Weight Indicators

Anchor Type Weight Indicators

Instant, accurate indications of total hook load and net weight on bit enable faster, more efficient drilling

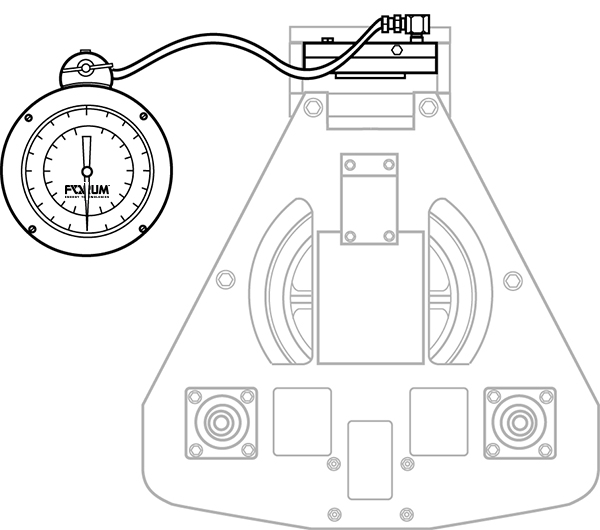

Panel-mounted as an integral part of drillers’ consoles or box-mounted for portability, Forum hydraulic deadline Anchor-type Weight Indicators help the driller maintain consistent weight on bit for faster, more efficient, and more economical drilling.

Driller’s Box with Anchor-type Weight Indicator

Features

- Custom configurable with your choice of instruments:

- Mud pump pressure gauge

- Mud pump stroke meter (SPM)

- Rotary table meter (RPM)

- Electric torque meter

- Tong-torque gauge

- Models available for deadline loads of 30,000 to 200,000 pounds.

- Gauge includes outer dial for direct weight-on-bit reading and inner dial for total hook load.

- Includes vernier bit weight indicator with 4:1 sensitivity for highest possible accuracy.

- Includes a high pressure hose and disconnect fittings.

- Dampers stabilize pointer in case of rough drilling or jarring.

Benefits

- Large, easy-to-read gauge

- Compatible with all industry-standard deadline anchors

- Built to last — delivers accurate measurements even in extreme drilling and environmental conditions

Anchor-Type Weight Indicator Models

| Model | Maximum Load (pounds) | Lines | Indicator Diameter (inches) |

|---|---|---|---|

| 200 | 200,000 | 10, 12, 14, 16 | 16 |

| 150 | 150,000 | 10, 12, 14, 16 | 16 |

| 125 | 125,000 | 10, 12, 14, 16 | 16 |

| 100 | 100,000 | 8, 10, 12, 14 | 16 |

| 75 | 75,000 | 6, 8, 10, 12 | 16 |

| 50 | 50,000 | 6, 8, 10, 12 | 16 |

| 40 | 40,000 | 4, 6, 8, 10 | 12 or 8½ |

| 30 | 30,000 | 4, 6, 8 | 8½ or 6 |

Bulk Tank Systems

Accurate load measurements for bulk tanks and hoppers

Forum Bulk Tank Systems provide extremely accurate load measurements for bulk Gauge, a Compression Load Cell (for bulk tanks) or a Tension Load Cell (for hoppers), and a Hydraulic Hose.

Features

- Accurate measurements in extreme conditions — operational in ambient temperature range of -20° to 120° F (-29° to 49° C).

- Gauge dial faceplates available calibrated in pounds, tons, or kilograms.

- Operator-adjustable damper smooths gauge pointer sensitivity.

- Operator-adjustable dial gear rotates the dial for easy tare adjustment.

- Compression or tension load cells available.

- Standard 25-foot hydraulic hose, with additional lengths available.

- Hydraulic hose available in 3/16-inch diameter, single wire braid construction

or 1/4-inch diameter, double wire braid construction. - Bulk tank hinges available.

To order specify

- Sensors required

- Dial capacity

- Load cell configuration

- Hose length

Bulk Tank System

Hopper System

Compression Load Cell

Gauge

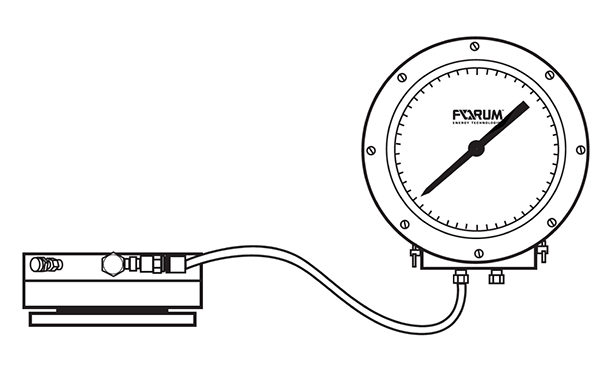

Deflection Type Weight Indicators

Compact, versatile, portable weight indicator for small drilling and workover rigs

Designed for use on small drilling units, the Forum Deflection-type Weight Indicator is easy to move from rig to rig. The Weight Indicator system consists of a Gauge and a Deadline Diaphragm, connected by a high-pressure Hose. The deadline diaphragm converts line-load into a hydraulic pressure signal that is transmitted to the gauge. All system components fit inside a steel container for convenient, compact storage. Built-in handles make the entire system easy to transport.

Features:

- Ready for immediate use — Each system is assembled, loaded with Forum indicator fluid, calibrated, tested, and sealed before shipment.

- Adjustable dampers allow operator-controlled pointer sensitivity.

- Can be mounted near the driller or on the mast or derrick, for optimum setup in any drilling situation — avoiding problems that can result from deadline-mounting, such as buffeting by line vibration.

- Equipped with 10 different dials calibrated for number and size of line in pounds, kilograms, or decanewtons, for easy, flexible measurement readings.

- Rugged, compact container with built-in handles makes this system easy to transport — even by one person.

Benefits

- Large, easy-to-read gauge

- Compatible with all industry-standard deadline anchors

- Built to last — delivers accurate measurements even in extreme drilling and environmental conditions

To order specify:

- Size of rig

- Size of drilling wireline

- Derrick capacity in pounds

- Number of lines strung

- Hose length

Gauge and Steel Container 17 inches high x 14 inches wide

Deadline Diaphragm

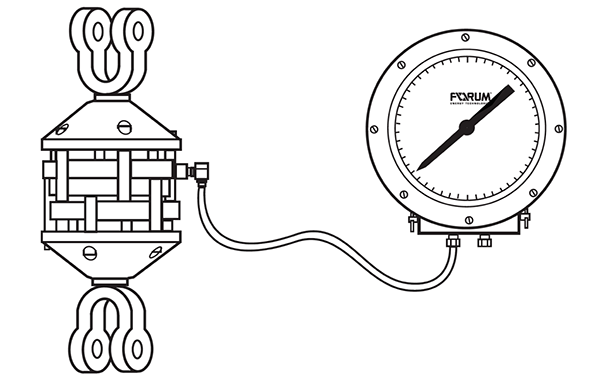

Measure Head Weight Indicator Systems

Rugged weight indicator systems for precision force and tension measurements

Forum Measure Head Weight Indicator systems provide precise, accurate measurement of downhole tool weights during wireline operations. Each hydraulically-operated system includes a Compression Load Cell and a Gauge, connected by a Hydraulic Hose.

Features:

- Each system assembled, calibrated, loaded with indicator fluid, and tested before shipment.

- Standard gauges include 10:1 ratio vernier scale.

- Single-pointer gauges available.

- Easy-to-read 6-inch dial gauge faceplate displays weight in pounds, kilograms, and decanewtons.

- Available in a range of capacities: 5000, 6000, 10,000 and 20,000 pounds.

- Integral damper assembly increases pointer sensitivity —

for accuracy even with the smallest loads. - Custom logos available for gauges.

- Compression load cells and replacement diaphragm rubbers available for 2- and 3-foot measure heads.

Benefits

- Precision ball bearing gauge movements and calibration

to ± 0.5% accuracy ensure reliable readings, reducing loss of valuable downhole tools. - Rugged design for operation in extreme environments, within ambient temperatures of -29° to 49° C (-20° to 120° F).

- Operator-adjustable pointer response time and calibration controls for custom onsite adjustment.

- Offers years of cost-effective, low maintenance service. Routine repairs can be performed by the operator.

Gauge (A71-series)

Gauges have precision ball bearing movements

12 Square-inch Compression Load Cell (40-612)

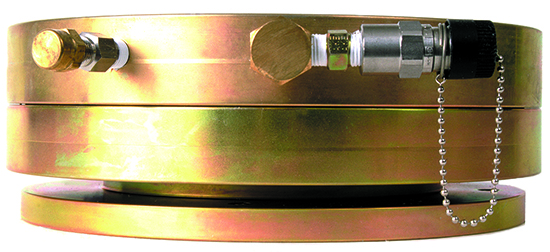

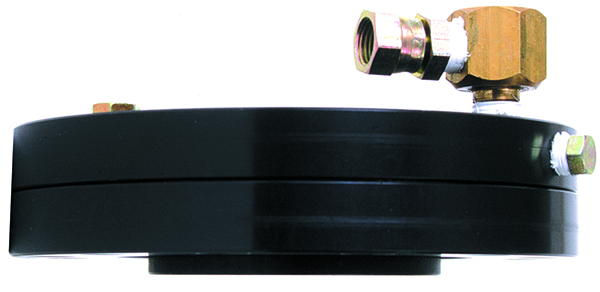

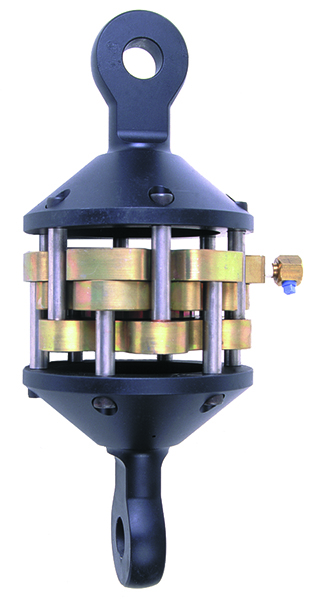

Midget and Super Midget Weight Indicator Systems

Rugged, portable weight indicator systems ideal for small rigs and well service units

Housed in sturdy portable consoles, Forum hydraulic Midget and Super Midget Weight Indicator systems provide accurate weight indications for small rigs and well service units. Each system includes an Indicator, a Load Cell, and a Hydraulic Hose.

Features

- Hydraulically operated — loaded with hydraulic fluid before shipment

- No external power source required

- Accurate measurements in extreme conditions — operational in ambient temperature range of -50° to 150° F

(-45° to 65° C) - Accuracy as shipped from the factory of ± 1/2 of 1 percent of full scale capacity

- Maximum capacity of 25,000 pounds per line (Midget) and 30,000 pounds per line (Super Midget)

- Available in 6″ or 8 1/2″ gauge

To order specify

- Size of rig

- Derrick capacity in pounds

- Size of drilling wireline

- Number of lines

- Required hose length (25-foot standard)

Midget and Super Midget Weight Indicator Systems

| System | Maximum Load | Load Cell |

|---|---|---|

| Midget | 25,000 pounds | 101260 |

| Super Midget | 30,000 pounds | AO16 |

Indicator in Metal Console

AO16 Load Cell for Super Midget Systems

101260 Non-spin Load Cell for Midget Systems