The Jumbotron: A Cooling Marvel

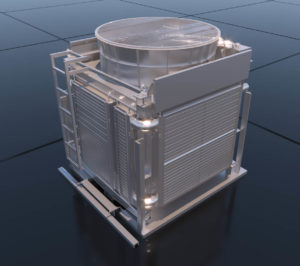

Since its introduction in 2009 by GHT (Forum Energy Technologies, Inc.), the Jumbotron has made waves in the industry. These cooling systems have successfully operated across diverse climates, from the Canadian Arctic to the sweltering heat of Texas. Over time, the Jumbotron has undergone five significant redesigns to enhance product quality and longevity.

Here are some key features of the Jumbotron:

- Efficient Mounting: The coolers are individually mounted outside a steel frame using four to eight bolts and isolator mounts. This design facilitates routine maintenance and repairs, improving operational efficiency.

- Reduced Cleaning Time: The Jumbotron significantly reduces annual cleaning efforts, saving operators over 106 hours annually.

- Impressive Airflow: Despite its slim wall thickness (only 6 inches), the Jumbotron can pull an impressive 25,000 CFM (100,000 CFM total) through each of its four sides. In comparison, traditional horizontal radiators often require up to 30 inches of thickness to achieve similar airflow.

- Innovative Core Design: The Jumbotron’s core design minimizes airflow resistance, leading to less core plugging in the field.

Core Types for Diverse Needs

At GHT, we recognize that different operating environments demand specific solutions. That’s why we offer a range of core types to address various concerns. Here are the core types we provide:

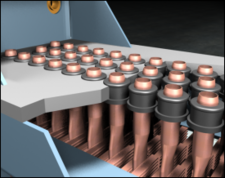

Rubber Grommetized & Removable Tube

BENEFITS:

- Absorbs vibration and thermal expansion with a rubber grommet.

- Easily remove and replace tubes for cleaning or in case of accidental damage.

- Field-repairable using simple hand tools.

- Ensures long-lasting durability.

- Comes with an impressive up to 4-year/25,000-hour warranty.

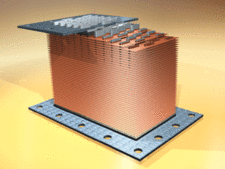

Aluminum Plate & Bar

BENEFITS:

- Lightweight and cost-effective.

- Ideal for Air-Air or Air-Oil cooling applications.

- The lightweight design can yield significant weight savings (up to 4,000 lbs.).

- Cores are rated up to 750psig and burst tested up to 2,000psig.

Industrial Bolt-On

BENEFITS:

- Highly efficient.

- Multiple fin configurations allow for compact, customized designs.

- Quick delivery and easy repairability.

- Cost-effective.

Cooler Options for the Right Fit

High-Pressure Coolers: A Breakthrough

GHT is the first aluminum cooler manufacturer to offer standard operating pressures of up to 750 psi. Leveraging cutting-edge technology, advanced materials, and precise processes, we provide standard and custom-built coolers capable of handling the most demanding applications. Our coolers boast burst pressures that exceed 2200 psi, ensuring robust performance in extreme conditions.

Fin & Tube Designs for Every Need

GHT’s commitment to innovation extends to our fin profiles and tube designs. Whether you require a compact heat exchanger or a cooler designed for dirty applications, we’ve got you covered. Our in-house CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) software positions us at the forefront of developing new fin technology in the industry.

Versatile Motor Options

At GHT, we understand that diverse applications demand flexibility. That’s why we offer a range of motor options for our standard and custom-built coolers. Whether you need electric motors (12/24V DC or AC), hydraulic, or pneumatic motors, we’ve got solutions tailored to your specific needs.

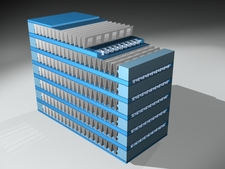

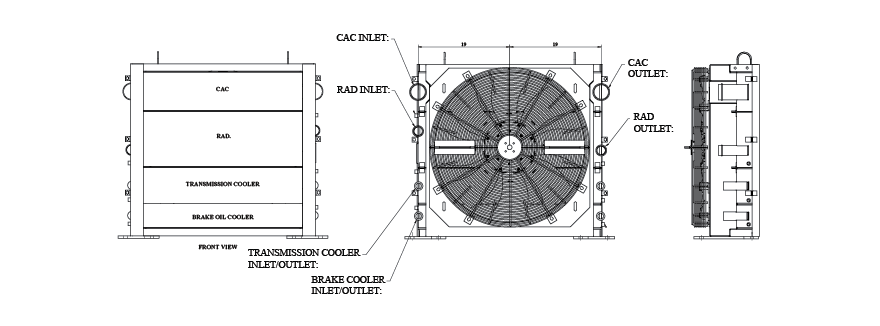

All-in-One Cooling System Design

Our innovative cooling system takes efficiency to new heights. We achieve a space-efficient design by integrating various coolers into a single package within a radiator. The key advantage? You’ll only need a centralized power source, streamlining installation and reducing overall equipment weight, which translates to long-term fuel cost savings for your operation.

Available Coolers:

- Transmission Cooler

- Hydraulic Cooler

- Brake Oil Cooler

- Compressor Oil Cooler

- Lube Oil Cooler

- Charged Air Cooler

Cooler Configurations: Versatility at Its Best

At GHT, we understand that cooling needs vary; one size doesn’t fit all. That’s why we offer a range of cooling system designs to cater to diverse requirements. Here are the options we provide:

Front-Back Designs: In this configuration, each cooler mounts behind the other one. The front cooler receives the coldest air first. It’s an efficient arrangement for specific applications.

Stacked Designs: Here, one cooler is stacked on top of another. The coldest air benefits both coolers, maximizing cooling efficiency.

Side-by-Side Designs: Coolers are positioned side by side and receive the coldest air simultaneously. It’s a straightforward yet effective setup.

Retro-Fit: We specialize in adapting existing designs to original specifications. If you have a specific cooler in mind, we can build it for you.

Combinations of all Four: Depending on cooling requirements and special requests, we may incorporate a mix of the above designs. Flexibility is key!

Dynamic Gas Blending (DGB) and Dual Fuel Compatibility

In today’s market, cost reduction and emissions compliance are critical. Enter DGB/Dual-Fuel technology, which allows operators to cut fuel costs significantly. However, not all cooling systems can meet this new operational standard.

At GHT, we’ve got you covered. Our radiators and cooling systems ensure optimal performance, even in ambient temperatures of up to 131ºF. Whether you’re blending gases or running dual fuel, trust GHT to deliver.

Core Designs for Specific Concerns

We offer a variety of cooler options backed by three innovative core designs:

Rubber Grommetized and Removable Tube:

- Absorbs vibration and thermal expansion.

- Easy tube removal and replacement for cleaning or repairs.

- Field-repairable with simple hand tools.

- Long-lasting durability.

Aluminum Plate & Bar:

- Lightweight and cost-effective.

- Excellent for Air-Air or Air-Oil Cooling.

- Designed to withstand pressures of over 2,000 psi.

Industrial Bolt-On:

- Highly efficient.

- Compact, customized designs with multiple fin configurations.

- Quick delivery and easy repairability.

- Cost-effective.

Jumbotron: Savings and Efficiency

Consider our Jumbotron system, which boasts a proven return of over 200% annual ROI compared to horizontal market options. It’s a wise investment that pays off.

Need a custom solution? No problem! GHT specializes in custom-designed cooling systems tailored to DGB/Dual Fuel systems. For more information, contact our cooling system experts at [email protected].

Compatible DGB / Dual Fuel Engines

CAT 3512E ATAAC 2500HP @ 1900RPM T4

CAT 3512E SCAC 2500HP @ 1900RPM T4

CUMMINS QSK50 2500 HP T4

Engineering Excellence

At GHT, we excel in engineering products that balance weight, durability, and heat transfer optimization. Our feasibility tests ensure flawless designs before production begins. Explore the world of cooling solutions with GHT’s Jumbotron—an all-in-one cooling marvel! For more details, refer to the GHT Jumbotron datasheet.