Authors: Hossein Izadi, Javad Sadri, Fateme Hormozzade, Vahidoddin Fattahpour

Intelligent mineral segmentation in thin section images of rocks still remains a challenging task in modern computational mineralogy. The objective of the paper is segmenting minerals in geological thin section’s images with special attention on altered mineral segmentation. In this paper, an efficient incremental-dynamic clustering algorithm is developed for segmentation of minerals in thin sections containing altered and non-altered minerals. In the clustering algorithm, there is no need for determining the number of clusters (minerals) existed in thin section images, and also it is able to deal with color changing and non-evident boundaries in altered minerals. We have solved two main existing limitations: segmentation of mineral pixels that are frequently labeled as background pixels, and segmentation of thin sections containing altered minerals. Moreover, we created an open database (Alborz Mineralogical Database), as a benchmark database in computational geosciences regarding image studies of mineral. The proposed method is validated based on the results provided by the segmentation maps, and experimental results indicate that the proposed method is very efficient and outperforms previous segmentation methods for altered minerals in thin section images. The proposed method can be applied in mining engineering, rock mechanics engineering, geotechnique engineering, mineralogy, petrography, and applications such as NASA’s Mars Rover Explorations (MRE).

Download paper

Authors: Lu Gong, Ling Zhang, Li Xiang, Jiawen Zhang, Vahidoddin Fattahpour, Mahdi Mamoudi, Morteza Roostaei, Brent Fermaniuk, Jing-Li Luo, and Hongbo Zeng

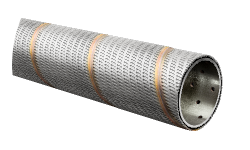

Surface interactions between emulsion drops and substrate surfaces play an important role in many phenomena in industrial processes, such as fouling issues in oil production. Investigating the interaction forces between the water-in-oil emulsion drops with interfacially adsorbed asphaltenes and various substrates is of fundamental and practical importance in understanding the fouling mechanisms and developing efficient antifouling strategies. In this work, the surface interactions between water drops with asphaltenes and Fe substrates with or without an electroless nickel–phosphorus (EN) coating in organic media have been directly quantified using the atomic force microscope drop probe technique. The effects of asphaltene concentration, organic solvent type, aging time, contact time, and loading force were investigated. The results demonstrated that the adhesion between water drops and the substrates was enhanced with higher asphaltene concentration, better organic solvent to asphaltenes, longer aging time, longer contact time, and stronger loading force, which was due to the growing amount and conformational change of asphaltenes adsorbed at the water/oil interface. Meanwhile, the adhesion between the water drop and the EN substrate was much weaker than that with the Fe substrate. The bulk fouling tests also showed that EN coating had a very good antifouling performance, which was in consistence with the force measurement results. Our work sheds light on the fundamental understanding of emulsion-related fouling mechanisms in the oil industry and provides useful information for developing new coatings with antifouling performances.

Download paper

Authors: Chong Sun, Jiankuan Li, Vahidoddin Fattahpour, Morteza Roostaei, Mahdi Mahmoudi, Hongbo Zeng, Jing-Li Luo

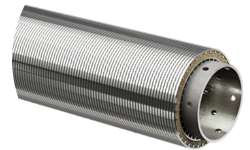

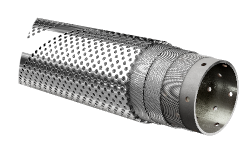

The erosion-enhanced corrosion behavior of electroless Ni–P coating was investigated by single particle impingement coupled with in-situ electrochemical measurements. The transient anodic dissolution of Ni–P coating induced by the single particle impingement is enhanced with the rising impact velocity, followed by a rapid repassivation that obeys a bi-exponential decaying law. The coating demonstrates a good erosion-corrosion resistance due to its strong capability of repassivation that is scarcely affected by the changing hydrodynamics under the test conditions. The erosion-enhanced corrosion rate of Ni–P coating in flowing slurry is well predicted based on the repassivation kinetic parameters determined from single particle impingement.

Download paper

Authors: Zhengbin Wang, Chong Sun, Linlin Li, Morteza Roostaei, Vahidoddin Fattahpour, Mahdi Mahmoudi, Hongbo Zeng, Yugui Zheng, Jing-Li Luo

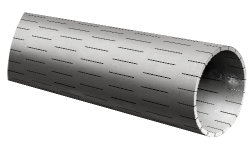

Repassivation time (tre) is a significant parameter when evaluating the repassivation property of material. Herein, we propose a new method to obtain tre by first theoretically unifying the repassivation current–time (i(t)) function for common film growth models, subsequently simplifying the unified i(t) function based on single particle impingement data, then deriving the completed repassivation current expression corresponding to tre using mathematical approximation methods, and finally verifying this method via comparing the obtained tre of three materials. The newly proposed method is reliable, universal and simple to compare repassivation properties of different materials without curve fitting and considering film growth mechanism.

Download paper