There are many times when there is a need to verify the cable. Some reasons include:

» when removing the cut cable, being unclear about its length,

» verification of the cable record book,

» checking a cable length in the yard or

» just being sure you have enough line to get to the bottom.

Whatever the reason, having a quick, easy, and accurate means of determining the cable length is invaluable. This technical bulletin outlines the formulae for accurately determining the length using only an ohm meter and access to both ends of the cable.

For best results, use a good quality meter with 5-digit resolution, and follow these steps:

- Short the meter test leads and record this resistance: RL (Ω).

- Measure end-to-end cable conductor resistance plus the test leads resistance: RM (Ω).

- Total cable conductor resistance is RT = (RM – RL) at shop temperature (Ω).

- Listed on the final inspection report supplied with cable is RK, which is the cable resistance /1000 ft. @ 68°F.

Calculate cable length:

L = (RT / RK) x (458 / (390 + T)) x 1000

L = Length of the cable in feet

-390°F is the inferred zero resistance temperature

T = Shop temperature at the cable location (°F)

Metric Formulae:

L = (RT / RK) x (254 / (234 + T)) x 1000

L = Length of the cable in meters

T = Shop temperature at the cable location (°C)

RK = is the resistance of the center conductor per km at 20°C

Example: 1-A-224-12/18-G (Sample Cable)

RL= 1.50 Ohms

RM= 64.65 Ohms

RT = 64.65 – 1.50 = 63.15 Ω

RK = 4.11 Ω/1000 ft.

T = 42°F

L = (RT / RK) x (458/(390+T) x (1000)

L = (63.15/4.11) x (458/(390+42)) x (1000)

L = 16,280 feet, length of the cable

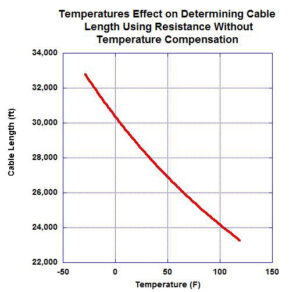

The component of the imperial formulae (458/(390+T)) is used to temperature compensate the resistance back to 68°F where “RK” was calculated. The cable length error could be very significant if the temperature compensation was not performed. The graph on the following page shows the error in cable length that could occur due to not temperature compensating. The example is a 7/32-in. mono-conductor, 25,860 ft. in length. Determining the length if temperature compensation was not accounted for would range from 23,000 ft. at 110°F in the summer heat to 33,000 ft. in northern winters. Clearly, the error is not insignificant.

“RK” can be found from three sources:

1) An average value of “RK” (DC Conductor Resistance) found on the cable spec sheet should only be used if the actual calculated values cannot be found.

2) Each Quality cable comes with a Quality Certificate which contains the actual value of “RK” as determined at the manufacturing plant.

3) When the cable is first purchased and installed, the resistance (Ri), length (Li), and temperature (Ti) should be recorded in the cable record book, and “r” should be calculated using the following formulae:

RK = (Ri / Li) x 458 / (390 + Ti) x 1000

Example:

Li = 25,100 ft Ri = 260.2 Ω Ti = 77°F

RK = (Ri / Li) x 458 /(390 + Ti) x 1000

RK = 10.1 Ω/kft (this is the value of “RK” that should be recorded in the cable record book)

Metric Formulae:

RK = (Ri / Li) x 254 / (234 + Ti) x 1000

Ti = T°C, Li = m, Ri = Ω, RK = Ω/km

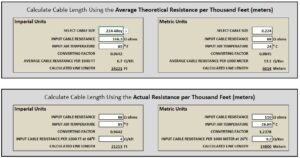

You can go online to the FET|Quality Wireline resources page to find two applications under “Cable Specifications & Calculators” that will be useful to you with your calculations:

1) The Unit Converter converts any engineering units desired.

2) The Cable Length calculator allows you to select the cable type and input the resistance and ambient temperature to calculate the cable length. For better accuracy, over-ride the cable type and directly input the value of “RK” as explained above.