Meltable Plug

Custom stopgap product post type

Meltable Plug

Dissolvable Plug

Knockout Plug

Flow Control Device

Shiftable tool option for on/off capability

FET Variperm’s OptiCon® flow control portfolio is founded on extensively applied research and proven field performance in over 1,000 wells globally. Our tools deploy in multiple applications, including but not limited to SAGD, CSS, steamflooding, and waterflooding. Learn more about how we can support your next project.

Our flow control technologies are classified as follows:

In deepwater operations, protecting tubing and work string from riser contact is essential to avoid costly damage. Our thermoplastic centralizers, crafted from advanced DuPont™-engineered materials, are built to meet this challenge with strength and precision.

Each centralizer is injection molded for consistent quality and features a durable, single-piece design that simplifies installation and enhances performance. With custom slots for control lines and a secure, self-contained wrap, these centralizers deliver unmatched stability and reusability in demanding offshore environments.

Part of FET’s Cannon Services product line and our comprehensive MultiLift artificial lift solutions, these centralizers are engineered to perform again and again.

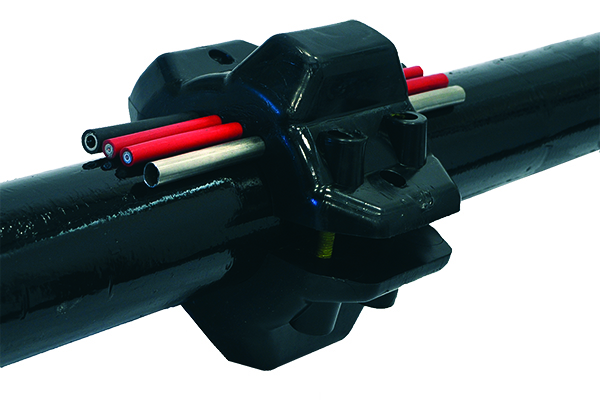

Umbilical cables are the vital conduits of power, fluid injection, control, and communication in deep-sea drilling. As offshore production moves farther from shore, the risk of umbilical damage and the associated costly downtime increases dramatically.

FET’s umbilical protectors are engineered to safeguard these critical systems. Designed to retain and shield cables within marine risers, each assembly features a specialty strap collar that custom-fits the outer diameter and durometer of individual cables. Built from noble, corrosion-resistant materials, these protectors offer long-term durability and high reusability in harsh subsea environments.

Part of our trusted Cannon Services product line and the broader MultiLift artificial lift solutions catalog, these protectors are built to perform where it matters most.

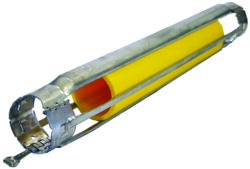

FET’s patented VIT protectors are engineered to safeguard your most critical downhole components. Designed to secure vacuum-insulated tubing (VIT) sleeves while stabilizing adjacent control lines, these protectors ensure safe, efficient installations in even the most complex offshore and subsea environments.

With customizable configurations for tubing, casing, and control lines, our VIT protectors offer exceptional reusability, helping reduce project costs and extend equipment life.

Part of the trusted Cannon Services product line and our comprehensive MultiLift artificial lift solutions, these protectors are built for performance and longevity.

Forum’s vacuum-insulated tubing (VIT) sleeves are designed to deliver superior thermal insulation at VIT connection points where heat loss is most critical. Built to perform in a wide range of wellbore conditions, these sleeves help maintain thermal stability while supporting multiple tubing, casing, and control line configurations.

Crafted for multiple use cycles, our VIT sleeves offer long-term durability and significant cost savings on future workovers. Whether you’re operating in deepwater or high-temperature environments, these sleeves are a reliable solution for protecting your thermal integrity.

Part of the Cannon Services product line and our extensive MultiLift artificial lift solutions catalog, FET’s VIT sleeves are trusted by operators worldwide.

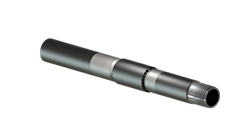

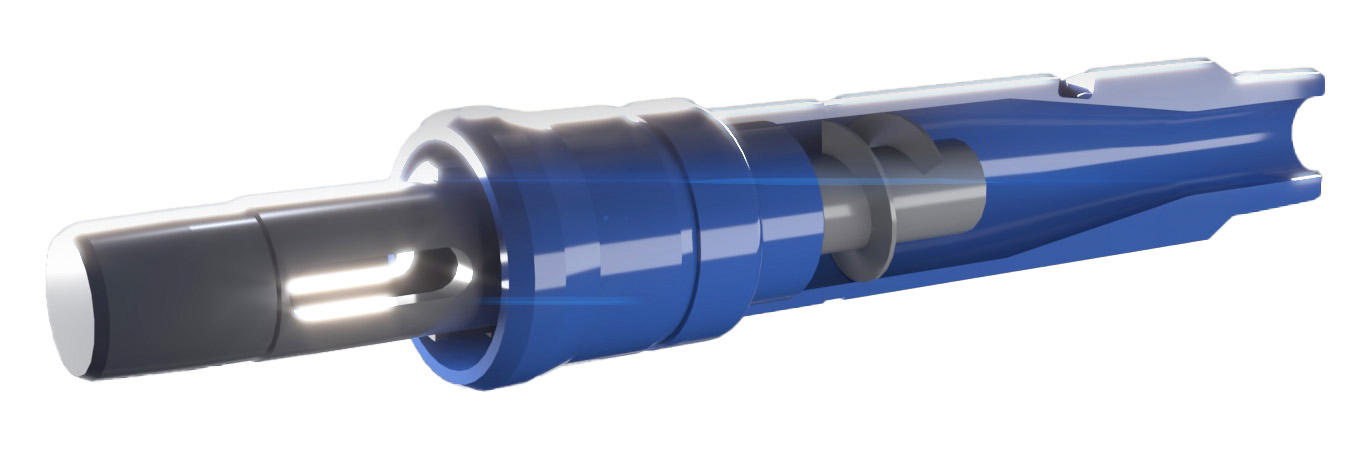

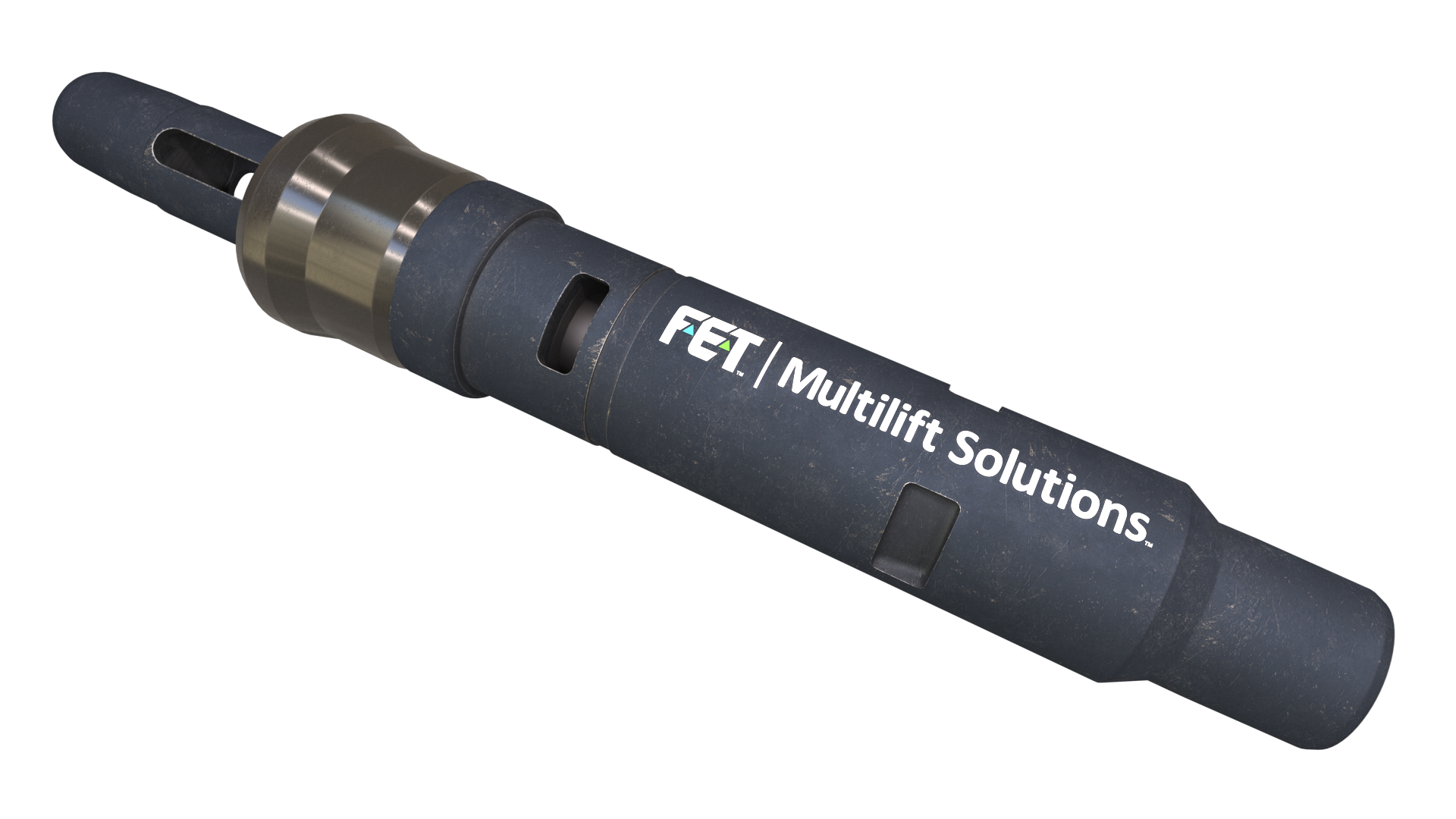

Cyclone ESP harnesses the power of proven vortex technology to deliver superior sand protection for electric submersible pumps (ESPs). Designed for versatility, it performs reliably in onshore, offshore, deviated, and horizontal wells in protecting your equipment, extending pump run life, and significantly reducing lease operating expenses.

With a universal one-size design, Cyclone easily retrofits into any ESP well. Installed directly below the pump, it requires no downhole preparation, making deployment fast and hassle-free. Its high-efficiency centrifugal action separates a broader range of sand grain sizes than traditional sand screens, directing clean fluid to the pump and diverting solids to a tailpipe below.

Constructed from specialized metallurgy and featuring no moving parts, Cyclone avoids the erosion, plugging, and maintenance issues common with conventional sand control methods. The result is a robust, low-maintenance solution that delivers consistent performance in even the harshest environments.

Discover how Cyclone ESP can enhance your sand control strategy, delivering efficiency, durability, and peace of mind in every well.