Gas slugs develop under numerous production conditions resulting in various circumstances including changes in reservoir conditions, changes in production strategy (EOR/IOR) and changes in production rates. Despite the situation, slugging is one of the most widely faced issues in the oil and gas industry. This is especially true for unconventional wells produced with artificial lift technologies including electric submersible pumps (ESPs) that can experience significant increases in operation costs and capital expenses due to lost production, damaged equipment and inefficient operational envelopes which in turn lead to differed incremental production that could be captured in an optimized ESP system.

The best solution is prevention: disrupting gas slugs before they disrupt production.

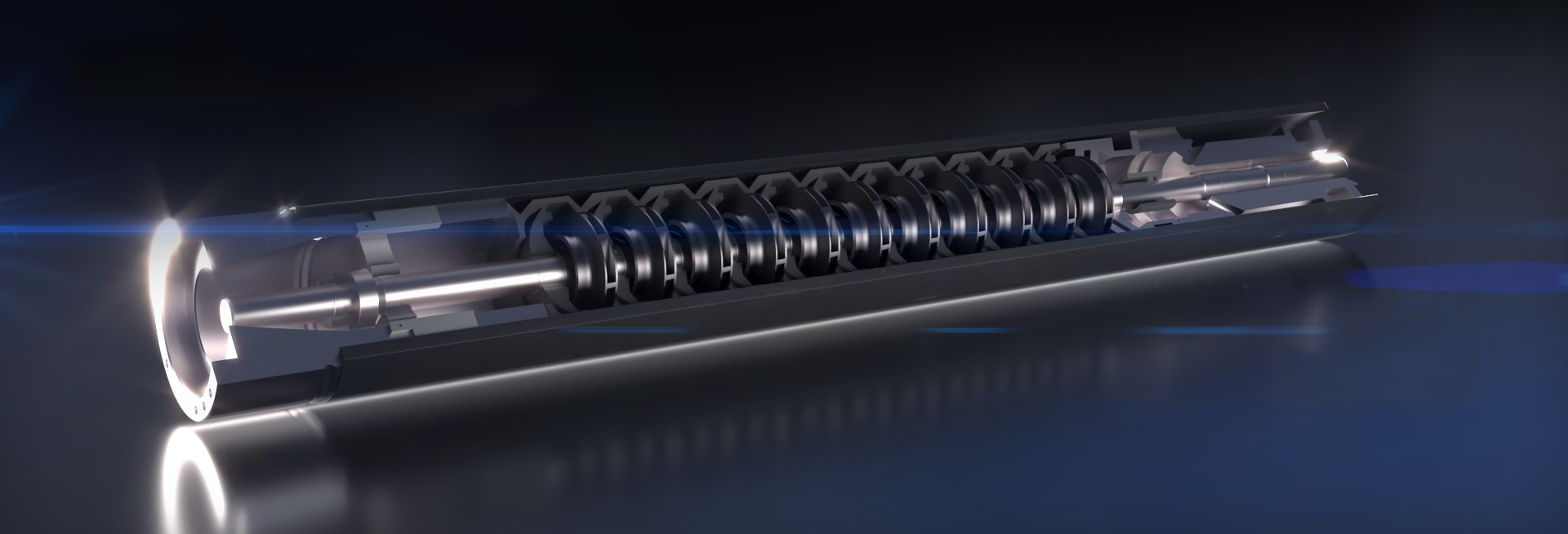

FET presents the patent-pending Forum GasGuard®, which breaks down/infuses gas slugs before they reach an ESP system, creating an uninterrupted flow of liquid through the pump and eliminating slug flow. The result is a more consolidated, continuous production stream with higher liquid content leading to increased motor cooling and improved ESP performance with fewer shutdowns. With a streamlined, simplified design, FET’s GasGuard represents a new paradigm of protection against unpredictable gas slugs.

Our GasGuard® is part of FET’s extensive Multilift Solutions suite of artificial lift solutions.

Applications

- Unconventional wells

- Steam-assisted gravity drainage wells

- Wells with severe gas slugging

- ESPs, rod pumps, progressing cavity pumps, hydraulic piston/linear pumps

Features

- No moving parts

- Modular design for extreme applications

- Compatible with chemical injection centralizer, SandGuard™ and Cyclone™ products

Benefits

- Installs and pulls easily using the production string

- Improves efficiency of ESP motor cooling

- Reduces equipment costs with simple design

- Disrupts gas slugs before they reach the pump intake

- Improves pump runtime and performance

- Helps prevent pump shutdowns caused by gas lock

- Work in conjunction with and can reduce the need for expensive ESP gas handling devices that are still susceptible to gas lock