Fluid End Accessories

Pistons

FET manufactures high-quality pistons for regular and high-temperature applications as part of our full line of mud pump system solutions. We offer a full range of pistons from standard rubber to specially engineered urethane that can be used in various drilling fluids to meet your specific drilling requirements. FET offers additional fluid end pump parts, including drilling valves, seats, liners, and gaskets. Contact your FET representative to learn more.

Endurohead

- High-pressure 7500psi application

- Rated Temp: 240° F [115° C]

- Dual durometer solid-body construction with flex lip feature

- Improved bullet nose design

- Resistant to most drilling fluids including Brine

- Suitable for Ceramic and Zirconia liners

- Flex lip provides piston with continuous sealing capability

Red Head

- High-pressure 7500psi application

- Temp resistance: 180° F [82° C]

- Dual durometer lip seal construction

- Accommodates small misalignments of the rod systems

- Resistant to most drilling fluids

- Suitable for Ceramic and Zirconia liners

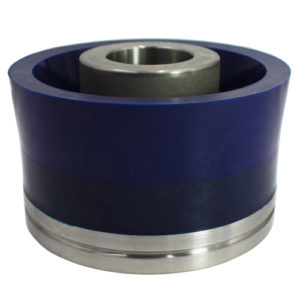

Blue Devil

- High-pressure 7500psi application

- Rated Temp: 240° F [115° C]

- Dual durometer lip seal construction

- Accommodates small misalignments of the rod systems

- Resistant to most drilling fluids including Brine

- Suitable for Ceramic and Zirconia liners

Shorty

- High-pressure 7500psi application

- Rated Temp: 240° F [115° C]

- Dual durometer lip seal construction

- High wear and long life lip seal in with well-aligned rods

- Resistant to most drilling fluids including Brine

- Suitable for Ceramic and Zirconia liners

Highlander

- High-pressure 7500psi application

- Rated Temp: 220° F [104° C]

- Dual durometer bonded solid-body construction

- Resistant to most drilling fluids including Brine

- Suitable for Ceramic and Zirconia liners

Highlander HT

- High-pressure 7500psi application

- Temp resistance: 300° F [148° C]

- Dual durometer bonded solid-body construction

- Resistant to most drilling fluids including Brine

- Suitable for Ceramic and Zirconia liners

Black Max

- High-pressure 7500psi application

- Rated Temp: 240° F [115° C]

- Single durometer rubber lip seal construction

- Accommodates small misalignments of the rod systems

- Highly resistant to water and brine drilling fluids

General Service Rubber Flex. Lip

- 5000psi application

- Rated Temp: 200° F [93° C]

- Single durometer rubber piston

- Highly resistant to water and brine drilling fluids

Replaceable Rubber Fabric Backing Solid Body

- High-pressure 7500psi application

- Rated Temp: 200° F [93° C]

- Replaceable rubber element

- Single durometer rubber solid-body construction

- Highly resistant to water and brine drilling fluids

Valves & Seats

FET manufactures a full range of drilling rig mud pump valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Full Open

The full open style performs well in extreme conditions such as high-solids and high-pressure applications. This valve is based on the roughneck design and is fully interchangeable with other major manufacturers. The improvement to the original design is based on minor dimensional changes on the valve insert groove to accommodate a better fit between the valve and the valve insert.

Full Open High Temp.

The valve insert material is rated for high-temperature applications and should be used at temperatures above 180°F, up to a maximum of 240°F. It distinguishes itself from other manufactured high-temp valves by maintaining critical properties for abrasion resistance and

tear resistance.

Full Open Extra High Temp.

The valve insert material is rated for high-temperature applications and should be used at temperatures above 300°F. It distinguishes itself from other manufactured high-temp valves by maintaining critical properties for abrasion resistance and tear resistance.

4-Web Center Guided

A well-proven design that allows for easy replacement of the valve insert in the field. The valve is designed for use in low-solids applications and pressures up to 6,000 psi. This valve does interchange with other major manufacturers. The 4-web valve and seat are based on an existing design known as the mud king or supreme style valve.

4-Web Center Guided High Temp.

Designed for use in low-solids applications, and pressures up to 6,000 psi. Designed for easy replacement of the valve insert in the field with a split plate/retainer system. This style has over 50 years of proven field service. It does include an option for a rubber insert which allows for high-temperature applications up to 240°F.

Double Angle 3-Web Center Guided

The double-angle o-ring has proven to be the most well-designed valve and seat on the market today. The valve is designed with a tough one-piece body and a “double angle” 55° seal contact surface, which maintains cylinder priming during shutdown. The configuration gives maximum containment of the insert with minimal material. This style performs well in extreme service conditions such as high-pressure and high-solids applications. This design utilizes a snap-on insert.

Double Angle 3-Web Center Guided High Temp.

This style performs well in extreme service conditions such as high temperature, high-pressure and high-solids applications. The double-angle o-ring has proven to be the most well-designed valve and seat on the market today. The valve is designed with a tough one piece body and a “double angle” 55° seal contact surface, which maintains cylinder priming during shut down. The configuration gives maximum containment of the insert with minimal material. This design utilizes a snap-on insert.

Replaceable 3-Web Center Guided

This style performs well in lower-pressure applications, up to 5,000 psi. The center-guided design with a single stem at both the bottom and top of the valve allows for an excellent alignment when opening and closing during operation.

Mud Pump Liners

FET liners are designed to provide unmatched performance and durability in the most severe drilling conditions on the planet. Our liner hulls are manufactured using high-grade carbon steel forging to withstand the uplift forces present during mud pump operations. We then install our proprietary Chrome, Ceramic, or Zirconia sleeves into the hull using a shrink-fit process. All our liners utilize a high-pressure lip design on the sleeve to prevent slippage during high-pressure operations.

Steel Liners

- 26% chrome steel sleeve

- Bore hardness of 60-64 HRC [695-789HV]

- Rated up to 7500psi working pressure

- Service life of up to 1,000 pumping hours

- Surface Finish ID 16-20 RMS

Ceramic Liners

- High-density Ceramic sleeve

- Minimum bore hardness of 74 HRC [1300HV]

- Rated up to 7500psi working pressure

- Service life of up to 3,000 pumping hours

- Reduced liner and piston wear

- Surface Finish ID of 8 RMS

- Liner ID can be re-honed to +0.005 for repeated use

Zirconia Liners

- Zirconia sleeve

- Minimum bore hardness of 63 HRC [763 HV]

- Rated up to 7500psi working pressure

- Service life of up to 5,000 pumping hours

- Reduced liner and piston wear

- Liner ID can be re-honed to +0.005 for repeated use

- Surface Finish ID of 4-8 RMS

Discharge & Suction Manifolds

Forum manufactures discharge and suction manifolds for most mud pumps in the industry today. With options for 5,000 psi and 7,500 psi, we also offer full-custom builds tailored to your application.

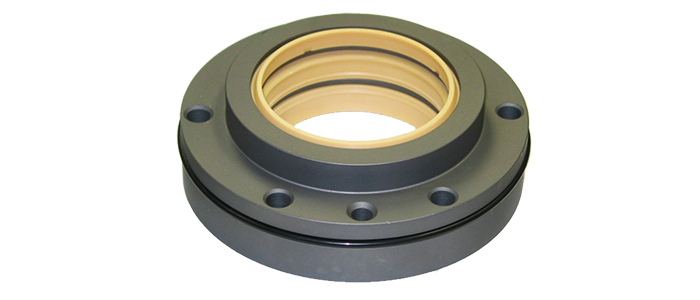

Press Pony Rod Sealing System

Drilling fluid contamination in the power end of your mud pump can lead to costly repairs. Forum’s Pony Rod Enhanced Sealing System (PRESS™) incorporates a patented polymer with four sealing surfaces and an excluder wiper to provide a superior seal. Case studies have shown up to four times longer life than traditional pony rod seals, lowering operating costs and preventing expensive failures.

- Abrasion resistant

- Superior memory and elasticity

- Dimensionally stable to 275 degrees F

- Four sealing surfaces

- Mistake-proof installation