Brand: Multilift Solutions

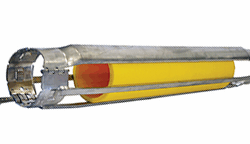

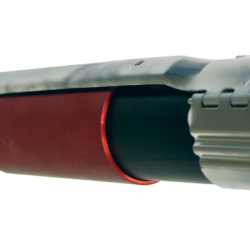

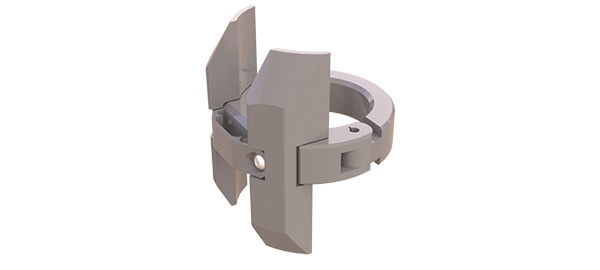

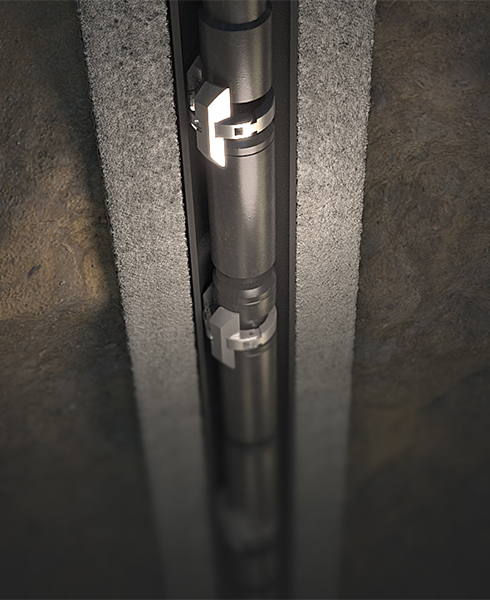

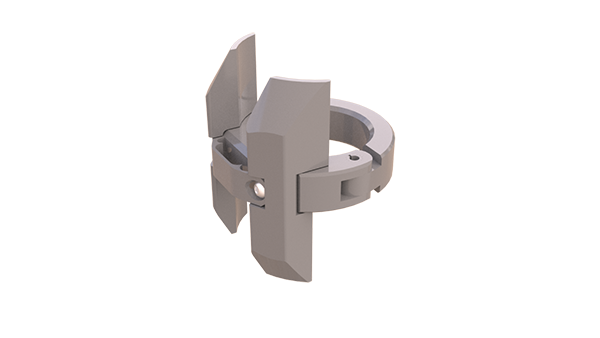

Thermoplastic Centralizer

Thermoplastic Centralizer: Reliable Protection for Deepwater Completions

In deepwater operations, protecting tubing and work string from riser contact is essential to avoid costly damage. Our thermoplastic centralizers, crafted from advanced DuPont™-engineered materials, are built to meet this challenge with strength and precision.

Each centralizer is injection molded for consistent quality and features a durable, single-piece design that simplifies installation and enhances performance. With custom slots for control lines and a secure, self-contained wrap, these centralizers deliver unmatched stability and reusability in demanding offshore environments.

Part of FET’s Cannon Services product line and our comprehensive MultiLift artificial lift solutions, these centralizers are engineered to perform again and again.

Key Benefits

- Protects tubing from riser contact, reducing the risk of expensive repairs.

- Speeds up installation, cutting down workover time and operational costs.

- Reusable design supports cost-effective well recompletions.

Features

- Tailored to fit specific tubing, riser, and control line dimensions

- Precision injection molding ensures uniformity and strength

- Available in multiple colors for easy visual identification

- Single-piece construction for fast, hassle-free installation

- Exceptional impact and wear resistance

Ideal For

- Deepwater riser applications where durability and reliability are critical

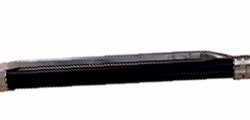

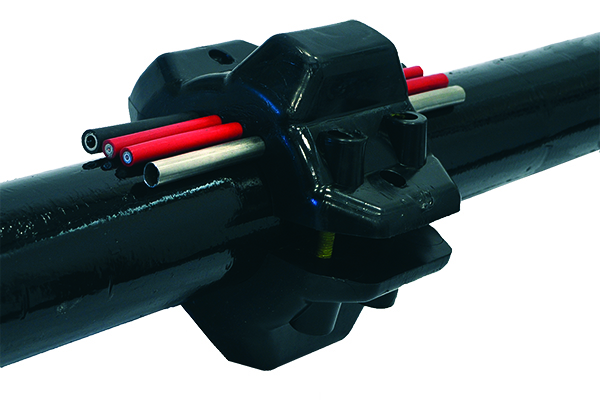

Umbilical Protectors

Essential Protection for the Lifelines of Deep-Sea Operations

Umbilical cables are the vital conduits of power, fluid injection, control, and communication in deep-sea drilling. As offshore production moves farther from shore, the risk of umbilical damage and the associated costly downtime increases dramatically.

FET’s umbilical protectors are engineered to safeguard these critical systems. Designed to retain and shield cables within marine risers, each assembly features a specialty strap collar that custom-fits the outer diameter and durometer of individual cables. Built from noble, corrosion-resistant materials, these protectors offer long-term durability and high reusability in harsh subsea environments.

Part of our trusted Cannon Services product line and the broader MultiLift artificial lift solutions catalog, these protectors are built to perform where it matters most.

Key Benefits

- Prevents damage to umbilicals during installation and retrieval

- Reduces workover costs through high reusability

- Performs reliably in complex offshore and subsea well designs

- Speeds up installation, minimizing downtime and labor costs

Features

- Interchangeable designs for tubing sizes from 3.5″ to 13.75″ and larger

- Strap collar system custom-fitted to cable dimensions and durometer

- Tailored for deployment over production tubing and drill pipe connections

- Quick installation using air-driven hydraulic tools

- Available in corrosion-resistant alloys and specialty steels

Applications

- Offshore subsea completions

- Power and control umbilicals

- Chemical injection lines

- Communication and monitoring systems

Vacuum Insulated Tubing Solutions

Vacuum Insulated Tubing Solutions

VIT Protection

Precision Protection for Vacuum-Insulated Tubing and Control Lines

FET’s patented VIT protectors are engineered to safeguard your most critical downhole components. Designed to secure vacuum-insulated tubing (VIT) sleeves while stabilizing adjacent control lines, these protectors ensure safe, efficient installations in even the most complex offshore and subsea environments.

With customizable configurations for tubing, casing, and control lines, our VIT protectors offer exceptional reusability, helping reduce project costs and extend equipment life.

Part of the trusted Cannon Services product line and our comprehensive MultiLift artificial lift solutions, these protectors are built for performance and longevity.

Key Benefits

- Protects VIT sleeves from damage during installation and retrieval

- Reduces recompletion costs through high reusability

- Performs reliably in challenging offshore and subsea well designs

Features

- Interchangeable designs for tubing sizes from 2.375″ to 13.75″ and beyond

- Custom-built to support multiple control line configurations

- Tailored for various connection and sleeve combinations

- Available in corrosion-resistant alloys and specialty steels

Applications

- Securing VIT sleeves

- Protecting control lines

- Ideal for offshore and subsea completions

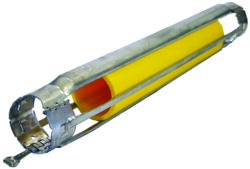

VIT Sleeves

Engineered Insulation for Demanding Downhole Environments

Forum’s vacuum-insulated tubing (VIT) sleeves are designed to deliver superior thermal insulation at VIT connection points where heat loss is most critical. Built to perform in a wide range of wellbore conditions, these sleeves help maintain thermal stability while supporting multiple tubing, casing, and control line configurations.

Crafted for multiple use cycles, our VIT sleeves offer long-term durability and significant cost savings on future workovers. Whether you’re operating in deepwater or high-temperature environments, these sleeves are a reliable solution for protecting your thermal integrity.

Part of the Cannon Services product line and our extensive MultiLift artificial lift solutions catalog, FET’s VIT sleeves are trusted by operators worldwide.

Key Benefits

- Preserves thermal integrity at VIT connections

- Reduces recompletion costs through high reusability

- Performs reliably in complex offshore and subsea well designs

Features

- Interchangeable designs for tubing sizes from 2.375″ to 13.75″ and larger

- Custom-engineered to support a wide range of VIT connection combinations

- Precisely dimensioned for targeted insulation performance

- Molded from high-performance materials for thermal efficiency and wellbore compatibility

Applications

- Critical thermal stability operations

- Offshore and subsea completions

- High-temperature well environment

Splice / Gauge Protectors

Splice & Gauge Protectors: Reliable Protection for Critical Downhole Connections

FET’s splice protectors, part of our trusted Cannon Services product line and MultiLift artificial lift solutions, are engineered to safeguard cable splices from mechanical stress during installation, retrieval, and long-term operation in the wellbore.

With a wide range of configurations and materials, we build our protectors to meet the demands of complex well designs, including high-angle and offshore/subsea environments.

Key Benefits

- Prevent costly damage to cable splices during installation and workovers, ensuring uninterrupted performance of ESPs, sensors, and other downhole systems.

- Our high-durability designs are reusable across multiple well cycles, helping operators cut costs on recompletions and reduce non-productive time.

- From deepwater to deviated wells, our protectors are built to perform in the most challenging environments with a fast, secure installation that minimizes rig time.

Key Features

- Flexible Fit: Interchangeable designs for tubing ODs from 2.375″ to 13.75″ +

- Versatile Configurations: Flat-to-flat, round-to-round, and flat-to-round splice compatibility

- Broad Compatibility: Supports TEC, hydraulic lines, fiber optics, and more

- Custom-Built: Tailored to your well’s specifications

- Deployment Options: Mid-joint or cross-coupling assemblies

- Material Choices: Available in corrosion-resistant alloys and specialty steels

- High-Angle Ready: Designed for complex well trajectories

Applications

- Electric Submersible Pump (ESP) cable splices

- Heater cable splices

- Downhole pressure/temperature transducer Y-blocks

- TEC and fiber optic splices

Protect your investment below the surface.

FET’s splice protectors deliver the durability, adaptability, and performance your operations demand well after well.

Guards

Standoff Guards for Cable and Line Protection

FET’s Standoff Guards, part of the Cannon Services product line and our broader Multilift artificial lift solutions catalog are engineered to protect cables and lines as they pass over large outer diameter (OD) equipment during installation or retrieval. These guards use augmented channels to shield critical components from abrasion and impact, ensuring safe and efficient completions.

Each standoff guard is customized to fit its associated equipment, providing a tailored solution for your specific well configuration. Installation is fast and straightforward, utilizing air-driven hydraulic tools to compress collars and secure taper pins, thereby minimizing rig time and maximizing operational efficiency.

FET’s standoff guards are part of our Cannon Services product line and extensive MultiLift artificial lift solutions catalog.

Key Benefits

- Custom Fit: Designed to match specific well designs and equipment profiles.

- Refurbishable: Extend product life and reduce secondary workover costs.

- Flexible Solutions: Supports both cost-effective and premium configurations to meet budget and performance needs.

- Quick Installation: Streamlined setup reduces time on location.

Features

- Fits tubing sizes from 2.375″ to 10.75″ OD and larger

- Compatible with tubing and flow couplings

- Multiple designs to accommodate various cable and line configurations

- Available in corrosion-resistant alloys and specialty steels

- Secure taper pin connection ensures a tight, reliable fit

Applications

- Safety valves

- Chemical injection mandrels

- Gas lift mandrels

- Flow control valves

Explore how FET’s Standoff Guards can enhance cable protection, reduce equipment wear, and streamline your completion operations.

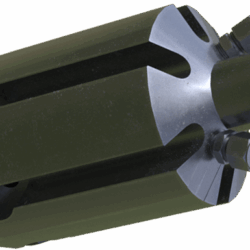

Chemical Injection

Corrosion Protection with Chemical Injection Centralizer

FET’s Chemical Injection Centralizer, part of our Multilift artificial lift solutions portfolio, offers a more innovative, more efficient approach. Installed below the ESP motor, it functions as both a centralizer and a chemical injection system, delivering uniform 360° dispersion for consistent chemical treatment and enhanced ESP performance.

By ensuring even spacing between the motor and casing, the centralizer promotes balanced fluid flow, preventing hotspots and improving motor cooling. This dual functionality not only protects your ESP system but also boosts its reliability and uptime.

FET’s chemical injection centralizers are part of our extensive Multilift artificial lift solutions catalog.

Key Benefits

- Optimized Chemical Treatment: Uniform 360° dispersion minimizes corrosion risks associated with uneven injection.

- Enhanced ESP Cooling: Equal flow paths improve thermal regulation around the motor.

- Improved System Reliability: Reduces the chance of damage during installation and operation.

- Increased Uptime: Proper centralization enhances ESP performance and longevity.

- Operational Efficiency: Minimizes chemical waste and the risk of emulsion-related issues.

Features

- Compatible with all downhole ESP systems

- Dual chemical injection line connections

- Six nozzles for full 360° spray coverage

- Integrated check valve system

- Customizable tubing sizes and thread types

- Minimum injection pressure: 500 psi

- Flow rates: ¼-inch line – up to 3.5 GPM; ⅜-inch line – up to 7 GPM

- Withstands differential back pressure up to 5,000 psi

Applications

- Casing sizes of 5 inches or larger

- Vertical, deviated, and horizontal wells

- ESP installations inside liner applications

- Point-of-departure chemical injection scenarios

Discover how FET’s Chemical Injection Centralizer can help you achieve more effective corrosion control while improving ESP system performance and operational efficiency.

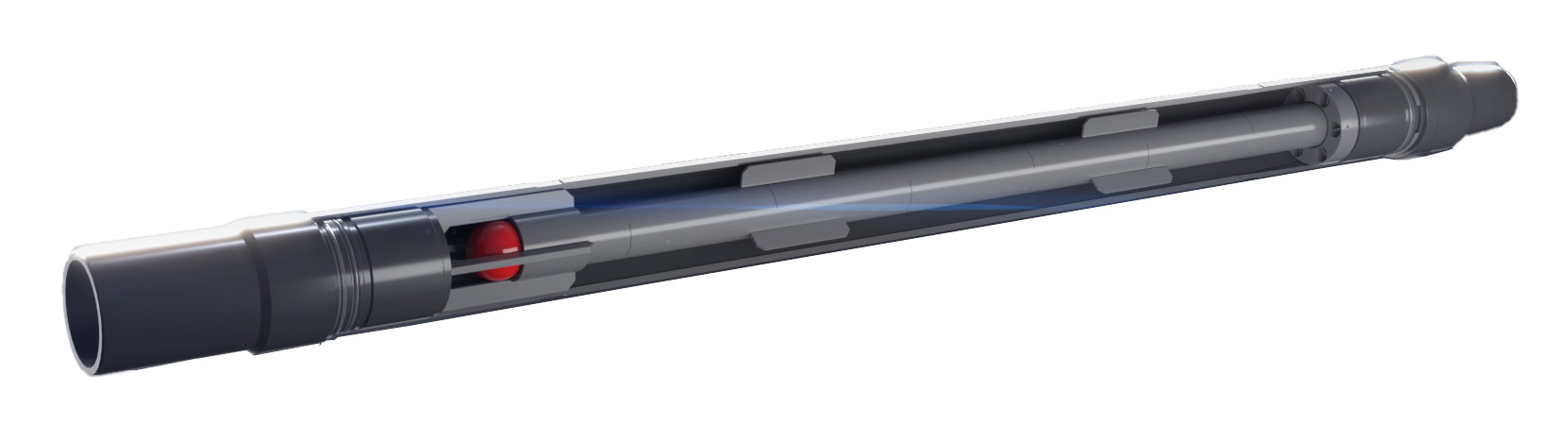

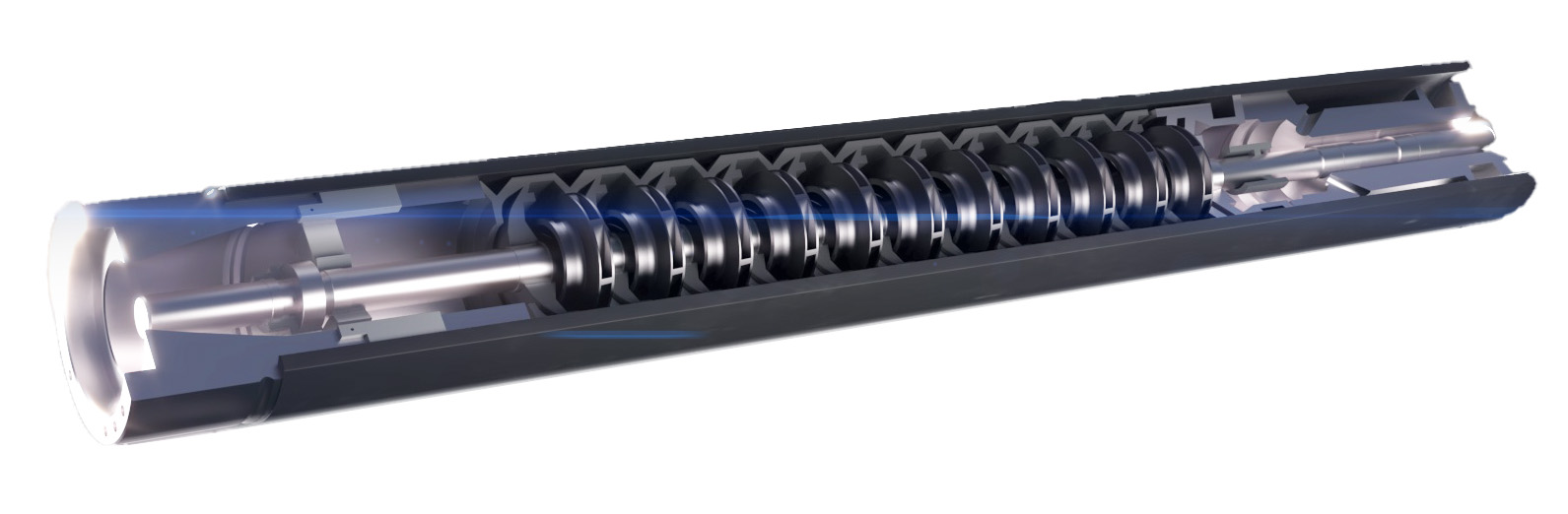

ESP SandGuard

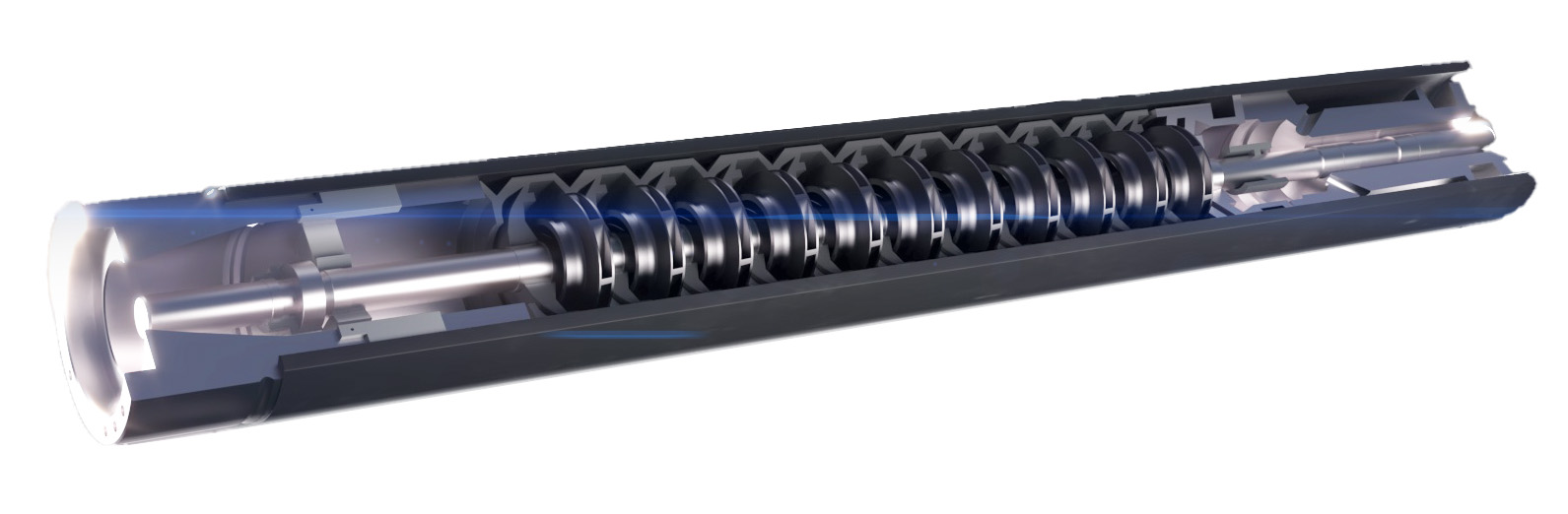

SandGuard® Advanced Sand Management for Extended ESP Life

SandGuard® is a groundbreaking multi-lift solution from FET designed to eliminate the leading causes of Electric Submersible Pump (ESP) failures. With thousands of successful installations, SandGuard has proven its ability to dramatically extend ESP run times in even the harshest, sand-laden environments.

How SandGuard Works

SandGuard captures and isolates fallback sand during pump shutdowns, preventing it from damaging the pump during restarts. Its innovative auto-flush design ensures a clean, debris-free start every time, minimizing wear and maximizing pump longevity.

Key Benefits of SandGuard

- Extends ESP life by up to 1,200%

- Prevents sand fallback with continuous auto-flush functionality

- Ensures clean pump restarts by capturing all post-shutdown debris

- Reduces startup stress on ESPs, promoting longer operational life

- Eliminates annulus communication, removing risks of failure or fluid recirculation

- Compatible with all ESP flow rates

- Built to endure extreme downhole conditions

- Available with standard or custom connections to match your production tubing

Versatile Applications

SandGuard is engineered for flexibility and can be deployed across a wide range of well types, including:

- ESP installations

- Horizontal or deviated wells

- Offshore and onshore operations

Why Choose SandGuard?

SandGuard is the cornerstone of FET’s Multilift Solutions sand management system. Its flushable, reusable design makes it a favorite among operators seeking reliable, long-term sand control. Whether you’re working with a specific casing size or a unique well configuration, SandGuard delivers consistent performance and adaptability.

Unlike other solutions, SandGuard installs easily at the pump discharge and requires no complex modifications. Its proven track record and simple deployment make it the go-to choice for operators looking to protect their ESP investments.

In Mississippian Lime wells, SandGuard increased ESP runtimes by over 1,200% compared to unprotected wells. Backed by more than 3,000 installations, the results demonstrate its effectiveness.

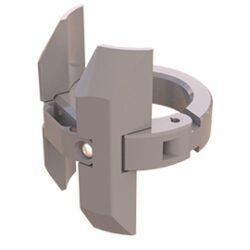

Motor Lead Extension (MLE) Protectors

MLE Cable Protectors for Enhanced ESP Reliability

Though compact and often overlooked, Motor Lead Extension (MLE) cables play a vital role in downhole operations, serving as the critical link between the main power cable and the ESP motor. To ensure these flat cables perform reliably under demanding conditions, FET’s MLE Cable Protectors are engineered for a precise fit and superior protection.

Designed with a low running profile and optimized deployment location, these protectors reduce the risk of cable damage during installation and retrieval. The result is improved ESP system reliability and a significant reduction in costly MLE and pothead failures.

Part of the Cannon Services product line and the broader FET Multilift Solutions catalog, our MLE protectors are built for performance, durability, and ease of use across a wide range of well environments.

Key Benefits

- Enhanced Cable Protection: Shields MLE cables during ESP conveyance to prevent mechanical damage.

- Reduced Failure Risk: Low-profile design minimizes snagging and stress points.

- Improved Project Economics: High reusability lowers long-term operational costs.

Features

- Constructed from 316 stainless steel for corrosion resistance

- A special retention clip accommodates up to two capillary tubes

- Anti-rotation bolt prevents protector movement during operation

- Compatible with all ESP sizes and manufacturers

Applications

- Vertical, deviated, and horizontal wells

- Conveyance inside liner casing

- Steam-Assisted Gravity Drainage (SAGD) wells

- Geothermal wells

- Offshore and subsea wells

Discover how FET’s MLE Cable Protectors can safeguard your ESP investment and improve system uptime in even the most challenging environments.

GasGuard®

Tackle Gas Slugging Before It Disrupts Production

Gas slugs can form under a wide range of production conditions, whether due to shifting reservoir dynamics, enhanced oil recovery (EOR/IOR) strategies, or fluctuating production rates. Regardless of the cause, slugging remains one of the most persistent and costly challenges in the oil and gas industry.

This issue is particularly critical in unconventional wells that utilize artificial lift technologies, such as electric submersible pumps (ESPs). Gas slugs can lead to lost production, equipment damage, and increased operational costs, ultimately delaying the incremental production that optimized ESP systems are designed to capture.

The Best Solution Is Prevention

That’s where FET Multilift Solutions steps in. Our patent-pending GasGuard® neutralizes gas slugs before they reach the ESP system. By breaking down and infusing gas slugs into the liquid stream, GasGuard ensures a smooth, uninterrupted flow through the pump. The result? A more stable production stream with higher liquid content, improved motor cooling, and enhanced ESP performance with fewer shutdowns and lower maintenance costs.

With its streamlined, no-moving-parts design, GasGuard sets a new standard in gas slug protection.

Benefits

- Easy installation and retrieval via the production string

- Boosts ESP motor cooling efficiency

- Reduces equipment costs with a simplified design

- Disrupts gas slugs before they reach the pump intake

- Enhances pump runtime and overall performance

- Minimizes shutdowns caused by gas lock

- Complements or reduces reliance on costly ESP gas-handling devices

Key Features

- No moving parts for enhanced reliability

- Modular design suited for extreme environments

- Integrates with SandGuard™, Cyclone™, and chemical injection centralizers

Applications

- Unconventional wells

- Steam-assisted gravity drainage (SAGD) wells

- Wells experiencing severe gas slugging