Splice & Gauge Protectors: Reliable Protection for Critical Downhole Connections

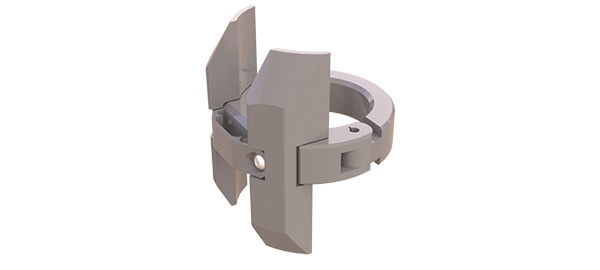

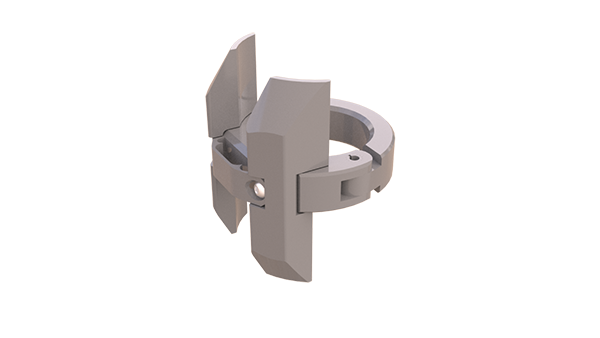

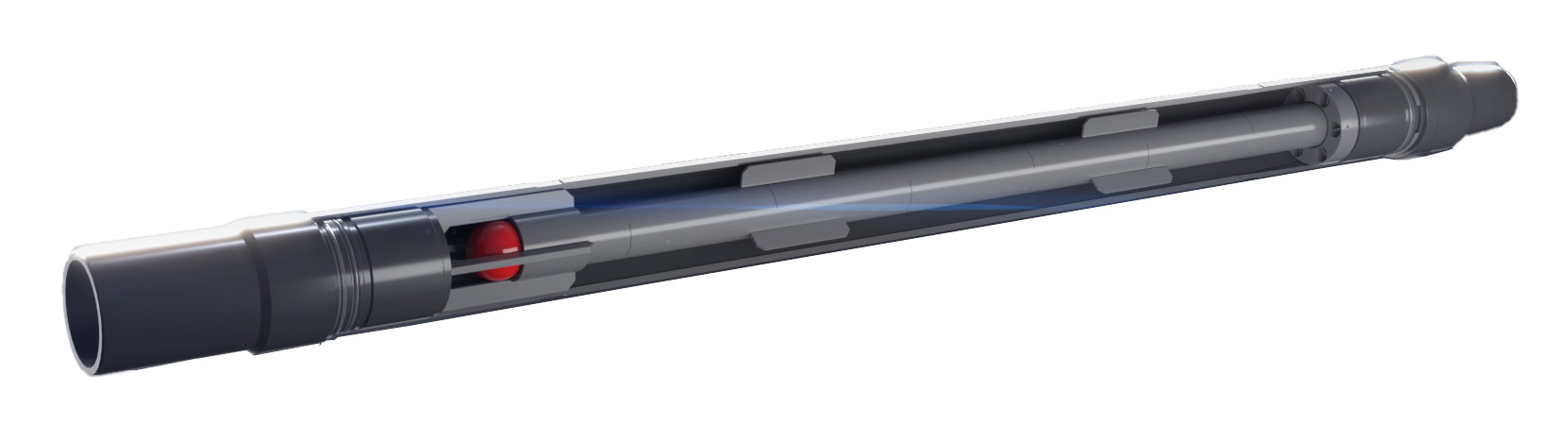

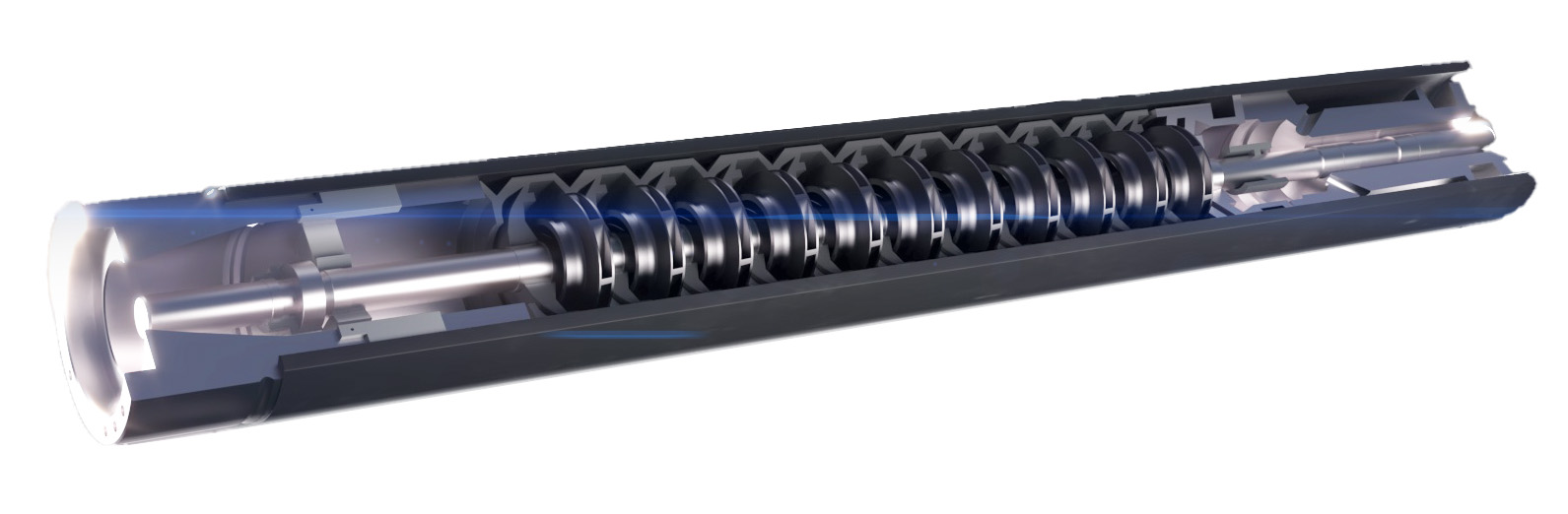

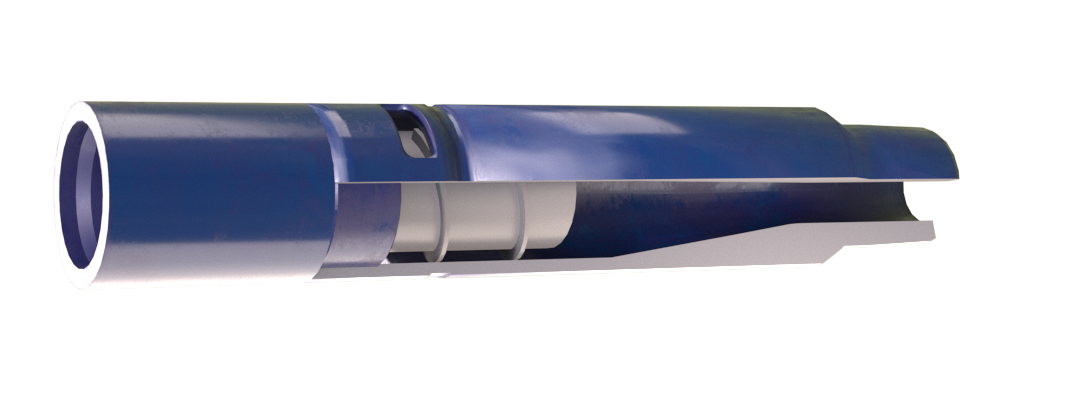

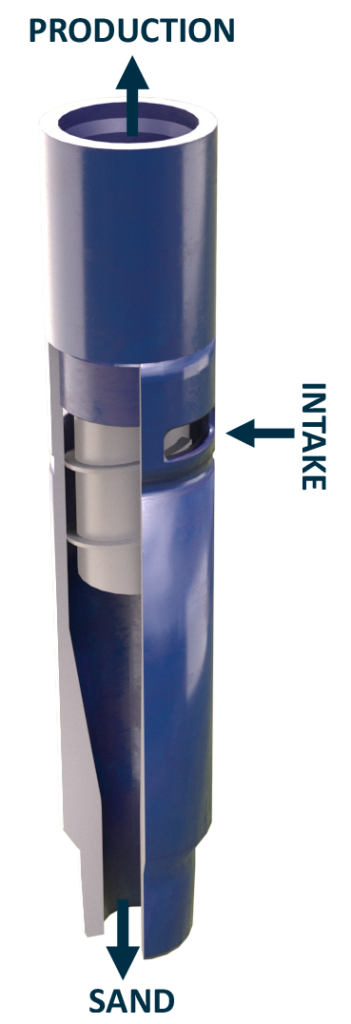

FET’s splice protectors, part of our trusted Cannon Services product line and MultiLift artificial lift solutions, are engineered to safeguard cable splices from mechanical stress during installation, retrieval, and long-term operation in the wellbore.

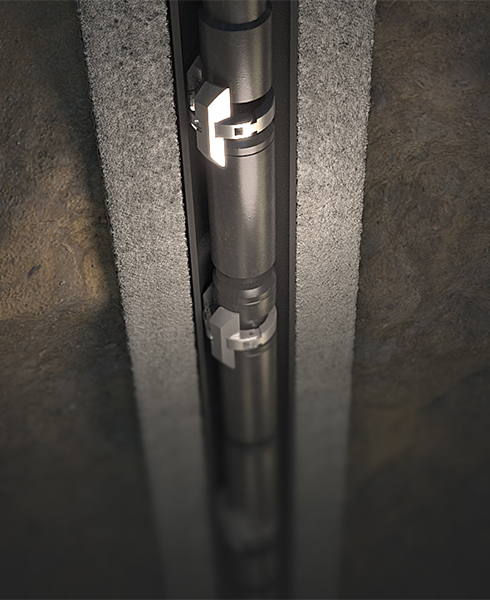

With a wide range of configurations and materials, we build our protectors to meet the demands of complex well designs, including high-angle and offshore/subsea environments.

Key Benefits

- Prevent costly damage to cable splices during installation and workovers, ensuring uninterrupted performance of ESPs, sensors, and other downhole systems.

- Our high-durability designs are reusable across multiple well cycles, helping operators cut costs on recompletions and reduce non-productive time.

- From deepwater to deviated wells, our protectors are built to perform in the most challenging environments with a fast, secure installation that minimizes rig time.

Key Features

- Flexible Fit: Interchangeable designs for tubing ODs from 2.375″ to 13.75″ +

- Versatile Configurations: Flat-to-flat, round-to-round, and flat-to-round splice compatibility

- Broad Compatibility: Supports TEC, hydraulic lines, fiber optics, and more

- Custom-Built: Tailored to your well’s specifications

- Deployment Options: Mid-joint or cross-coupling assemblies

- Material Choices: Available in corrosion-resistant alloys and specialty steels

- High-Angle Ready: Designed for complex well trajectories

Applications

- Electric Submersible Pump (ESP) cable splices

- Heater cable splices

- Downhole pressure/temperature transducer Y-blocks

- TEC and fiber optic splices

Protect your investment below the surface.

FET’s splice protectors deliver the durability, adaptability, and performance your operations demand well after well.