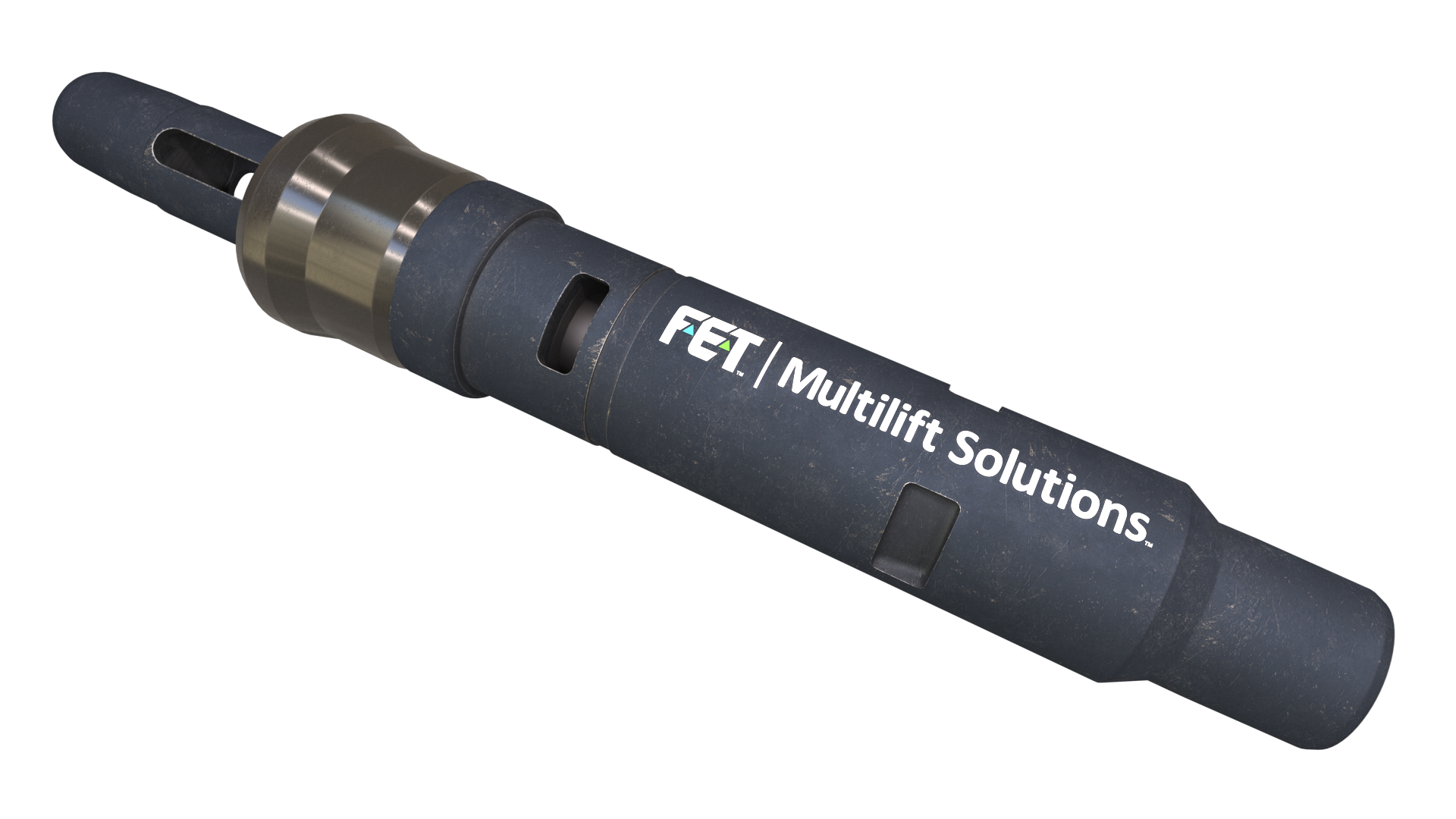

ABS MagneGuard™

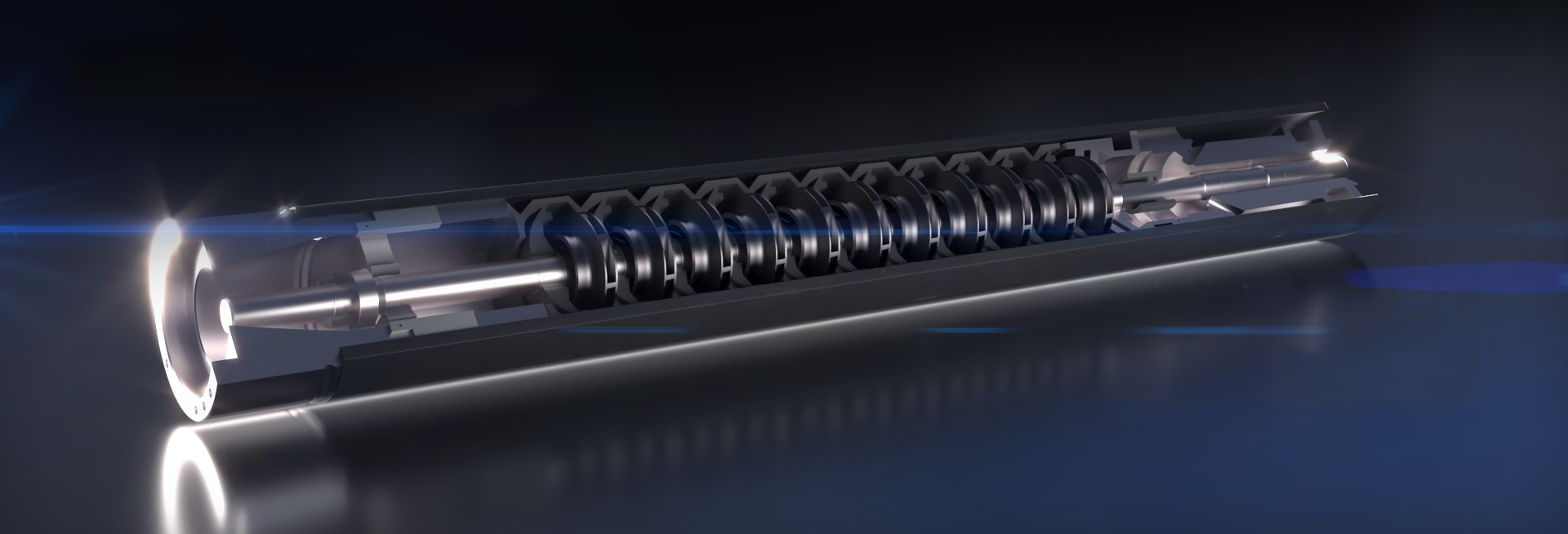

While Permanent Magnet Motor-Driven ESPs are widely used for fluid extraction, they also pose a significant risk of electric shock to field personnel. The FET Multilift Solutions ABS MagneGuard™ provides essential protection against this hazard, enabling the safe operation of PMM-driven ESP systems.

PM motors generate significant voltage up the cable when the motor shaft is rotated by hydraulic action. This exposes personnel to serious dangers when working on exposed cables and switchgear during workovers and maintenance. Tragically, field personnel handling PM motors on site have suffered severe electric shock and even death.

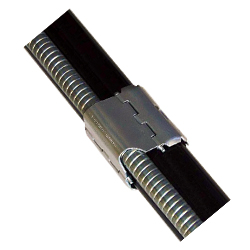

Until now, the most common mitigation method for electric shock risks is shorting out the cable at the surface – leading to many vulnerable risks during installation and pulling. The ABS MagneGuard automatically provides a reliable and efficient elimination of all risk, without the need for manual interventions or special procedures.

Features

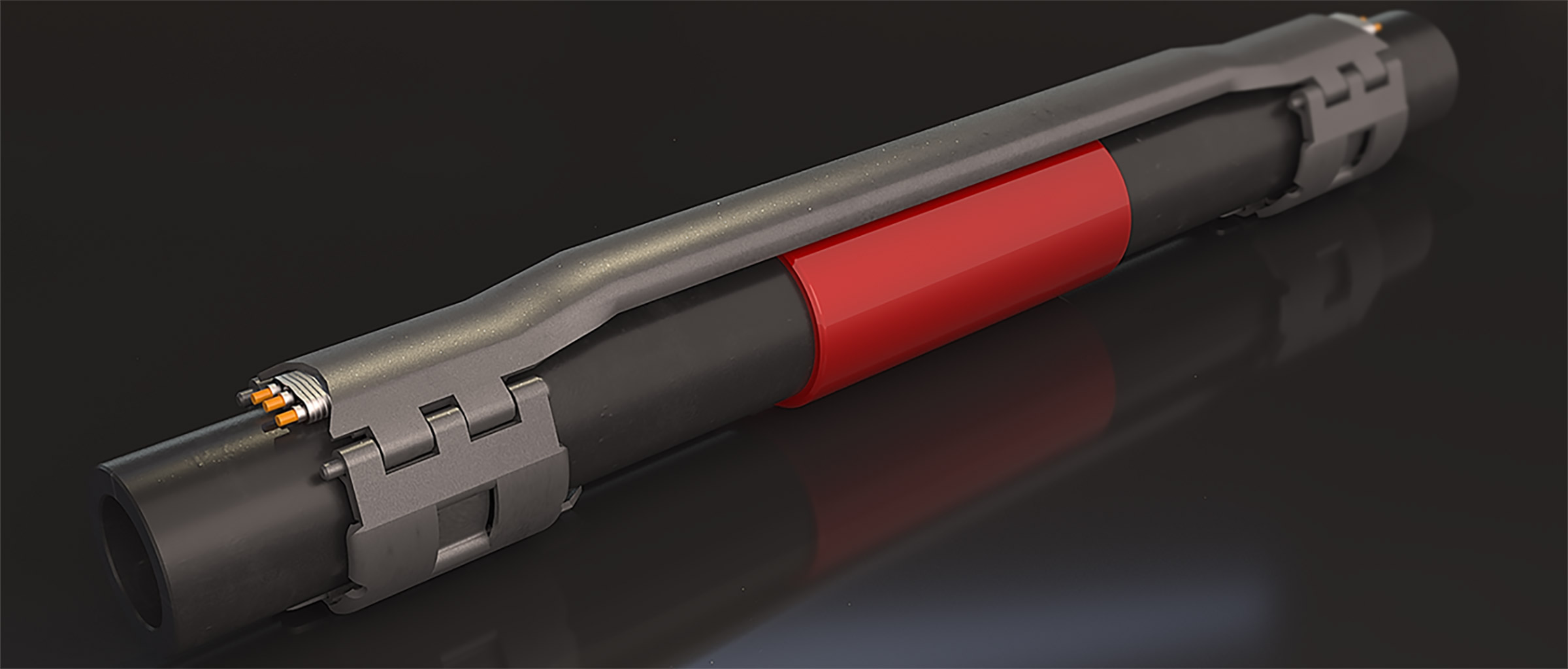

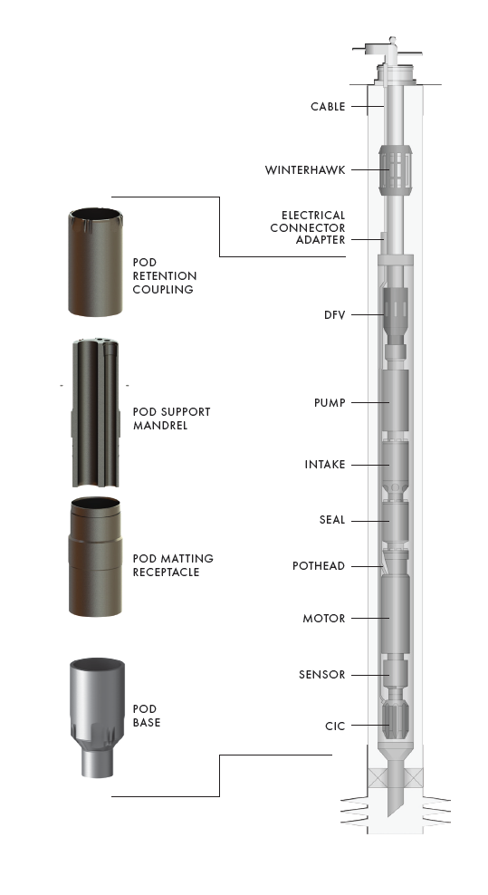

- Regardless of the ESP manufacturer, ABS MagneGuard adapts to all ESP configurations and manufacturers providing ease of use and peace of mind when installing any permanent magnet motor.

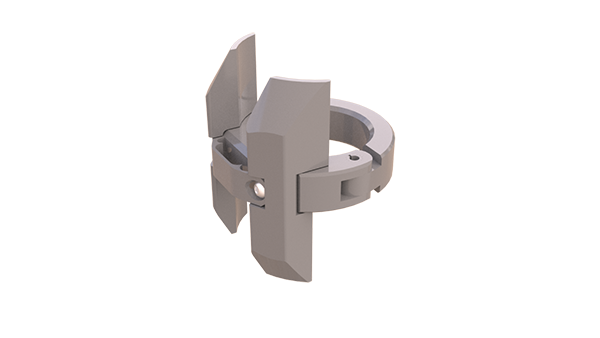

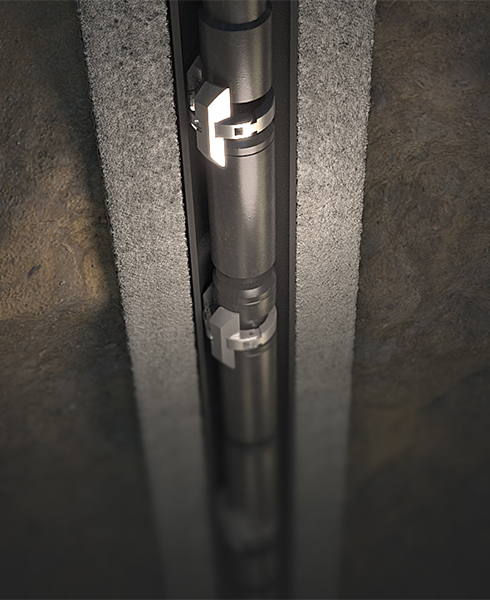

- Installed on top of the pump head and doesn’t interfere with the ESP system.

- Prevents any rotation of the pump and motor shafts caused by the passage of fluid through the pump when the motor is deactivated, such as during RIH and fallback situations.

Benefits

- Personnel Safety: Removes human element doubt by automatically eliminating risk to personnel.

- Cost savings: Negates the need for third-party services on site, also minimizing rig time needed for special operations and procedures.

- Simplicity: Bolt on to any manufacturer’s pump

- Enhanced Operations: Removes the most critical barrier to universal adoption of PMMs.