On pump downs and other pressure jobs, the wellhead is equipped with a lubricator (6, 8, and 10) and flow tubes (4) to maintain well control when lowering the wireline tools and cable from atmospheric pressure into the well, which can be at several thousands of pounds of pressure. Bringing the wellbore and the lubricator to the same pressure is known as “equalization.” There have been several cable failures where either the conductor melted or, in more severe cases, the cable parted during the equalization process. The failures have typically occurred one to two feet above the cable head. Wireline subjected to this failure mode will appear burned, and the armor wires may become brittle.

On pump downs and other pressure jobs, the wellhead is equipped with a lubricator (6, 8, and 10) and flow tubes (4) to maintain well control when lowering the wireline tools and cable from atmospheric pressure into the well, which can be at several thousands of pounds of pressure. Bringing the wellbore and the lubricator to the same pressure is known as “equalization.” There have been several cable failures where either the conductor melted or, in more severe cases, the cable parted during the equalization process. The failures have typically occurred one to two feet above the cable head. Wireline subjected to this failure mode will appear burned, and the armor wires may become brittle.

How can this happen? Is it possible for enough heat to be created in the lubricator to melt the conductor and physically change the steel properties, causing cable failure, even with a bottom-hole temperature of less than 400°F? The answer is “yes” if the equalization process is performed too rapidly. Let’s look at how this occurs.

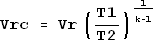

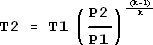

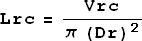

When the lubricator is filled very rapidly, the air inside the lubricator will compress from atmospheric pressure (15 psi) to wellbore pressure (say 3,500 psi) extremely rapidly because there is very little room past the flow tubes for the gas to escape. This rapid compression causes an extreme increase in air temperature because the time frame does not permit significant heat loss. The formula to calculate this “adiabatic” (zero heat loss) temperature rise is as follows:

In practice, you could never compress the air fast enough to keep some heat from being lost, but this calculation sets an upper limit. Using the values above, the calculated temperature of the air after an adiabatic compression would be 1,200°F. If these high temperatures seem unrealistic, consider putting your hand on an air compressor. Even a 150 psi air compressor gets quite hot.

Consider a 26-foot riser with an ID of 5 inches. Inside the riser is a 24-foot tool that is 3.125 inches in diameter. The volume, Vr, filled with air at 15 psia, would be 16,000 cubic inches.

![]()

The volume after adiabatic compression, Vrc, according to the formulae to the right, would be only 500 cubic inches.

The length of the column of compressed air in the riser, Lrc, is 6 inches.

The calculations above show that the length of compressed air is approximately 6 inches. If the tool is at the bottom of the riser, there would be about 2 feet of cable above the tool and below the grease head.

The 6 inches just below the grease head is where the air would be, and at this point, the temperatures could approach 1,200°F. The insulating material would melt quickly and possibly alter the metallurgy of the steel, causing the wire to become brittle. The rapid gas flow at the same location may result in the severing of the wireline.

What can we do to mitigate the problem?

Although we have spoken of temperature, the real culprit is how much heat energy is available to damage the cable.

Q = Heat Generated = Wa(cp)(T2–T1) = (9.25)(0.24)(1235–75) = 2575 BTU

The amount of heat available at this high temperature to damage the cable increases directly with the height of the air column and the square of the diameter of the lubricator. In essence, the amount of air retained after compression. Also, remember that the theoretically calculated maximum temperature is based on the condition that the pressure change is so rapid that there is not enough time for the air to escape through the packer and flow tubes or for heat to conduct away by the casing. In the real world, some air will escape, and some heat will conduct away, but if the valve opens fast enough, you can reach temperatures high enough to melt cable insulation and affect the armor metal properties.

In practice, to avoid this problem, consider the following points:

- Rapidly filling the lubricator will result in a condition where the air has nowhere to go and thus compresses, resulting in extreme temperatures and high heat energy, which can damage the cable permanently.

- The more air in the lubricator can generate more heat.

- Filling the lubricator with fluid before equalizing will mitigate much of the air and, therefore, most of the energy to cause damage

- Installing a bypass valve just below the flow tubes allows the air to escape much faster.