The oil and gas industry exposes manufacturers and service companies to some of the most challenging environments. During wireline operations, cables routinely run tens of thousands of feet below the earth’s surface, exposing the tools and the cable to pressures over 10,000 psi and temperatures over 400°F, all the while transmitting clean, reliable data. In certain wellbore environments, the temperatures can reach over 600°F, challenging the limits of current technology. This article discusses the effect of temperature on wireline cable and how to ensure success under the most challenging operating conditions.

The maximum well temperature of a cable exposed under ideal conditions defines the temperature rating of wireline cables. Ideal conditions include operating in a vertical well, normal tension profiles, tight armor, and other factors. In the oil and gas industry, downhole operations are seldom ideal, and during pump-down operations, the conditions are even further from ideal. There are so many variables related to cable selection that it is best to rely on field experience in conjunction with input from experts in the manufacturing and operation of wirelines.

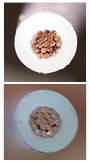

Common knowledge suggests that the plastic is the determining factor in the temperature rating of a cable. Three circumstances, or typically a combination of all three, cause the plastic to deform: tension, temperature, and time. Tension increases the radial compressive forces exerted by the armor on the core (conductor), squeezing the plastic core. If the combination of temperature and tension is high enough, the plastic will exude (ooze) through the inner armor wires over time, as depicted in the photo (above left). Plastic selection is crucial; however, other factors will dramatically increase operational life at elevated temperatures, including: 1) Manufacturing Quality, 2) Cable Conditions, 3) Materials Selection, and 4) Operating Conditions.

Manufacturing Quality

Starting with a good quality product is critical in ensuring the cable will hold up long-term under the challenging conditions that the wireline is exposed to daily. Most wireline manufacturers have similar designs, but the manufacturing processes and quality control vary considerably. The two areas of manufacturing that will impact a wireline’s performance at elevated temperature and tensile loads are the core (conductor) quality and the inner armor coverage.

The Core

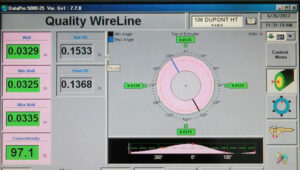

The copper has to be perfectly centered in the core to ensure the maximum amount of plastic insulation separates the armor wires from the copper (top photo). Having a concentric core is critical as the armor squeezes into the plastic. Even today, to check concentricity, many manufacturers cut and inspect both ends of the conductor and assume the 20,000 to 100,000 feet of extruded core between the ends remains consistent. This assumption can result in a section of the core not centered going unnoticed, as shown in the bottom photo. Quality Wireline and Cable uses leading-edge ultra-sonic technology to measure the concentricity 480 times per foot, ensuring the best possible success in critical well operations. The depiction below shows the concentricity device and operator screen controls.

Inner Armor Coverage

Inner armor coverage refers to how much of the core is covered by the inner armor wires. Traditionally, an acceptable range for inner armor coverage would be 97.5% to 99.5%. Higher coverage results in a stiff cable and lower coverage results in problems with plastic prematurely exuding through the inner armor wire (right photo), resulting in loose armor or, in extreme cases, premature electrical failure.

Inner armor coverage refers to how much of the core is covered by the inner armor wires. Traditionally, an acceptable range for inner armor coverage would be 97.5% to 99.5%. Higher coverage results in a stiff cable and lower coverage results in problems with plastic prematurely exuding through the inner armor wire (right photo), resulting in loose armor or, in extreme cases, premature electrical failure.

The first step in ensuring perfect coverage is a perfect core (conductor). The core must be held within a very stringent diameter and ovality control (<0.001”) to attain precise and consistent inner armor coverage during the armoring process. In addition to three separate laser scanners measuring diameter and ovality, Quality Wireline and Cable uses laser lump detection technology to find any potential defect before the cable goes to the field. Quality Wireline and Cable takes precision manufacturing one step further to achieve the ideal coverage of 98.5% through the implementation of synchronous smart electrical drives on tubular stranding machines. This leading-edge technology eliminates the mechanical gearbox and allows infinite coverage precision, resulting in as close to a perfect cable as possible.

Cable Conditions

Because of today’s changing operational practices, including pump-down operations, wireline cables often work under non-ideal conditions that cause the armor to become loose. When the outer armor wires loosen, the inner armor tightens, and the tensile load is transferred from the outer armor wires to the inner armor wires, resulting in abnormally high radial compressive forces on the core. This squeezing of the core (conductor) causes the armor wires to embed further into the plastic, slowly pushing the plastic out between the armor wires. When the plastic is soft at higher temperatures, this squeezing occurs faster. For maximum life from a wireline cable and to operate successfully in high-temperature environments, it is vital to keep the armor tight by servicing it when required.

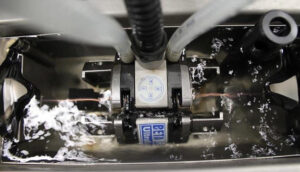

The photo above shows a twister used to tighten the cable. For basic information on loose outer armor and how to determine when the armor is loose, refer to Technical Bulletin 3, available at f-e-t.com/qualitywireline.

Materials Selection

Material selection is critical to ensure the finished wireline performs as designed. Generally, we think of “plastic selection” when considering material choice regarding high-temperature wireline. However, wellbore temperatures can affect the mechanical properties of the armor, as well.

Type of Plastic

Three circumstances cause the plastic to deform: tension, temperature, and time, typically a combination of all three. As tension increases, the radial compressive forces exerted by the armor on the core (conductor) increase, squeezing the plastic core.

If the combination of temperature and tension is high enough, the plastic will exude (squeeze) through the inner armor wires over time, as depicted in the top photo. The lower photo shows a phenomenon called “snakeskin,” where the plastic forms a thin layer between the two armors. This “snakeskin” peels away when removing the outer armor. This loss of plastic on the conductor can result in loose armor and a higher risk of electrical failure.

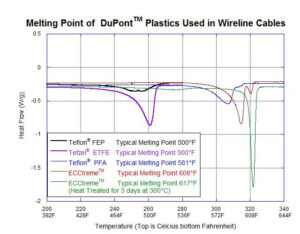

The first step to prevent any exuding is selecting the best application material. The top image in the right column shows the most common DuPontTM materials and their respective melting points for high-temperature wireline applications. Although the melting point of plastics is important, understanding the exuding as a function of temperature, tensile loads, and time is critical. Quality Wireline developed a test apparatus that subjects wirelines to temperatures under high tensile loads simulating downhole conditions. Using the “exuding test” is essential in ensuring operational success before entering high-temperature environments with unknown elements.

Temperature ratings of plastics for wireline cable have been derived primarily from years of operational experience. That is not to say that plenty of science has yet to go into developing and testing these cables. Quality Wireline’s proprietary “Exuding Tester” helps further understand the impact of radial compressive loads on the plastic core as the wireline is exposed to high tensions at elevated temperatures. This test device was instrumental in evaluating and comparing the new 600°F plastic (Q600) before field trials. Furthermore, you can use it to evaluate wireline at any combination of temperature, exposure time, and tensile load.

Type of Armor

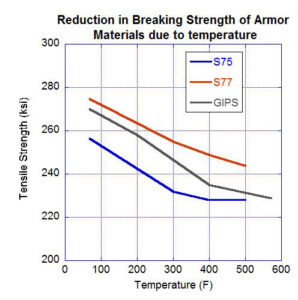

Temperature affects the mechanical properties of GIPS and alloys used for wireline armor, as depicted in the figure on the next page. It is important to understand that wireline cables can lose up to 12% of their breaking strength due to wellbore temperature. Under certain combinations of temperature and tensile loads, the plastic may be suitable where the armor cannot provide the strength required to perform the wireline operations. Understanding potential limitations is paramount before starting operations at high temperatures.

In addition to the loss of strength at elevated temperatures, heat acts as an aggressive catalyst to the corrosion process. In lab studies of high-carbon steel, the corrosion rate doubles every 20°F. Well fluids, in combination with temperature and pressure, are the only accurate way to ensure that you have the correct material for the application, which is also true for both GIPS and alloy applications.

Selecting the appropriate material for sour service lines is best done by applying a quality software program combined with personnel experienced with sour service cables and their application.

Operating Conditions

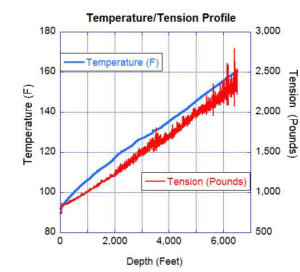

Regarding the temperature effect on wireline, the three most important factors from an operating perspective are understanding the tension profile, temperature profile, and exposure time.

Temperature Profile

In general, the earth has a temperature gradient that is well known and is inconsistent from one geographic region to the next. For example, the bottom hole temperature at 12,000 feet in Texas can range from 120°F to 320°F. Flowing wells in production testing applications will change the natural temperature gradient; uphole wellbore temperatures become much hotter than the thermal gradient would predict. Even stranger, the temperature gradient in steam injection and SAGD (Steam Assisted Gravity Drainage) wells can be upside down, where the hottest part of the wellbore is the wellhead and the coolest part is the bottom hole.

Tension Profile

Typical tension profiles for an ideal vertical well have the full weight of tools and cable at the top of the well, which drops to the weight of the tool at the bottom, similar to the profile shown below. Today, a large percentage of wells are deviated or horizontal, which changes the ideal tension profiles. Abnormal well conditions, pump-down operations, excessive tool drag, stuck tools, or the tool or cable being differentially stuck will result in the tension profile changing dramatically and a higher percentage of the full load moving to a point in the cable different from the drum or wellhead.

In an ideal well, the highest tensions are at the lowest temperatures, and the lowest tensions are at the highest temperatures. With the growth of the horizontal market and advancements in thermal technologies today, this is only sometimes the case. Combining the higher temperatures with higher tensions creates a challenging environment for the wireline and one that the operator needs to be aware of.

Exposure Time

As the wireline enters the wellbore, it increases in temperature over time. For example, in a dry gas well, it takes about one hour for the core of a 9/32-inch cable to increase in temperature from 60°F to 450°F. The same cable in a fluid-filled well may heat up in several minutes. If you can perform the operations in less time, the plastic remains hard, and there is less potential for damage to the cable. In most wells, the time duration of exposure to the cable at the highest temperature is the least because this peak temperature occurs at the deepest part of the well. However, this is not always the case, as previously discussed. Understanding the relationship between time, temperature, and tension helps to ensure you select the best cable for your operations.

To achieve the most extended life from cables operating under elevated temperatures, it is imperative that you first start with a manufacturer that understands the intricacies of working in these harsh environments and has invested in the equipment and expertise to manufacture the best possible product. Combining field experience with manufacturing expertise to select the best cable to meet your operating parameters and ensuring the cable remains in excellent working condition are key to success. Quality’s constant development of process improvements, unique synchronous drive system, advanced extrusion system, and search for new and improved products have kept Quality at the forefront of higher success in deep/hot challenging wellbore environments.