From a cable manufacturer’s perspective, this technical bulletin intends to look at best practices on pressure work for longer cable life.

Many energy companies perform wireline operations when the well is “live” or the wellbore pressure exceeds the atmospheric pressure. There are several reasons for performing live operations, including

» lowering the cost of operations,

» reducing formation damage,

» minimizing lost production due to downtime and

» performing pump-down operations.

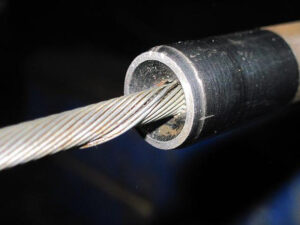

By design, armored lines (aka wirelines) have interstices between armor wires and armor layers, which you cannot pack off directly. A grease head and lubricator are employed to maintain well control during “live” operations. Before the rope socket is attached, the wireline passes through several closely fitting flow tubes (pictured below).

![]()

Viscous grease is injected into the assembly at pressures exceeding wellbore pressure and fills the space between the wireline and the inner diameter of the flow tubes. The grease packed in the tight annular space provides significant resistance to wellbore pressure by adhering to the surfaces of the cable and the flow tubes while permitting the wireline cable to travel into and out of the wellbore. Each subsequent flow tube creates a compounding pressure drop, so there is no residual pressure drop as the wireline exits the flow tube. Pressure is maintained higher than wellbore pressure with a grease pump. The tighter the annular space, the higher the force (pressure) required to displace the grease. This principle is the same for both braided wireline and slickline.

A pack-off is mounted at the top of the lubricator to seal the well in case of losing pressure control through the grease head. It should not be used as a line wiper because the packing rubbers are harder and can cause damage to the wireline. These devices also prevent the wireline from rotating, which causes the armor to loosen and may result in a birdcage below the pack-off. Additionally, wear on the pack-off rubbers can limit their ability to seal the wireline effectively if the flow tubes cannot hold back the wellbore pressure. In reality, many operators use the pack-off to wipe the line, specifically when the flow tubes are oversized, and pressure control with grease is difficult to maintain.

The argument for wiping the line is that the wireline equipment and well site stay clean, providing a better work area and more responsible environmental stewardship. More and more operators working offshore and in environmentally sensitive regions require line wipers. If you require or plan to use a line wiper, we highly suggest using one in addition to the pack-off. In other words, do not use the pack-off for this purpose.

You can purchase supplemental line wipers with softer rubber. A proper setup will allow the pressure on the line wiper to have more sensitive control than a pack-off to minimize the force on the wireline. Never use the line wiper to control pressure; their only use is to clean the line. However, the user should always be aware that there is the possibility of damaging the wireline when using a line wiper.

New Cables

New cables can be risky for pressure work because the cable is subjected to only a few hundred pounds of tension during manufacture, so there is essentially no torque in a new cable as delivered. When installed on a truck, the spooling tensions are significantly higher than during manufacturing. Because the cable is not free to rotate, it will develop significant torque and try to rotate to equalize this built-up torque and support the weight of the tool string when making the first field operations.

To illustrate the magnitude of this problem, consider a new 7/32-in. cable deployed in a straight 20,000-ft. well. The total rotations a new cable end would need to rotate to equalize the torque could be over 400. Until the cable is well “seasoned,” we recommend that flow tubes be on the high end of the industry standard (0.004 to 0.006 of an inch) to allow for line diameter and cable rotation changes. This “seasoning” is critical to the life of a wireline cable, and we recommend reviewing Technical Bulletin 2―New Cables: Understanding the Issues and Tips for Longevity, which discusses line speeds and operational practices for new cables.

Pressure work also slows the seasoning process by lubricating the cable and preventing grit and corrosion from forming in the armor’s spaces. This wellbore fluid and grit, combined with corrosion, helps prevent the cable from spinning, which is important in seasoning. Once seasoned, the lubrications from grease jobs are good for the cable. You will require a substantial amount of extra grease to fill the interstices between the armors the first time you use a cable for grease injection.

Always use new flow tubes on new cables. Used flow tubes may have wear, and it is not necessarily even around the diameter of the flow tube. This non-uniform wear can cause a high friction spot in the flow tubes and a non-uniform annulus between the flow tube and cable. These circumstances are not worth risking cable damage, particularly on a newer cable, when you should anticipate additional spin and changes in diameter.

Sizing Flow Tubes

Before starting a pressure job, it is essential to understand the diameter of the cable and the amount of wear on the cable. Generally, it is a good idea to measure the wireline with a caliper every 2,000 feet and record the readings in the line record book for future reference when selecting flow tubes. A good rule of thumb is that if the wireline varies in diameter by more than 0.006 inches, it is not a good candidate for pressure work. If you are running deeper than usual or the line has been cut off or shortened, you could be getting to a part of the wireline that has never been off the drum, the same as a new cable. Now, you have a mixture of used seasoned cable and brand-new cable. You must treat it as if the cable is new.

The industry standard for flow tube selection has been 0.004 to 0.006 inches larger than the maximum OD of the wireline entering the well. A wireline cable will vary in size along the entire cable length due primarily to wear and stretch. Flow tubes also wear, causing their inside diameter to increase in size. Understanding your cable and flow tube diameters is critical in getting a good seal during pressure work without compromising the possibility of getting stuck in the flow tubes and potentially breaking the cable.

Crossed Armor Wires

A common problem with using flow tubes that often go unnoticed is “crossed” armor wires. To insert the wireline through the flow tubes, cut off the rope socket and twist the armor wires together. During this step, the armor wire gets crossed unintentionally, as shown in the picture below. This crossed armor may cause problems by getting stuck in the flow tubes on that first run. Or it may get milked up the cable and then show up many runs later thousands of feet up the cable.

The crossed armor wire could also be forced back through the flow tubes by indenting the outer armor into the inner armor and plastic conductor, again going unnoticed. In this case, however, by its very nature, the crossed armor will take most of the wear as the wireline slides through the flow tubes. Eventually, the wire will break and potentially ball up below the flow tubes. This condition, where the inner wire forces through the plastic to the copper, can also result in an electrical short.

The best practice to prevent crossed armors is to stop and check the cable after installing the first flow tube. Slide the first tube back and forth, then run your hand down the cable in front of the flow tube, feeling for any irregularities. If you find a crossed armor wire near the tool end that was not forced through the flow tubes, you can sometimes milk it back to the tool end. However, if the crossed wire is hundreds or thousands of feet up the wireline, the best practice would be to go to the nearest authorized service center to have them return the wireline to operational condition. When a crossed armor has been forced through a flow tube and found, you must cut off the wireline to prevent the possibility of either a broken armor or electrically shorted cable.

Sinker Bars

To enter a live well, you must overcome the force of the well’s pressure by adding sinker bars to the end of the tool string. You can calculate the weight of the sinker bar using the formulae below or go to www.qualitywireline.com and use the sinker bar calculator under “technical support.”

The force pushing the cable out of the well is a function of the pressure in the well and the cross-sectional area of the wireline. Use the following calculations:

Cross-Sectional Area

Where r is the cable radius, and π (Pi) is 3.14

Example:

Wireline 7/32 in. (0.224 in.) with tool string weight (T) of 175 pounds

r 0.224/2 0.112 in.

.14 0.112

A = 0.0394 in.2

The Balance Weight F = P x A

If the wellbore pressure (P) is 7,500 psi

F = 7,500 psi x 0.0394 in.2

F = 295 pounds

This force or balance weight will counterbalance the wellbore pressure. For pulling the wireline into the well, apply an additional weight (overbalance). Generally, that is about 20% of the force, but each operator may have their own rules of thumb.

Ft = F + (20% x F) = 295 + (0.2 x 295) = 354 pounds

Sinker Bar Weight = Ft – T = 354 – 175 = 179 pounds