Design and Manufacturing Details

Manufactured & Tested to Meet Industry Standards

The Quality Advantage

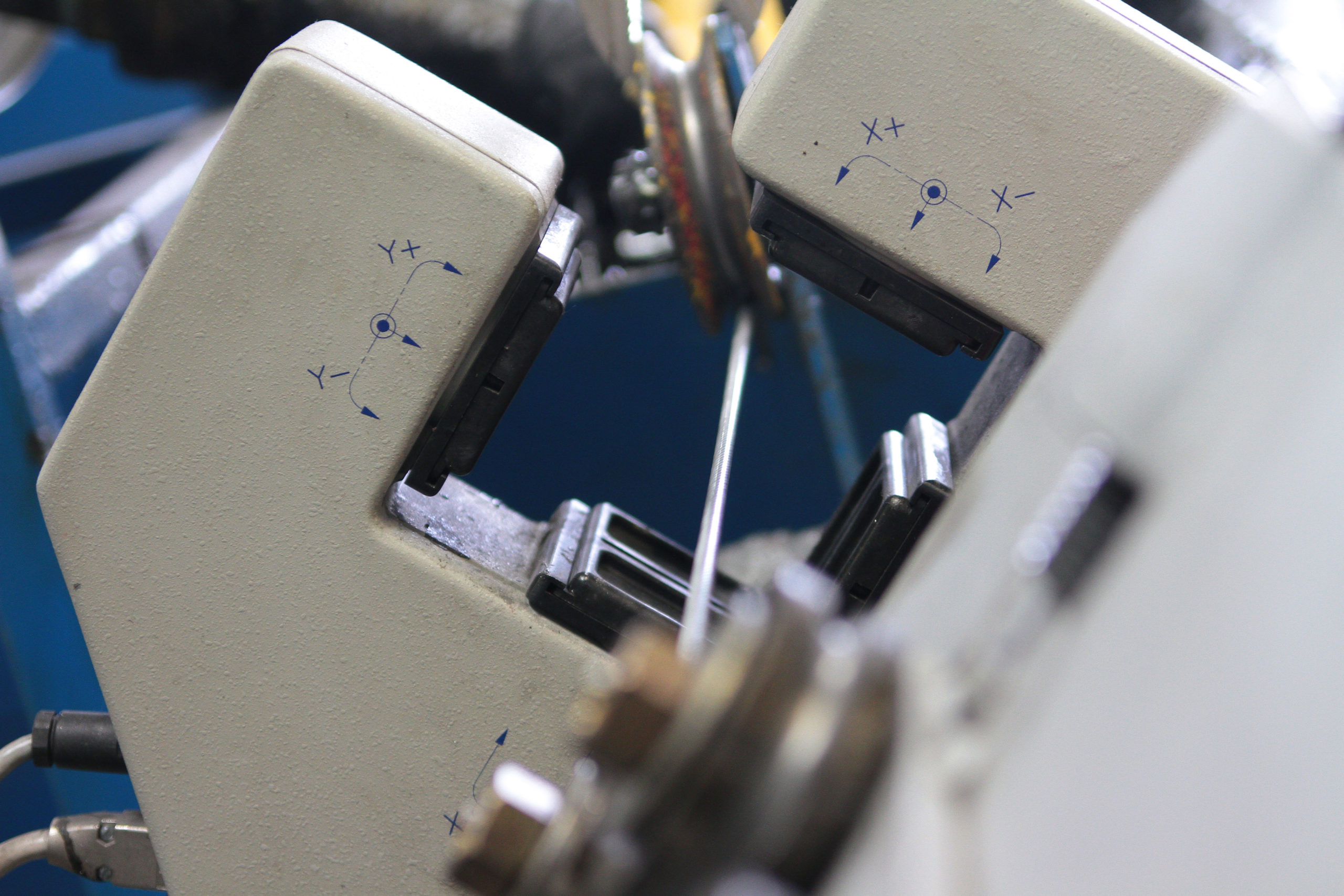

- Unique to Quality Wireline is our custom-designed “infinite lay” armoring process, which allows us to optimize armor coverage and ensure the highest-quality cable.

- Our leading-edge high-speed Rewinder, coupled with our rigorous quality control on wire supply, eliminates most potential quality problems related to wire.

General

- The cable’s temperature rating is based on a ‘normal tension and temperature profile.’ This profile refers to situations where cable tension and temperature increase with depth, with maximum temperature at the bottom of the borehole.

- All cable diameters and wire diameters shown in the catalog are nominal.

Electrical

- All electrical conductors are water-blocked using a process that precisely controls the amount of blocking material applied to the conductor. This process effectively minimizes the effects of fluid or gas migration through the conductor.

- All extruded conductors maintain a 95%-100% concentricity.

- State-of-the-art non-contact measuring systems for diameter, ovality, and concentricity provide real-time quality control data, enabling a fully closed-loop control system to ensure optimum conductor quality. Electronic records are archived with quality control.

- Repair to the electrical conductor insulation is prohibited if the copper conductor is exposed.

- Electrical conductor resistance and insulation are corrected to 20° C/ 68° F.

- Electrical resistance and capacitance values in the catalog are nominal.

Cable & Breaking Strength

- A direct relationship exists between the wire’s tensile strength and the cable’s breaking strength, specified on individual cable specification sheets.

- The cable breaking strength is tested and guaranteed, with no cable end rotation.

- The cable breaking strength is a calculated value with ends fixed.

- The cable working load on standard cables extends to 60% of the rated cable breaking strength.

Armor

- You can select several armor types depending on the application and well conditions. We armor our standard cables with galvanized improved plow steel (GIPS) wire and our high-strength cables with extra galvanized improved plow steel (XGIPS). We also armor our cables for corrosive environments with corrosive-resistant nickel alloy materials, including S75, S77, and MP-35N.

- TCI (Torque Compression Inhibitor) is applied between armor layers to minimize fluid migration and friction between the layers during the cable’s initial runs until seasoning occurs.

- The cable armor is coated with protective grease to maintain armor surface quality during shipping, handling, and storage.

- We preform all armor wires in the manufacturing process with an average value of 77% (+/—2.5%).

- Butt welds are NOT allowed in the outer armoring process.

Quality Wireline & Cable Catalog

Our Quality Wireline & Cable catalog lets customers view a complete summary of our product options and information about FET’s Cable School and Service Center resources.