Learn Best Practices for Conventional Wireline Cables

Our team of wireline experts encourage all customers operating conventional cable to follow our recommended best practices.

- Ensure the drum’s integrity prior to any installation.

- Always use a Certified Service Center for installation.

- Season the cable for first 30 runs.

- Allow the cable to rotate on the vertical zone of the cable for at least five minutes every 1,000 – 2,000 feet.

- For new cables, stick to the 80/120 tension rule after the cable is seasoned 50/150.

- The tension going into the well should never be less than 80% of line weight plus tool weight.

- The tension coming out of the well should never exceed 120% of the line weight, tool weight, and any drag from the well due to friction that would increase tensions.

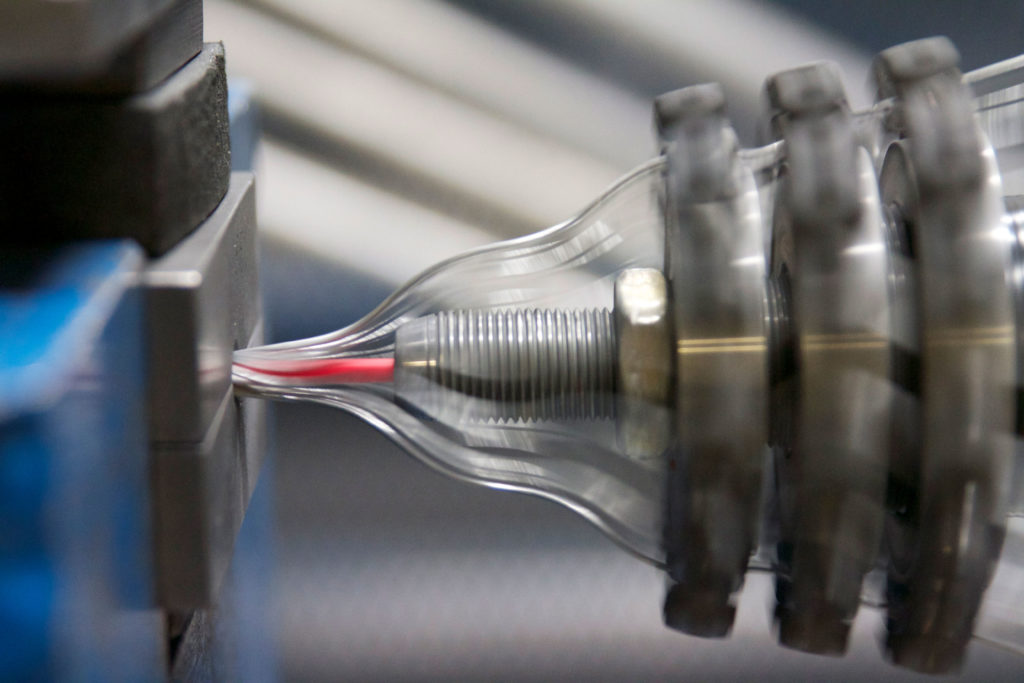

- Use 0.004” to 0.006” clearance flow tubes.

- Periodically, check cable for:

- Kinks or shiny spots in cable and mark or note location.

- Loose armor or torque on the cable.

- Check the cable electrically pre-job and post-job.

- Inspect the rope socket components for excessive wear or scaring of cone and washer.

- Have the cable serviced if you experience any abnormal high tensions or any great loss of tension while on job.

- Ideally, the unit should be at least 25 feet from the bottom sheave for every 12” of width on your cable drum.

- Use the proper sheaves size for each cable.

- When re-heading, check cable for embrittlement.

- Inspect for cross armor wires while re-heading through flow tubes.

- When possible, use swivels to help achieve the proper rotation.

- Bring cable to a service center for retorquing after 80 to 100 runs.

- Keep an accurate logbook and note all things that you see. This will help the service centers and manufacturer better service your cable for longer life and to resolve any potential cable issues.