Corrosion Protection with Chemical Injection Centralizer

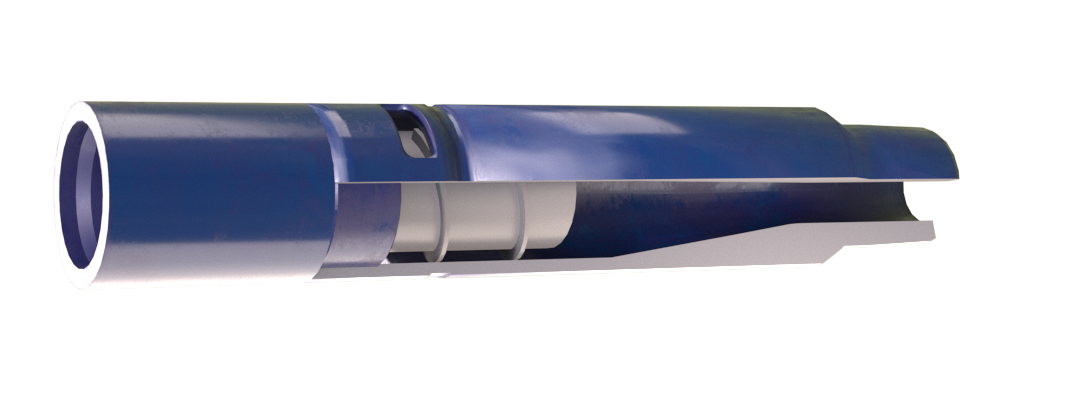

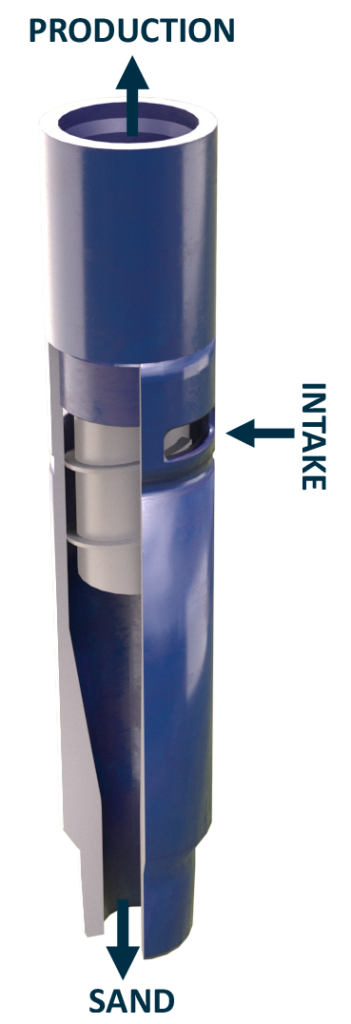

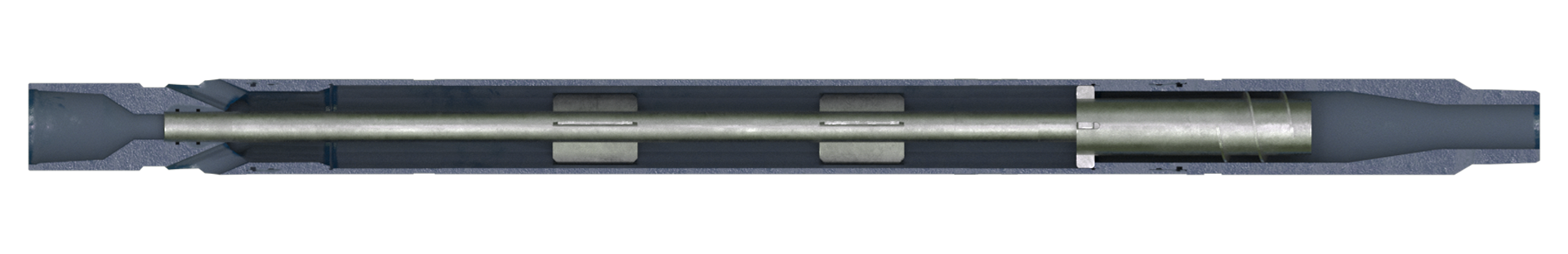

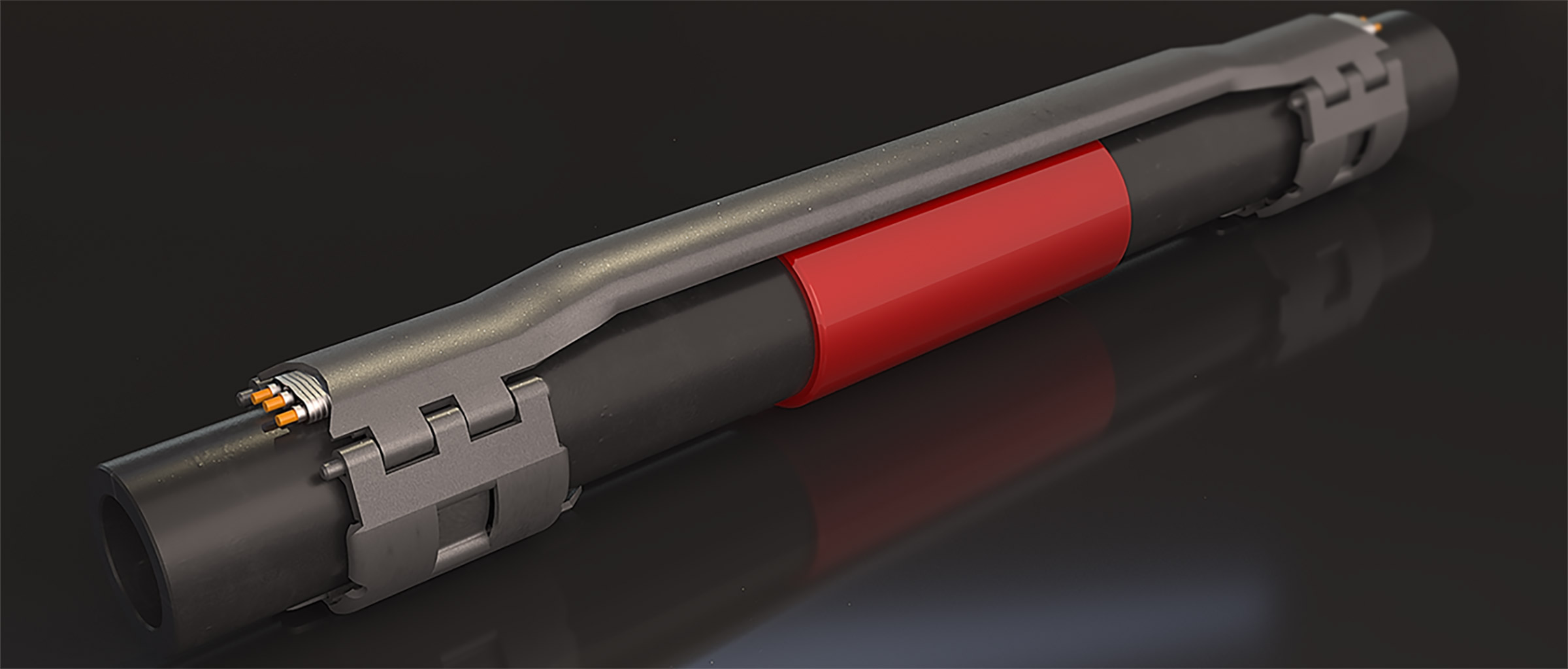

FET’s Chemical Injection Centralizer, part of our Multilift artificial lift solutions portfolio, offers a more innovative, more efficient approach. Installed below the ESP motor, it functions as both a centralizer and a chemical injection system, delivering uniform 360° dispersion for consistent chemical treatment and enhanced ESP performance.

By ensuring even spacing between the motor and casing, the centralizer promotes balanced fluid flow, preventing hotspots and improving motor cooling. This dual functionality not only protects your ESP system but also boosts its reliability and uptime.

FET’s chemical injection centralizers are part of our extensive Multilift artificial lift solutions catalog.

Key Benefits

- Optimized Chemical Treatment: Uniform 360° dispersion minimizes corrosion risks associated with uneven injection.

- Enhanced ESP Cooling: Equal flow paths improve thermal regulation around the motor.

- Improved System Reliability: Reduces the chance of damage during installation and operation.

- Increased Uptime: Proper centralization enhances ESP performance and longevity.

- Operational Efficiency: Minimizes chemical waste and the risk of emulsion-related issues.

Features

- Compatible with all downhole ESP systems

- Dual chemical injection line connections

- Six nozzles for full 360° spray coverage

- Integrated check valve system

- Customizable tubing sizes and thread types

- Minimum injection pressure: 500 psi

- Flow rates: ¼-inch line – up to 3.5 GPM; ⅜-inch line – up to 7 GPM

- Withstands differential back pressure up to 5,000 psi

Applications

- Casing sizes of 5 inches or larger

- Vertical, deviated, and horizontal wells

- ESP installations inside liner applications

- Point-of-departure chemical injection scenarios

Discover how FET’s Chemical Injection Centralizer can help you achieve more effective corrosion control while improving ESP system performance and operational efficiency.