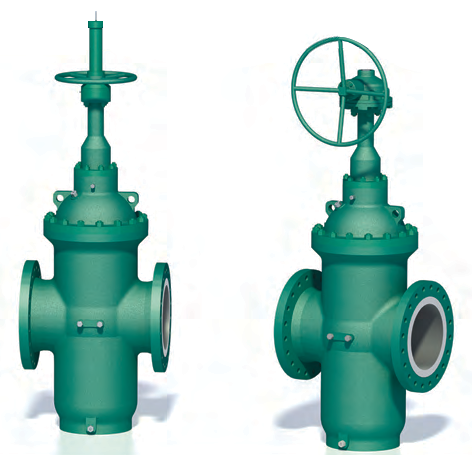

API 6D Gate Valve

FET engineers its PBV® through conduit valves (6D gate valves) to use line pressure force for tight mechanical sealing upstream when high differential pressure occurs. Internal springs achieve low-pressure sealing as they help push seat rings against the gates.

These bi-directional, double block-and-bleed slab gate valves are through conduit, piggable, and top entry. Suitable for transportation pipelines for gas, crude oil, and oil products, all valves are available in various materials and configurations to meet your project requirements.

Benefits

- Chevron-style polytetrafluoroethylene (PTFE) packing for long-lasting, trouble-free stem sealing

- Seats to ensure low- and high-pressure sealing and body cavity self-relief

- Stem injection fitting for secondary sealing

- Smooth, electroless nickel-plated slab for bubble-tight sealing and low operating torque

- Seat injection fitting with internal check valve for emergency sealing

- Drain valve for block-and-bleed function and seat integrity verification

- Valve serialization for complete traceability

- Stem design with internal stops to prevent over-track of slab (no adjustments required)

- Secondary metal-to-metal sealing for fire-safe requirements

Features

- Full bore, through conduit, bi-directional flow

- Product range: two to 24 inches

- Full port

- Pressure class: American National Standards Institute (ANSI) 150, 300, 600

- Flange standards: American Society of Mechanical Engineers/ANSI B16.5, B16.47

- Face-to-face dimensions meet American Petroleum Institute (API) 6D standards

- Basic designs, inspections and testing also meet API 6D standards

- Fire testing to API 6FA standards

- National Association of Corrosion Engineers-compliant nuts and studs (MR0175 2015)