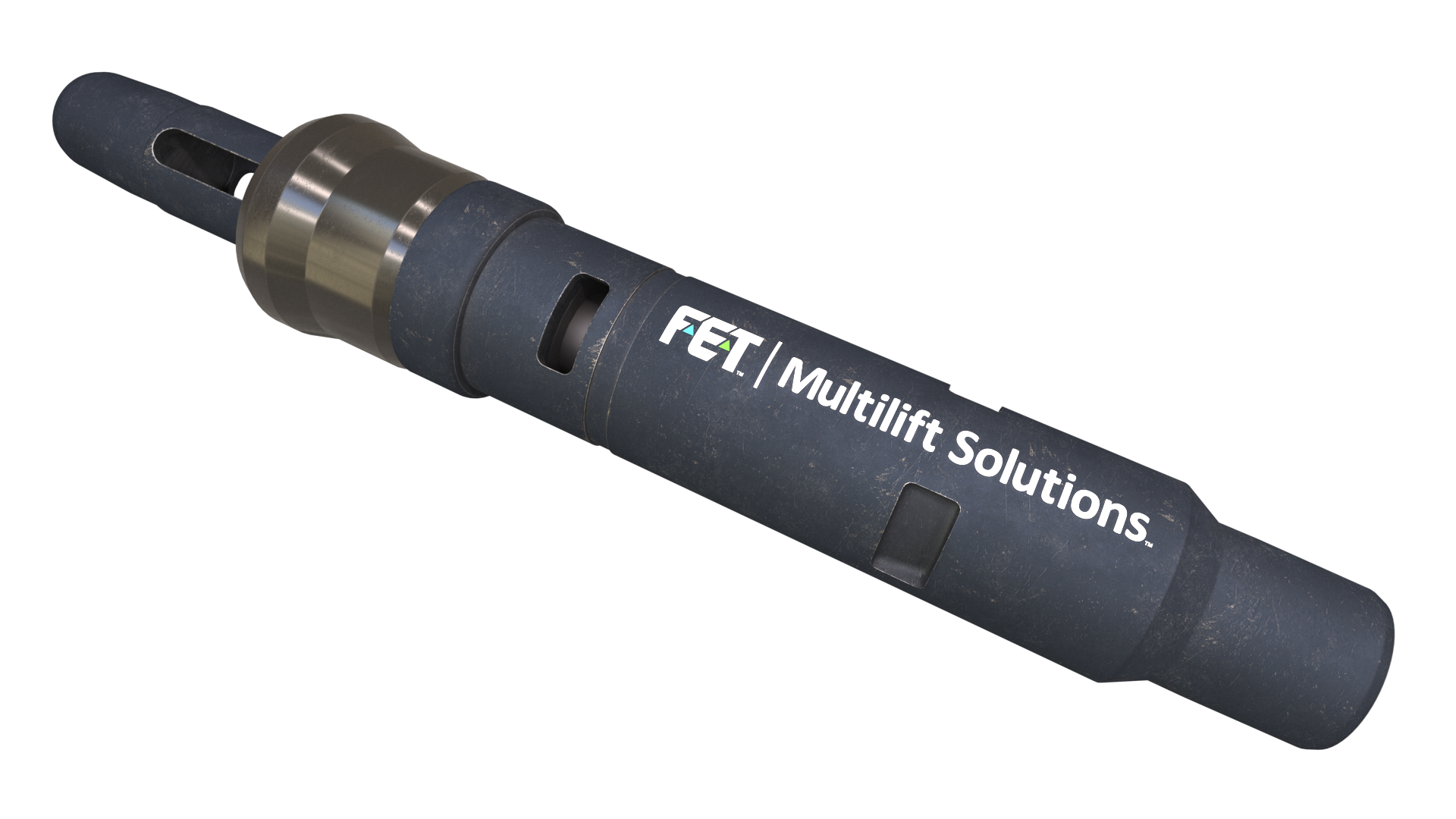

Cyclone ESP: Advanced Sand Protection with Vortex Technology

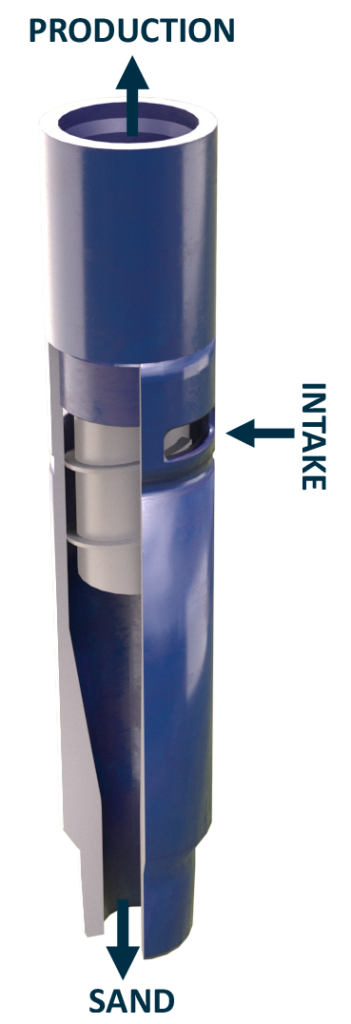

Cyclone ESP harnesses the power of proven vortex technology to deliver superior sand protection for electric submersible pumps (ESPs). Designed for versatility, it performs reliably in onshore, offshore, deviated, and horizontal wells in protecting your equipment, extending pump run life, and significantly reducing lease operating expenses.

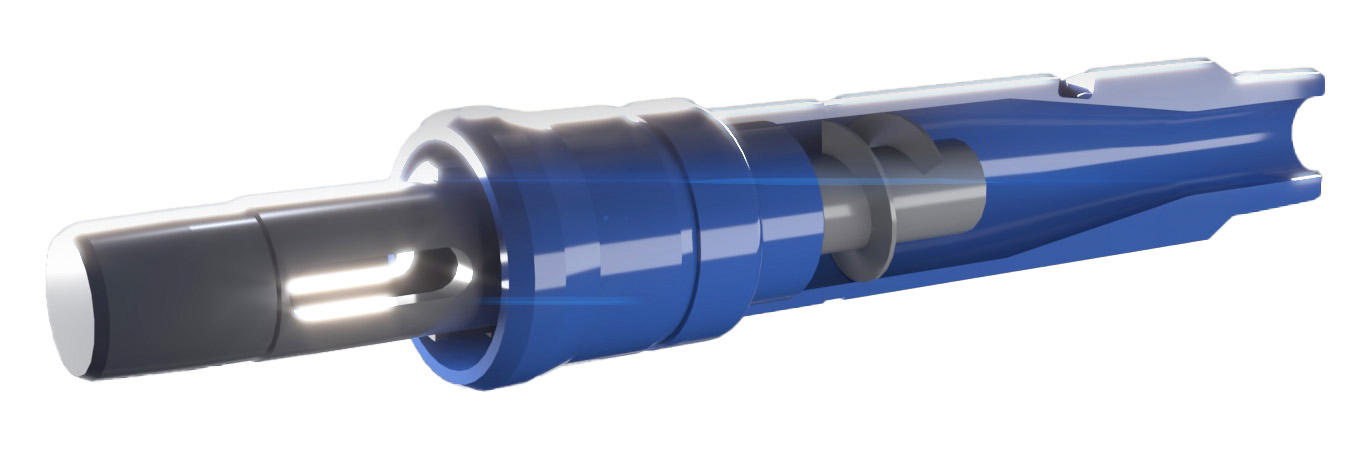

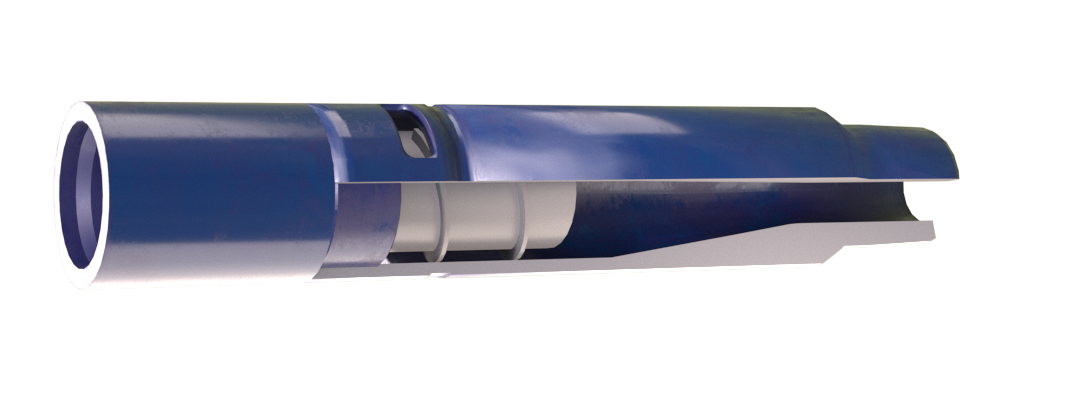

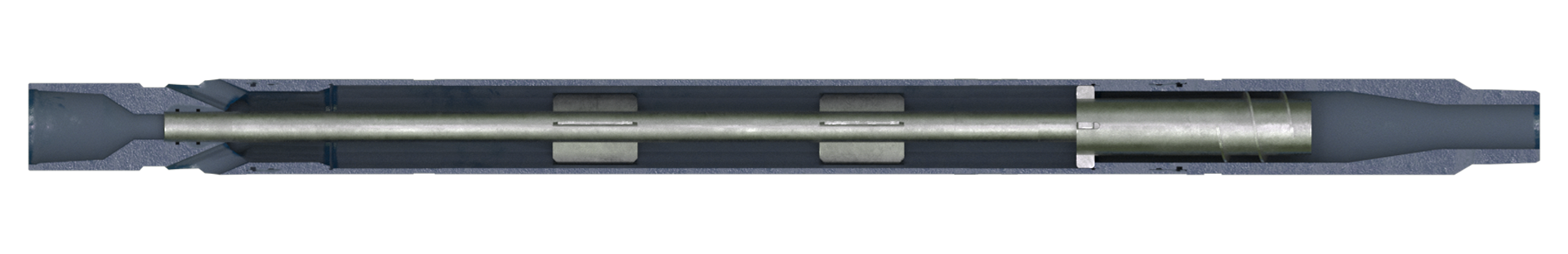

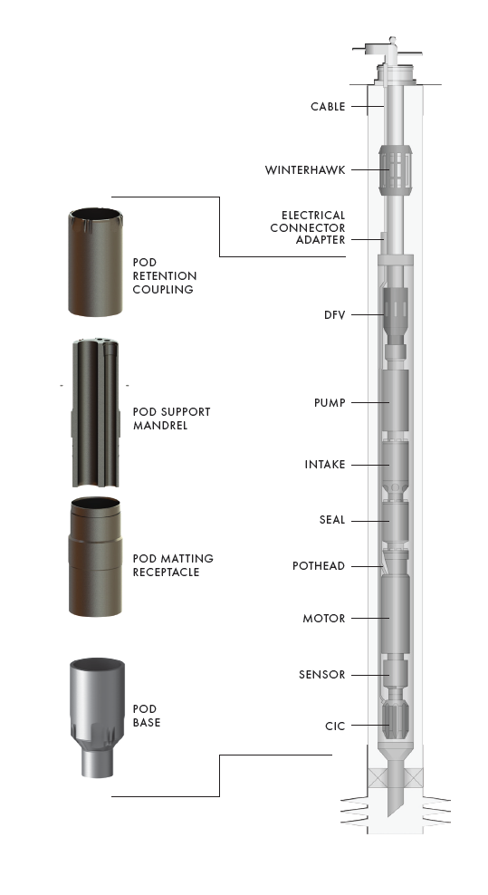

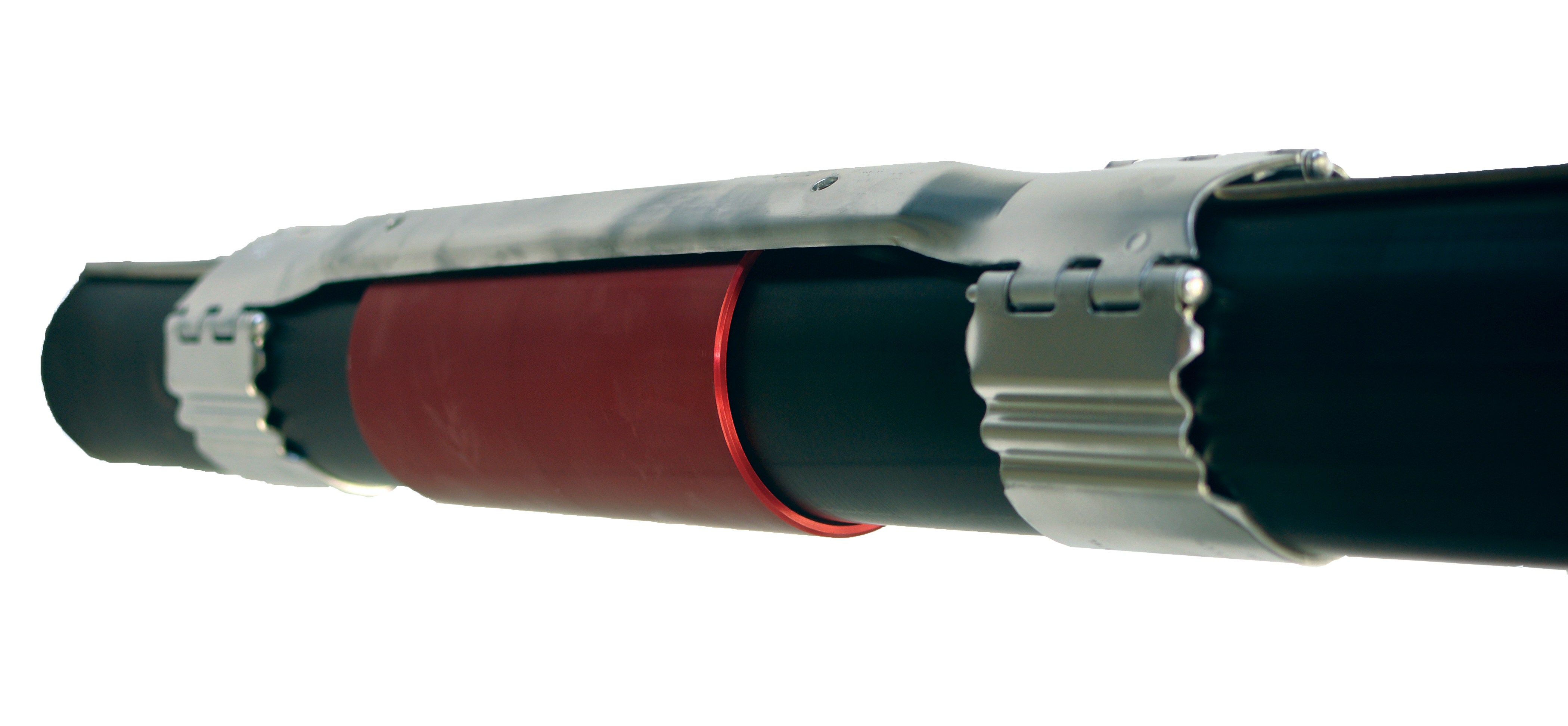

With a universal one-size design, Cyclone easily retrofits into any ESP well. Installed directly below the pump, it requires no downhole preparation, making deployment fast and hassle-free. Its high-efficiency centrifugal action separates a broader range of sand grain sizes than traditional sand screens, directing clean fluid to the pump and diverting solids to a tailpipe below.

Constructed from specialized metallurgy and featuring no moving parts, Cyclone avoids the erosion, plugging, and maintenance issues common with conventional sand control methods. The result is a robust, low-maintenance solution that delivers consistent performance in even the harshest environments.

Key Features and Benefits

- Superior Sand Protection: Shields ESPs from abrasive damage.

- Extended Pump Life: Reduces wear, increasing uptime and reliability.

- Lower Operating Costs: Minimizes workovers, replacements, and lost production.

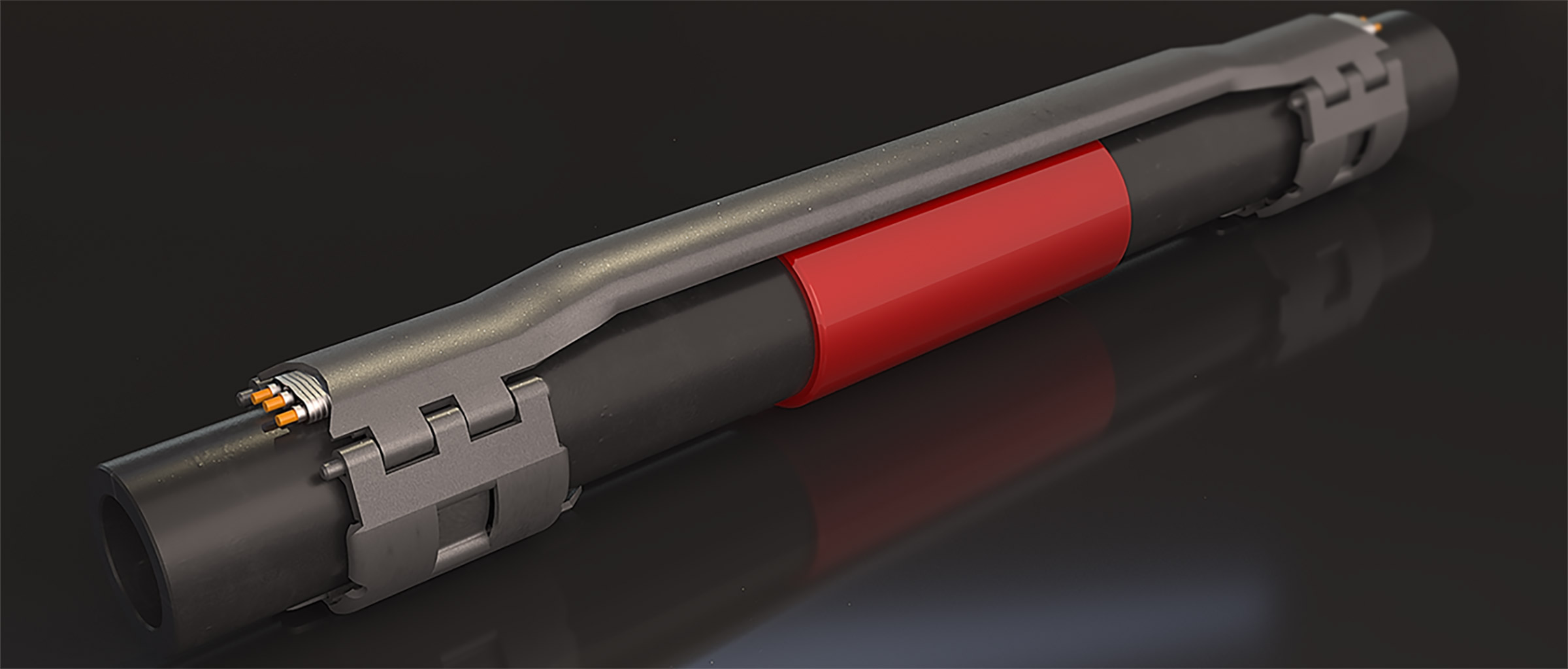

- Universal Fit: One size fits all casing weights—no custom parts needed.

- Quick & Easy Installation: No need to rotate the motor or tailpipe.

- Field-Serviceable: Rubber elements can be changed on-site.

- High Reusability: Enables fast changeouts and reruns without leaving the rig floor.

Discover how Cyclone ESP can enhance your sand control strategy, delivering efficiency, durability, and peace of mind in every well.