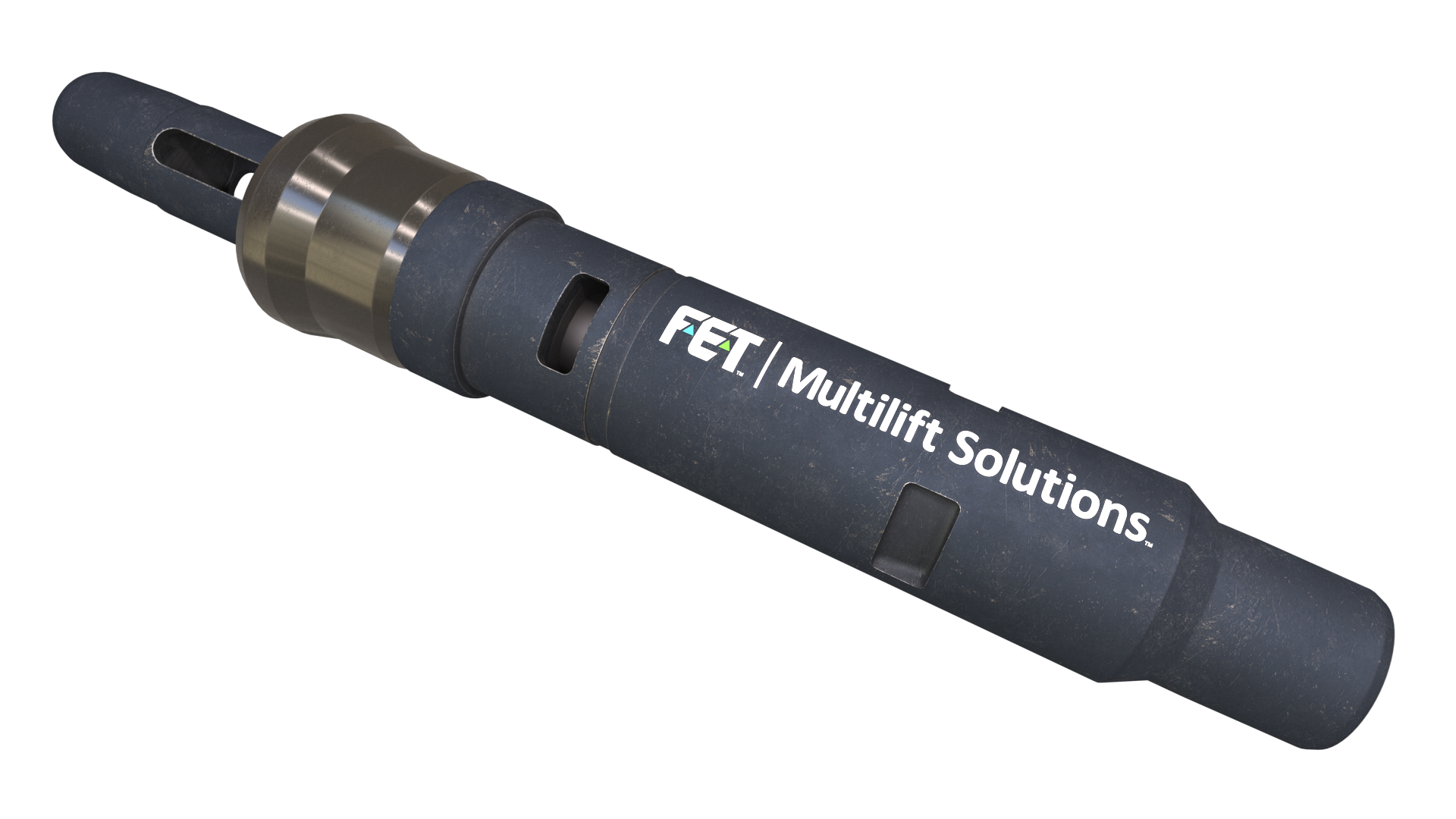

ABS MagneGuard™ — Automatic Safety for PMM-Driven ESP Systems

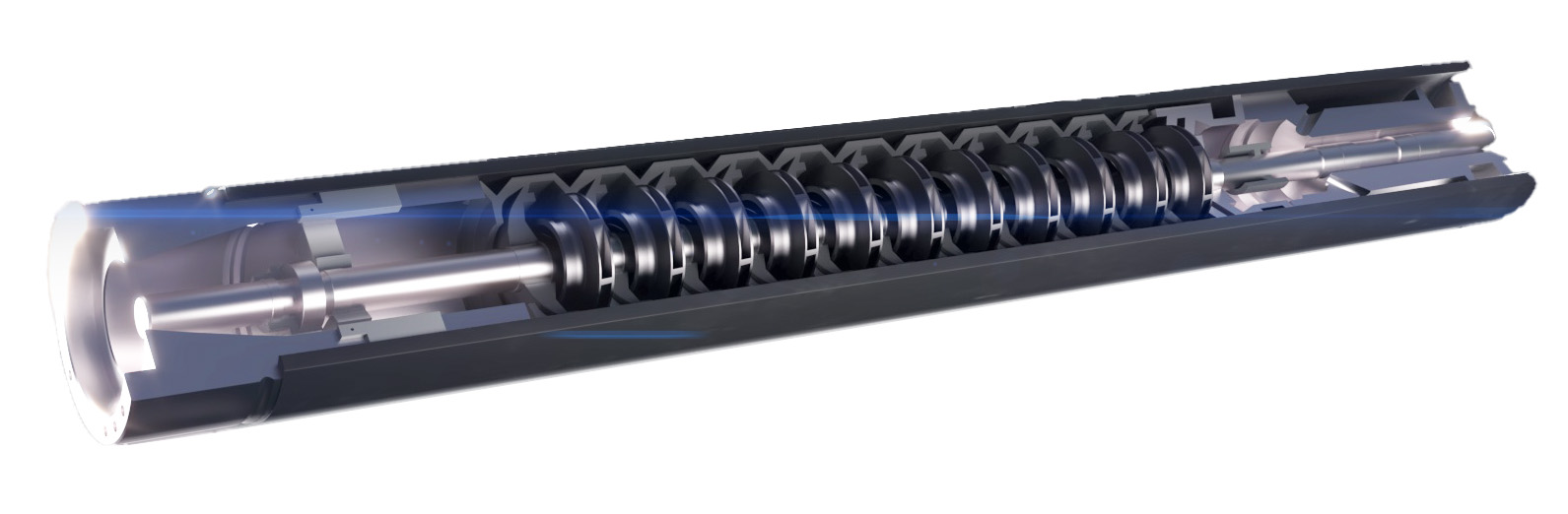

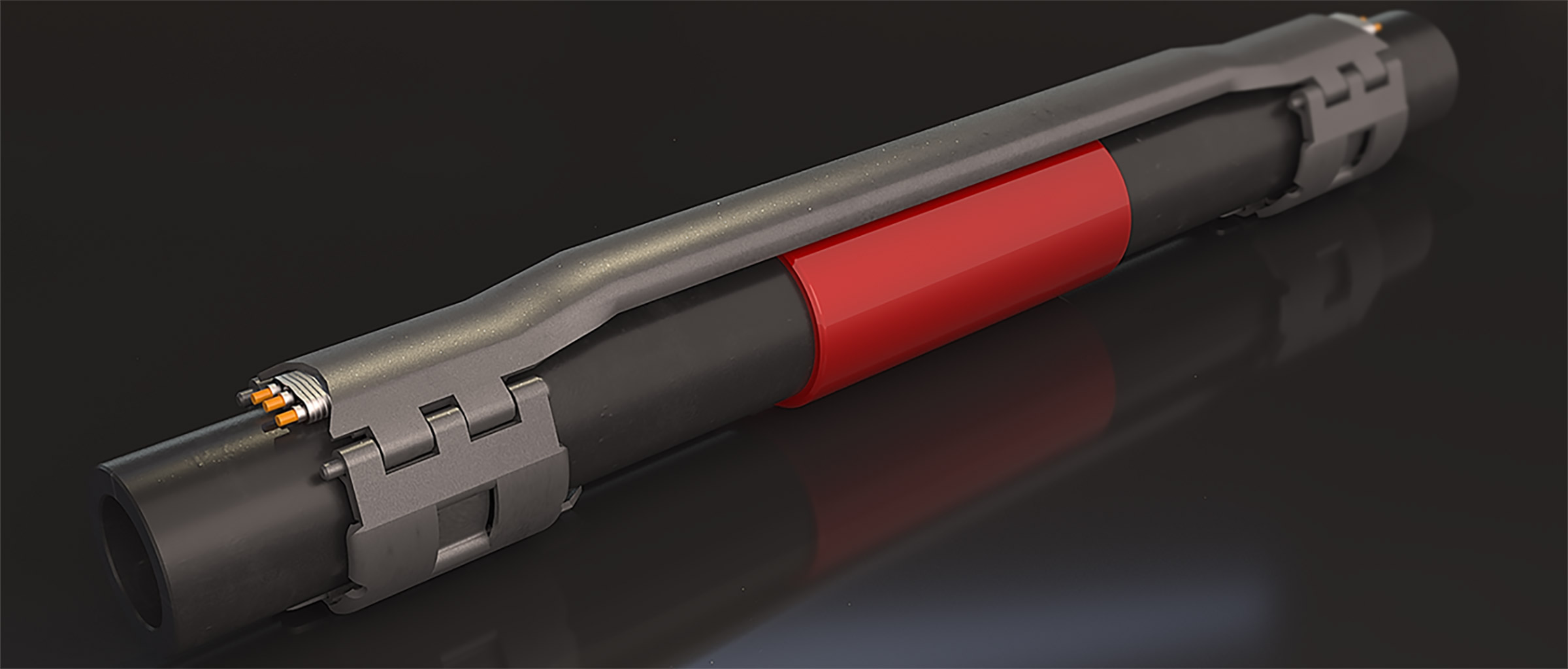

Permanent Magnet Motor (PMM)-driven ESPs are increasingly used for efficient fluid extraction. They also introduce a serious safety risk: Electric Shock. When the motor shaft rotates due to hydraulic forces, it can generate high voltage along the cable, even when the system is powered down, creating a hazardous environment for field personnel during workovers and maintenance.

FET Multilift Solutions’ ABS MagneGuard™ is engineered to eliminate this risk automatically, providing critical protection and enabling the safe operation of PMM-driven ESP systems. Unlike traditional methods, such as manually shorting the cable at the surface, MagneGuard requires no intervention, reducing human error and enhancing safety.

How It Works

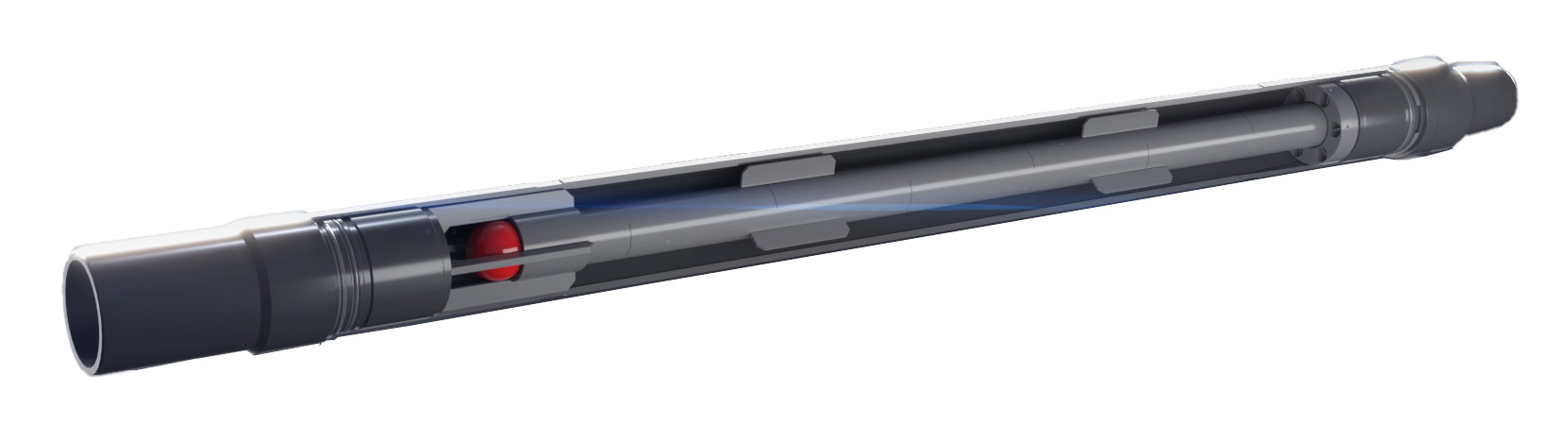

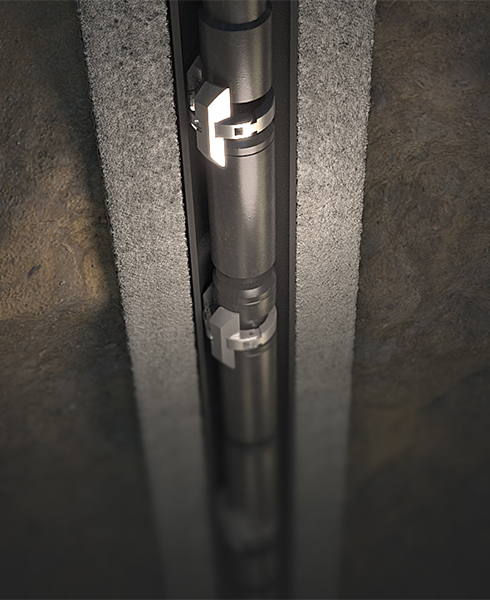

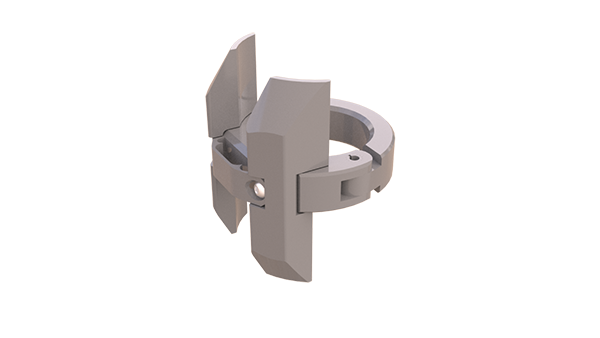

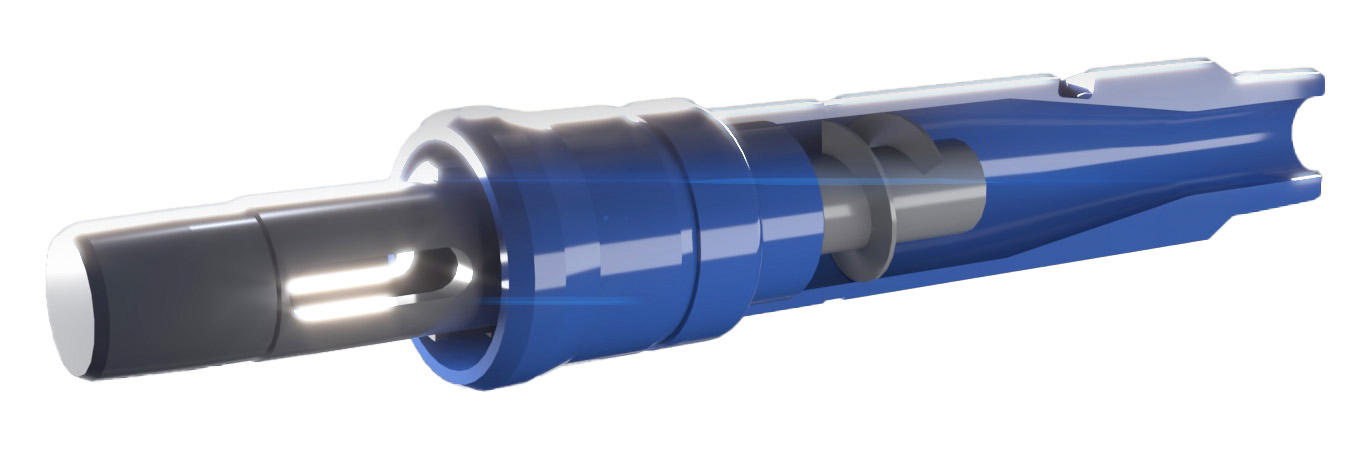

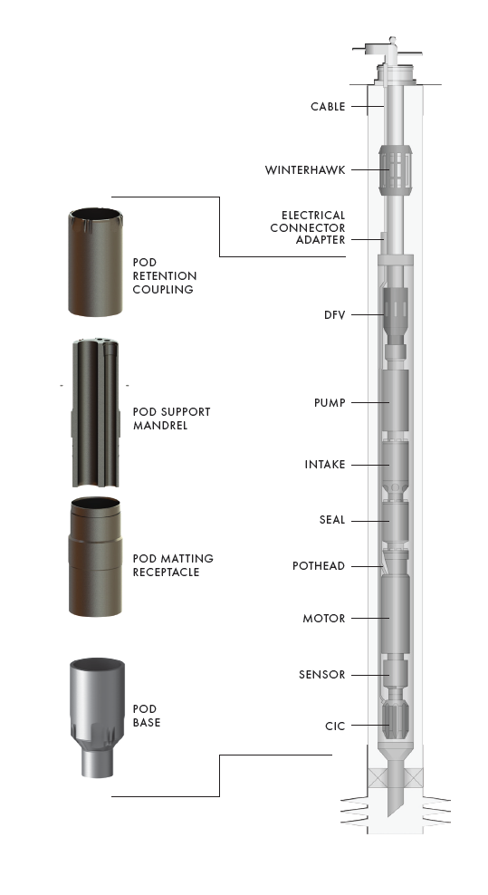

Installed directly on top of the pump head, ABS MagneGuard prevents shaft rotation caused by fluid movement during run-in-hole (RIH), fallback, or other non-operational states. It works seamlessly with any ESP system, regardless of manufacturer, and does not interfere with pump performance.

Benefits

- Enhanced Personnel Safety: Automatically eliminates the risk of electric shock—no manual steps required.

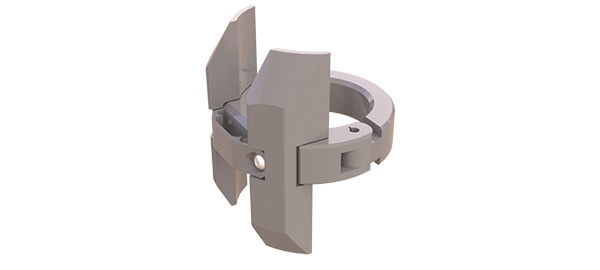

- Operational Simplicity: Installs easily with a bolt-on design—no special tools or procedures.

- Cost Efficiency: Reduces rig time and eliminates the need for third-party safety services.

- Accelerated PMM Adoption: Removes a key barrier to the widespread use of permanent magnet motors.

Key Features

- Universal Compatibility: Works with all ESP manufacturers and configurations.

- Non-Intrusive Design: Mounts above the pump head without altering the system setup.

- Automatic Protection: Prevents shaft rotation and voltage generation during non-powered states.

- No Moving Parts: Reliable, maintenance-free operation.

Explore how ABS MagneGuard™ can make your ESP operations safer, simpler, and more efficient—without compromise.