Secura Line Stage Collars

SecuraSeal™: Smarter Cementing. Safer Wells. Lower Costs.

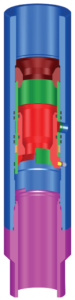

FET’s Davis-Lynch SecuraSeal™ packer stage cementing collar combines an inflatable packer and stage collar into one powerful tool, streamlining operations, cutting costs, and enhancing well integrity.

One Tool. Multiple Functions.

PSC replaces two tools with one integrated solution—saving time, labor, and procurement complexity. A single technician can run the tool, reducing personnel and equipment needs.

Key Benefits

- Cut Costs & NPT

Reduce well construction time and eliminate the need for separate tools. PSC simplifies operations and lowers total spend. - Enhance Zonal Isolation

Isolate hydrostatic pressure between cement stages and seal off pressurized or gas-prone zones—minimizing gas migration and surface issues. - Boost Safety & Compliance

Meet regulatory standards and reduce HSE risks in trouble zones with precision cement placement. - Minimize Remedial Work

Achieve better first-stage cement jobs and reduce the need for costly squeeze cementing. - Eliminate Flat Time

Fast deployment and simplified logistics mean less downtime and more efficiency.

Engineered for Performance

- Mechanically anchored, spring steel-reinforced inner tube

- Oil-resistant rubber outer layer

- Expands via fluid injection for a full-length seal in cased or open holes

- Built-in ratchet mechanism ensures mechanical backup in case of hydraulic failure

Why Choose SecuraSeal™?

- Runs in sequence with casing

- Instantly ready for second-stage cementing

- Compatible with water- and oil-based muds

- Supports first and second-stage plugs

- Proven reliability in complex well environments

Ready to simplify your cementing operations?

Contact us to learn how SecuraSeal™ can deliver performance, safety, and savings in one smart solution.

Key Features

- Made in Texas under API-Q1 certified manufacturing

- Integrated sleeves with locking, non-rotating drill-out design

- Compatible with most casing grades, threads, and up to 30° well deviation

- High-temp rated: up to 275°F standard, 375°F with special seals

- Composite seat stable to 350°F

- Customizable pressure settings for sleeve operation

- Multiple plug set options available

- Inflatagrip® patented element – non-welded, reinforced, and fully supported during expansion

- Reliable sealing with stationary internal seal design

- No filament-wound materials in composite construction

- Factory pressure-tested inflatable elements and seals

- Robust valving ensures proper inflation and closure

SecuraCollar™M - Type 778MC

SecuraCollar™ Composite Stage Cementing Collar

Built for Performance. Engineered for Efficiency.

Continuing Forum’s legacy of innovation, the SecuraCollar™ delivers enhanced drill-out performance and superior sealing for 2- or 3-stage cementing operations. Leveraging the trusted Davis-Lynch™ mechanical design, SecuraCollar™ integrates a high-strength composite opening seat for unmatched reliability and efficiency.

Why SecuraCollar™?

- Proven Design

Based on Davis-Lynch™ stage collars trusted since 1993. - Faster Drill-Out

Over 10% reduction in drill-out time—saving rig time and costs. - High-Strength Composite Seat

Same durable material used in Forum Frac Plugs, with anti-rotation locking for smooth drill-out. - Clean Drill-Out

No continuous composite rings left behind—protects PDC bits and prevents hang-ups. - Superior Strength

Convolute-Tube composite maximizes burst, collapse, and shear resistance. - Optimized for PDC Bits

No filament-wound materials to slow penetration rates. - Thermally Stable

Dimensionally stable composite rated up to 350°F.

SecuraCollar™ is the next evolution in stage cementing—designed to simplify operations, reduce costs, and deliver dependable performance in demanding well environments.

Contact us to learn how SecuraCollar™ can elevate your cementing strategy.

Mechanical - Type 778MC

SecuraCollar™ M

Precision Engineered. Field Proven. Performance Enhanced.

The SecuraCollar™ M is the next-generation mechanical stage cementing collar from Forum’s Davis-Lynch™ line—designed for demanding environments and optimized for superior sealing, faster drill-out, and enhanced durability. While already field-proven, ongoing R&D continues to push boundaries in material science and tool performance.

Built for Tough Wells

- High-Strength Construction

Manufactured from premium materials rated up to 150,000 psi yield strength, including sour gas-compatible options. - Gas-Tight Sealing

Metal-to-metal seal backed by elastomer ensures pressure integrity in critical zones. - No Welds. No Weak Points.

Fully machined design eliminates welds, reducing stress concentrations and enhancing reliability. - Compact & Durable

Reduced tool length minimizes bending stress and improves handling in deviated wells (up to 30°).

Optimized for Drill-Out Efficiency

- Fast, Clean Drill-Out

Composite sleeves lock against rotation and leave no continuous rings—protecting PDC bits and speeding up operations. - Minimal Debris

Only small amounts of aluminum and rubber encountered during drill-out. - Pressure-Relief Design

Prevents fluid trapping during closing phase for smoother operation. - Secure Closure

Internal lock ring holds the closing sleeve firmly in place.

Versatile Cementing Options

- Compatible with four plug set configurations for flexible cementing strategies

- Stationary seals maintain integrity throughout operation

- Rated for temperatures up to 350°F with dimensionally stable composite materials

SecuraCollar™ M delivers unmatched reliability, sealing performance, and operational efficiency—making it the smart choice for complex wellbore environments.

Contact us to learn how SecuraCollar™ M can elevate your cementing operations.

SecuraCollar™ H - Hydraulic - Type 777HY

SecuraCollar™ H

Hydraulic Precision for Horizontal Cementing

Engineered for the demands of modern horizontal drilling, SecuraCollar™ H brings hydraulic innovation to stage cementing. With a pressure-activated opening sleeve and proven mechanical sealing, it eliminates the need for mechanical opening devices—making two-stage cementing in highly deviated wells simpler, faster, and more reliable.

Hydraulic Advantage

- Hydraulic Opening Sleeve

Differential area design delivers high opening force with minimal pressure—ideal for horizontal applications. - Immediate Activation

Opens right after first-stage cement displacement for seamless operation. - Customizable Opening Pressure

Tuned during assembly to coordinate with inflatable packers and other hydraulic tools in the string.

Versatile Cementing Solutions

- Enables selective cementing of casing intervals using inflatable packers

- Compatible with slotted or pre-drilled liners below the packer for zone isolation

- Eliminates need for continuous displacement plugs in deviated wells

Proven Performance Features

- Inherits all reliability features of the 778 MC mechanical collar

- Metal-to-metal and elastomer backup seals ensure gas-tight integrity

- No welds—reducing stress points and enhancing durability

- Stationary seals minimize damage risk during operation

- Locking sleeves prevent rotation for smooth, fast drill-out

- Minimal aluminum and rubber debris during drill-out

- Supports four plug set configurations for flexible cementing strategies

SecuraCollar™ H is the smart solution for horizontal and complex wellbore environments—combining hydraulic precision with trusted mechanical integrity.

Contact us to learn how SecuraCollar™ H can streamline your cementing operations.

Proven. Powerful. Effortless by Design.

Engineered for off-bottom cementing, the SecuraEase™ Pump-Out Stage Collar is a patented solution trusted in the field since 1999. Designed for 7” K55 23 ppf casing, this system delivers reliable staged cementing performance in demanding well environments.

Integrated Cementing System

The SecuraEase™ system combines:

- A 7-ft inflatable packer

- An integral stage tool

- A ball seat/float collar

Each component meets or exceeds casing specifications for strength and reliability, ensuring optimal performance in coal bed methane wells and other challenging conditions.

Key Benefits

Stronger Well Integrity

Achieve zonal isolation and prevent gas leaks for safer, more secure operations.

Faster, Simpler Operations

The pump-out design eliminates the need for retrieval tools, saving valuable rig time.

Built for Unique Conditions

Proven performance in Australia’s coal bed methane wells and other complex environments.

Boosts Production

The full bore design enhances flow and improves overall well performance.

Effortless Conversion & Full Bore Access

After cementing:

- Internal components shear out and drop downhole

- Full bore access is restored

- Components are 0.240” smaller than casing drift ID, ensuring smooth passage

The split ring system secures internal parts during deployment and allows seamless conversion. The packer element guarantees a dependable seal between tool and casing.

Trusted Technology

Built on Variperm’s packer elements, first introduced in 1999 and now proven in over 10,000 successful runs.

How It Works

- Tool is lowered into the well; ball lands on seat

- Packer expands; rupture disc opens flow path

- Cement is circulated; closing plug follows

- Pressure releases internal components

- Components drop to bottom, leaving full bore access

SecuraSlim™ Stage Collar

The Slimmest Collar for the Toughest Wells

Engineered for the demanding conditions of the Permian Basin, the SecuraSlim™ Stage Collar offers unmatched reliability in tight clearance zones. With the smallest outer diameter (OD) on the market, it’s designed to maximize performance while minimizing casing costs.

Built for the Permian Basin

SecuraSlim™ is small but strong—enabling casing that saves money and performs from surface to total depth. Whether you’re navigating New Mexico’s strict hole-to-pipe spacing regulations or pushing the limits of your well design, SecuraSlim™ delivers.

Key Benefits

- Smallest OD on the Market

Navigate tight clearance zones with ease—ideal for regulatory environments with strict spacing requirements. - Casing String Cost-Savings

Run smaller casing sizes without compromising performance. Reduce material costs while maintaining full structural integrity. - Strength You Can Trust

Matches casing burst and collapse ratings, ensuring your stage collar is never the weak link in your string.

Technical Specifications

| Feature | Specification |

|---|---|

| Casing Size | 8 5/8 in |

| Casing Weight | 32 lb/ft |

| Casing Grade | P110-ICY |

| Burst Pressure | 9180 psi |

| Collapse Pressure | 4000 psi |

| Temperature Rating | 300 °F |

| Max Outer Diameter | 9 in |