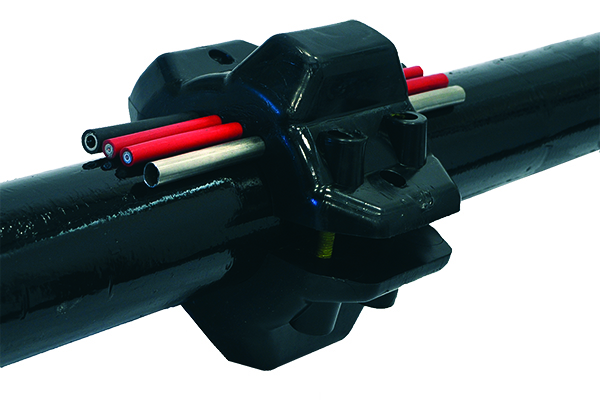

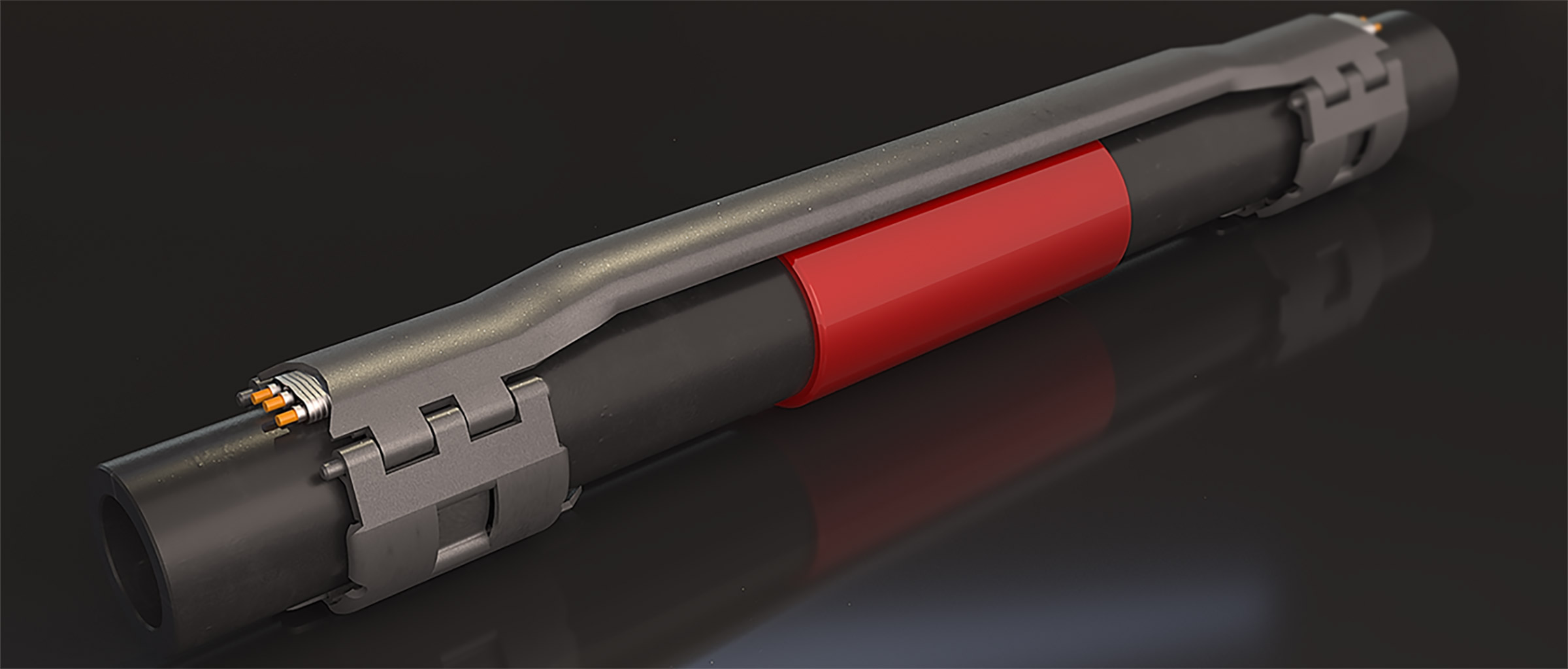

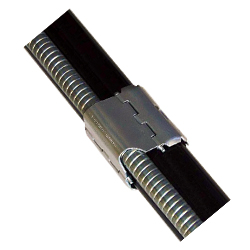

Centralizing tubing and work string of deepwater completions is critical for preventing damage caused by riser contact. Manufactured from a DuPont™-engineered material, our thermoplastic centralizers are injection molded and designed for maximum durability and performance. These safe, stable and reusable centralizers offer a unique design including custom slots for each control line and a self-contained wrap that holds all locking parts securely within the assembly.

Forum’s thermoplastic centralizers are part of our Cannon Services product line and extensive MultiLift artificial lift solutions catalog.

Benefits

- Protects tubing from costly damage by preventing contact with riser.

- Installs quickly to reduce workover time and cost.

- Offers high reusability, increasing cost savings on well recompletions.

Features

- Custom designed for tubing, riser and control line sizes

- Injection molded for optimum uniformity and quality

- Different injection molding colors for color coding

- Single-piece design for quick installation

- Excellent impact and wear resistance

Applications

- Deepwater risers