Coiled Line Pipe provides a better, faster, and more cost-efficient way to install steel line pipe for CO2 injection system flowlines.

Project Overview

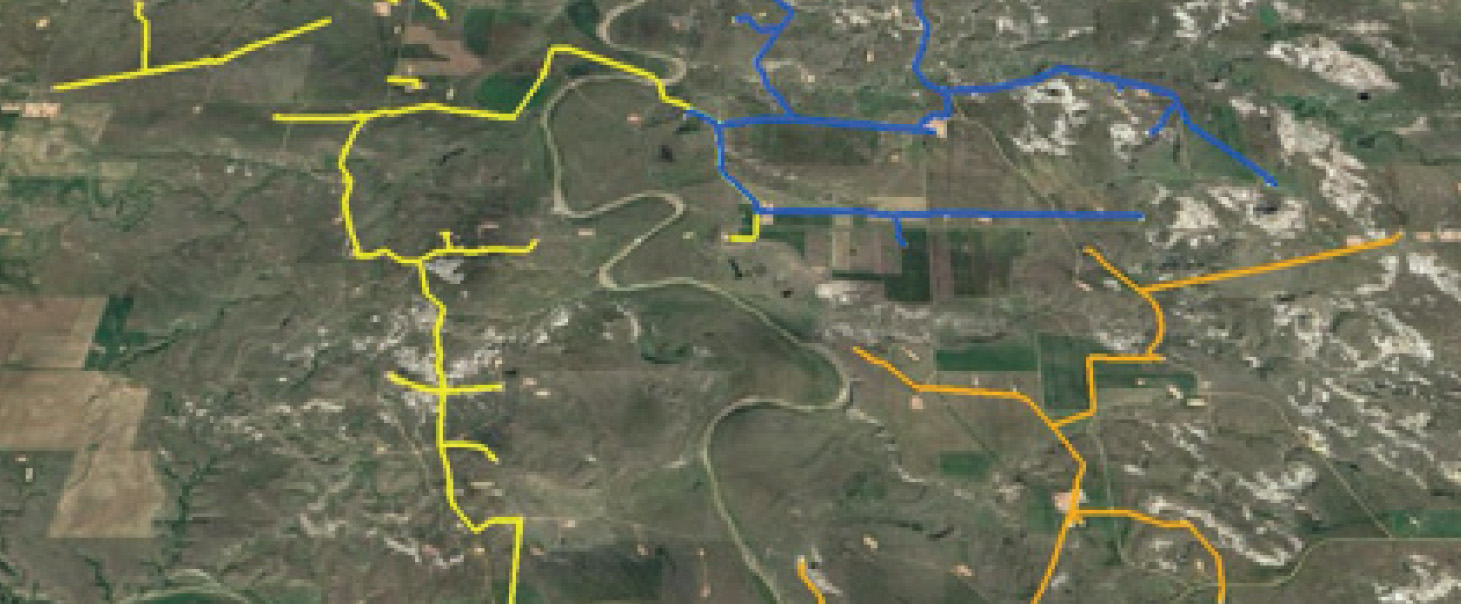

A large, publicly traded, independent oil and gas company, has an expansive midstream multiphase field development that requires a safe, quick, and cost-efficient steel flowline installation. The pipeline system has several road & pipeline crossings, a directionally drilled bore river crossing, and multiple mobilizations. Coiled Line Pipe has been chosen as the preferred solution that can provide the greatest cost benefit, highest safety potential and improved product performance as compared to the usual stick steel pipe and other non-steel flowline alternatives.

Project Highlights

- Large gathering system to connect three (3) different units.

- Traversing several sensitive BLM land areas with reduced impact using Coiled Line Pipe

- 47 injection wells

- A river crossing to be accomplished with HDD

- Numerous road crossings

- Global Tubing is prepared to fulfill the needs of the customer by supplying 140,000 ft of Coiled Line Pipe on 60 spools in staggered, on demand, deliveries to a centrally located pipe yards to be

dispersed to specific sites, as needed. - The Coiled Line Pipe installation from unloading to ditch is 3 times faster than stick steel pipe, require 65% less man hours, and has a reduced impact to sensitive areas due to more limited right

of way requirements.

Conclusion

By using Coiled Line Pipe, every client can enjoy the peace of mind that only steel pipe’s long history and specification compliance can provide and combine it with the cost savings of a spool-able pipeline. Cost Savings over the steel pipe installation will make large projects like this one more feasible, even in a challenging market and economy.

PROJECT

New CO2 Injection System Construction

LOCATION

Baker, Montana

APPLICATION

Gas Injection Flowlines

MATERIAL SPECIFICATION

4″ Nominal OD (4.5″ Actual OD),

Schedule 40 (0.237″ wall thickness)

3″ Nominal OD (3.5″ Actual OD),

Schedule 40 (0.216″ wall thickness)

2″ Nominal OD (2.375″ Actual OD),

Schedule 40 (0.154″ wall thickness)

All X52C Coiled Line Pipe with 3 Layer Polypropylene Coating

LENGTH

4″ S/40 – 35,000 feet

3″ S/40 – 57,000 feet

2″ S/40 – 47,000 feet