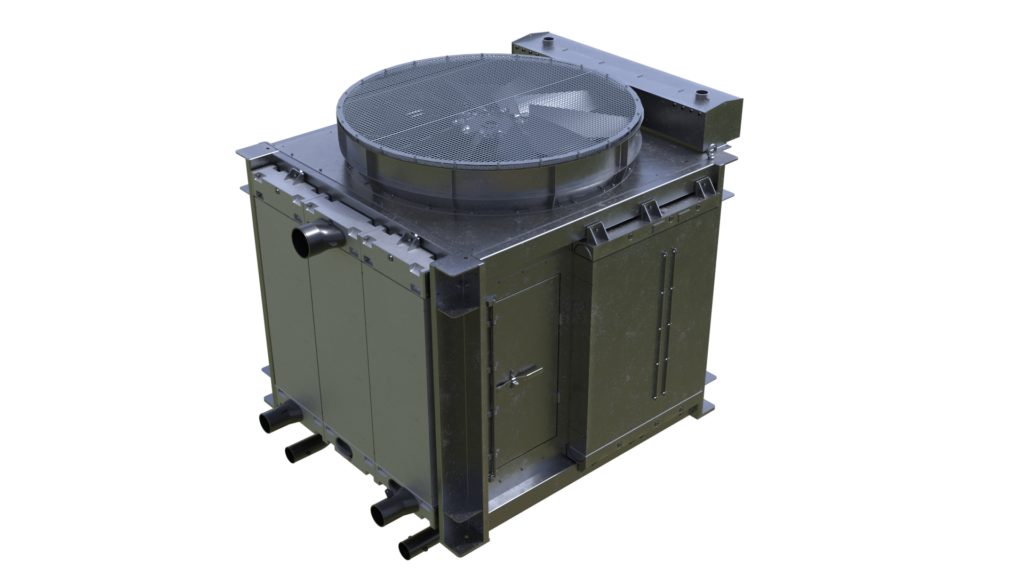

Modular Core System

At FET’s Global Heat Transfer (GHT), we design modular cores that enhance operational capabilities without compromising the performance. Our smaller cores allow for customized configurations based on specific applications.

Unlock Peak Performance

GHT’s modular cores combine industry-leading heat transfer efficiency with streamlined installation, reducing your total cost of ownership and minimizing footprint and weight.

BENEFITS

OPTIMIZING COOLANT FLOW

Efficient Coolers: Placing coolers in parallel significantly reduces resistance, enhancing coolant flow rates and heat rejection.

INNOVATIVE FOULING REDUCTION

Specialized External Fins: Prevent fouling and reduce static pressures, making fan usage more efficient.

COST OF OWNERSHIP

Reduced Inventory: Consolidates multiple coolers into a single standard part number, simplifying stock management and reducing costs.

ENGINEERED FOR PERFORMANCE

Built for Endurance: Operates to specifications even under maximum ambient conditions and fouling.

BUILT TO LAST

Extended Cooler Life: Features a mounting system with three degrees of freedom, minimizing mechanical reactionary forces.

DESIGN VERSATILITY

Adaptable to Any Engine: Fit seamlessly into any engine cooling application.

COST-EFFECTIVE MAINTENANCE

Quick Replacements: Compact size allows faster individual cooler changes, minimizing downtime and maximizing productivity.

SERVICEABILITY BENEFITS

Traditional horizontal radiators require extensive cleaning, which can take up to 40 hours. This process involves draining the radiator, removing it from the trailer, disassembling it, and power washing each section separately. After cleaning, the sections must be reassembled, reinstalled on the trailer, and refilled, which is time-consuming and labor-intensive.

In contrast, GHT radiators feature an innovative design that allows them to be pressure washed from the outside in under an hour without needing to be removed from the trailer. This quick and easy cleaning process significantly reduces downtime and maintenance costs, providing a substantial improvement over traditional horizontal radiators.

Additionally, our modular core allows users to isolate each cooler independently via manually actuated isolation valves. Combined with each cooler’s small size and weight, this feature enables users to drain and replace individual coolers without impacting the entire circuit. This minimizes downtime and maximizes productivity, making maintenance more efficient and cost-effective.

Modular Core Features & Benefits

- A Patented Isolation System allows the removal and replacement of cores in the field without draining the radiator.

- Integrated Valve enables isolation or removal and replacement of an individual cooler on the job site.

- Easy Removal and Replacement of cores facilitates offsite cleaning without shutting down operations.

- Interchangeable Cores simplify inventory management and field swaps.

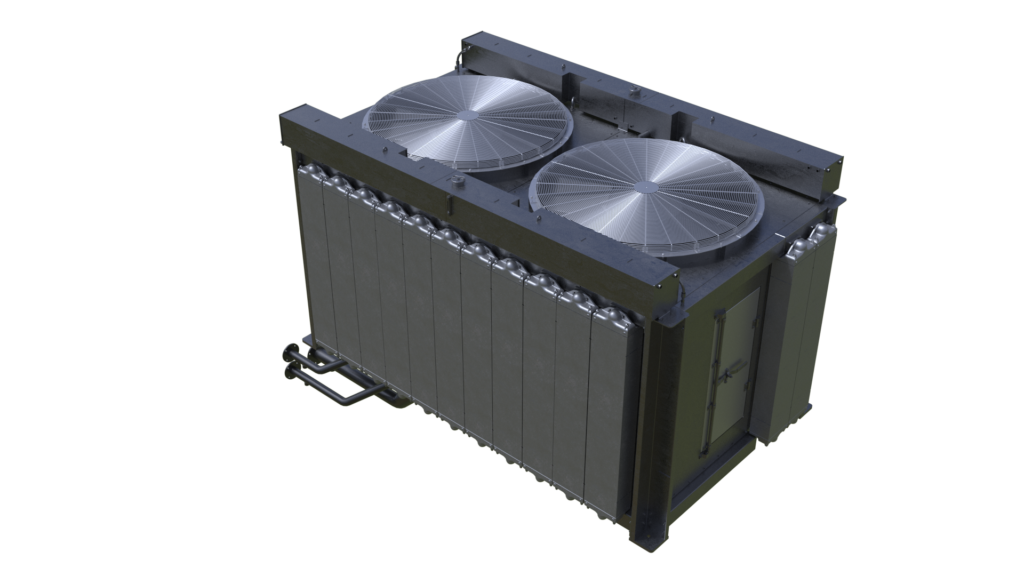

Introducing Powertron™ — Built for Excellence

At GHT, our passion for engineering drives us to create products that lead the way in performance, reliability, and innovation. The Powertron is a testament to this commitment, showcasing cutting-edge design and functionality.

Crafted to excel in natural gas-driven applications, the Powertron handles heat rejection demands that far exceed those of traditional diesel systems. Its advanced modular core technology ensures peak efficiency an delivers unmatched durability and adaptability in even the most demanding environments.

Building on the proven legacy of the Jumbotron, the Powertron embodies the next level of engineering innovation. When you need a solution that’s as robust as it is reliable, the Powertron is the ultimate choice.

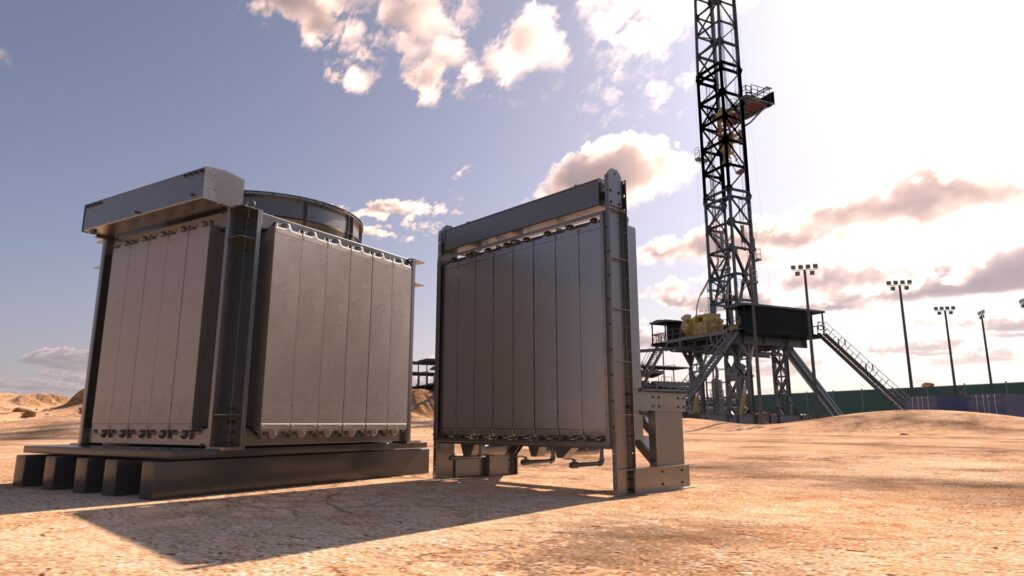

Jumbotron™ MC — Next-Level Cooling Technology

The Jumbotron MC, an evolution of GHT’s renowned Jumbotron, is engineered to deliver unmatched performance across diverse environments—from the icy extremes of the Canadian Arctic to the relentless heat of Texas. With modular core technology at its heart, the Jumbotron MC sets the standard for reliability in dual-fuel and diesel-driven applications.

Key features include:

- Innovative Belleville Washer Mounts: Allow modular cores to move with three degrees of freedom, reducing thermal stresses and extending cooler lifespan.

- Patented Airflow Improvement Kit: Enhances airflow by up to 20%, optimizing cooling capacity and minimizing noise.

- Cooler Isolation Mounts: Patented design enables charge air coolers to float within the steel frame, reducing wear and tear.

- Hydraulic Installation Kit: Simplifies setup with an upgraded motor boasting a 42,500-hour lifespan, anti-cavitation and flushing valves, and pre-installed hoses for convenience.

- Bottom-Mounted Oil Cooler Ports: Ensure faster, easier, and safer maintenance.

- Flexible Frame Design: Modular coolers can be removed individually without disassembling the entire unit—offering unparalleled efficiency.

Rated for up to 140°F (60°C) ambient conditions, the Jumbotron MC provides dependable cooling for high-demand applications like power generation and fracking. Experience innovation and durability redefined with the Jumbotron MC.

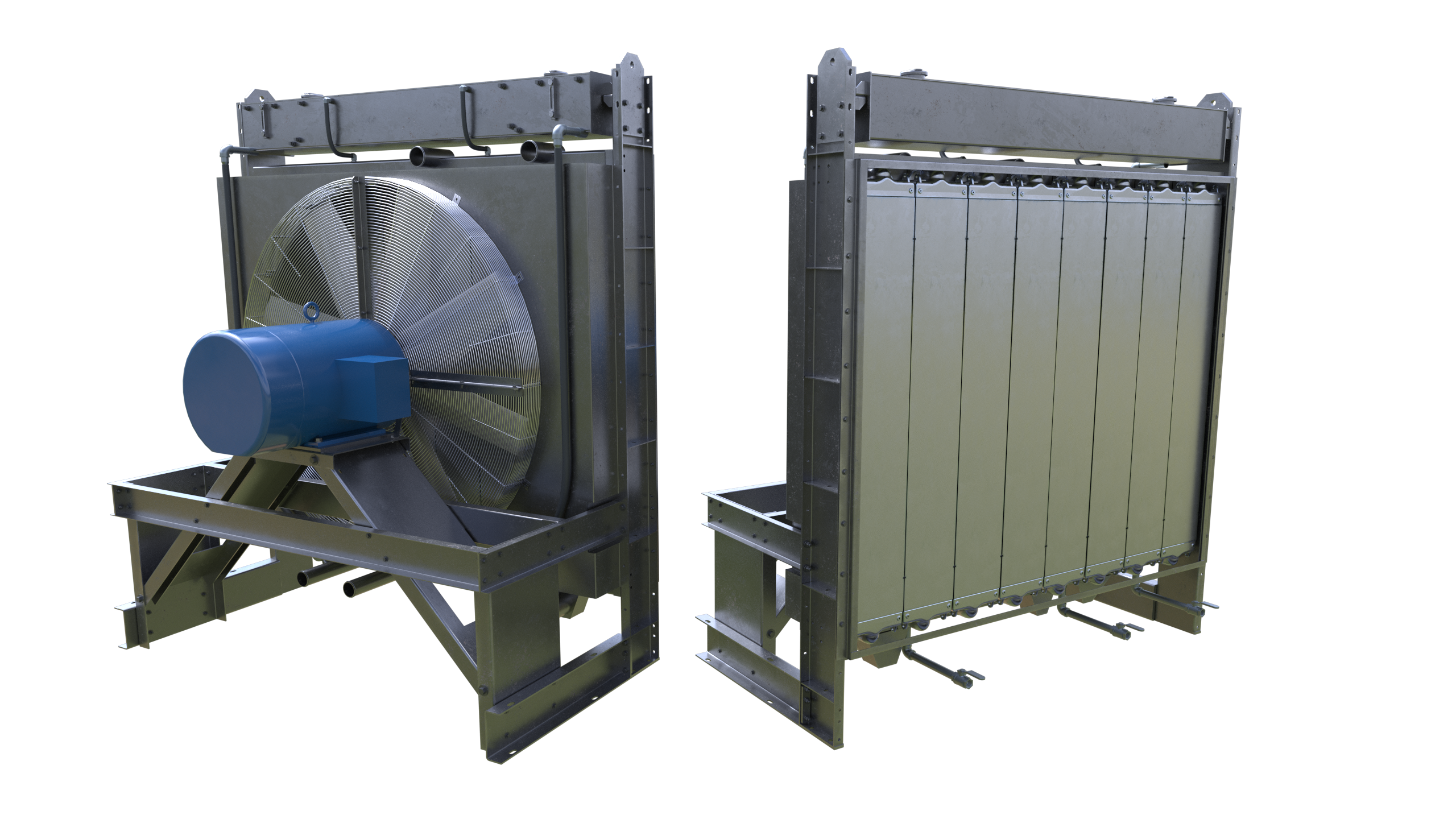

Vertical Radiators — Built for Performance and Efficiency

At GHT, we engineer our vertical radiators with serviceability and reliability in mind. Designed for effortless maintenance, these units allow cleaning directly onsite or in the shop without removing or disconnecting components, ensuring seamless operation and reduced downtime.

Innovative Cooling Technology — Integrated with advanced heat transfer solutions, GHT’s vertical radiators excel under extreme conditions, minimizing overheating risks and extending operational lifespan. Our commitment to cutting-edge design guarantees optimal performance, reducing maintenance costs, and enhancing productivity across industries.

DRIVE OPTIONS TAILORD TO YOUR NEEDS

Remote Drive Options —

- Customization: Select from a variety of VFD-compatible electric motors with area classifications to suit your efficiency, power-saving, or space-saving goals.

- Hydraulic Motors & OHLA Options: Customizable hydraulic motors for diverse operational requirements.

- Precision Structure: Constructed to meet the rigorous demands of the oil and gas industry.

Direct Drive Options —

- On-Engine Sucker or Blower Fans: Providing radiator packages with these fan options for versatile functionality.

- Jackshaft Units: Complete fan drive systems, including the stub shaft, for robust and efficient operations

Why GHT Vertical Radiators? With a focus on reliability, cost-effectiveness, and efficiency, GHT’s Vertical Radiators are the trusted choice for industries requiring superior cooling technology and reduced operational downtime.

Engineering Excellence

At GHT, we excel in creating innovative engineering solutions that prioritize weight, durability, and heat transfer optimization. With a commitment to quality, our rigorous feasibility tests guarantee flawless designs before production begins. Discover the expertise and innovation that define GHT.