Vacuum Insulated Tubing Solutions

VIT Protection

Our patented vacuum-insulated tubing (VIT) protectors secure and protect VIT sleeves while also protecting and stabilizing control lines that run adjacent to the tubing. Customize your solution using multiple tubing, casing and control line configurations, all with proven reusability that reduces project costs.

Forum’s VIT protectors are part of our Cannon Services product line and extensive MultiLift artificial lift solutions catalog.

Benefits

- Protects VIT from costly damage during installation and retrieval.

- Offers high reusability, increasing cost savings on well recompletions.

- Installs in the most complex offshore/subsea well designs.

Features

- Interchangeable designs (fits tubing sizes with outside diameters of 2.375-13.75 inches or greater)

- Custom designed to accommodate multiple control line configurations

- Custom designed for multiple connection and sleeve combinations

- Options for corrosion-resistant alloy and other specialty steels

Applications

- Protecting control lines and securing VIT sleeves

- Typically utilized in offshore or subsea environments

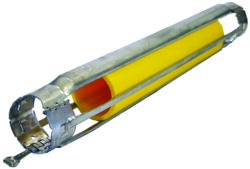

VIT Sleeves

Vacuum-insulated tubing (VIT) sleeves limit thermal exchange on VIT connections. Fully compatible with a variety of wellbore conditions, our VIT sleeves provide maximum insulation for multiple tubing, casing and control line configurations. Designed for multiple use cycles, these sturdy sleeves provide significant cost savings on future workovers.

Forum’s VIT sleeves are part of our Cannon Services product line and extensive MultiLift artificial lift solutions catalog.

Benefits

- Offers high reusability, increasing cost savings on well recompletions.

- Installs in the most complex offshore/subsea well designs.

Features

- Interchangeable designs (fits tubing with outside diameters of 2.375-13.75 inches or greater)

- Custom designed to accommodate a wide variety of VIT connection combinations

- Specifically engineered dimensions for requested insulating parameters

- Molded from a variety of materials for maximum thermal insulation and wellbore compatibility

Applications

- Critical thermal stability applications

- Typically utilized in offshore or subsea environments